Among engineering machinery, excavators have become indispensable equipment in infrastructure construction, mining, urban and rural transformation, etc. due to their excellent operating capabilities and wide application scenarios. One of the core supports for excavator performance is the stability and durability of its undercarriage system. Track rollers are the key parts of the undercarriage that are responsible for supporting the weight of the entire machine and guiding the movement of the track. The quality of the track roller directly determines the operating efficiency, life and maintenance cost of the excavator under various complex working conditions.

كمحترف مُصنِّع بكرات الجنزير that has been deeply engaged in the manufacture of excavator undercarriage parts for many years, GFM has become the preferred supplier of track rollers for many excavator parts manufacturers and maintenance markets around the world with its strong manufacturing strength, strict quality control system and in-depth understanding of the global market.

جدول المحتويات

The role and structural analysis of track rollers

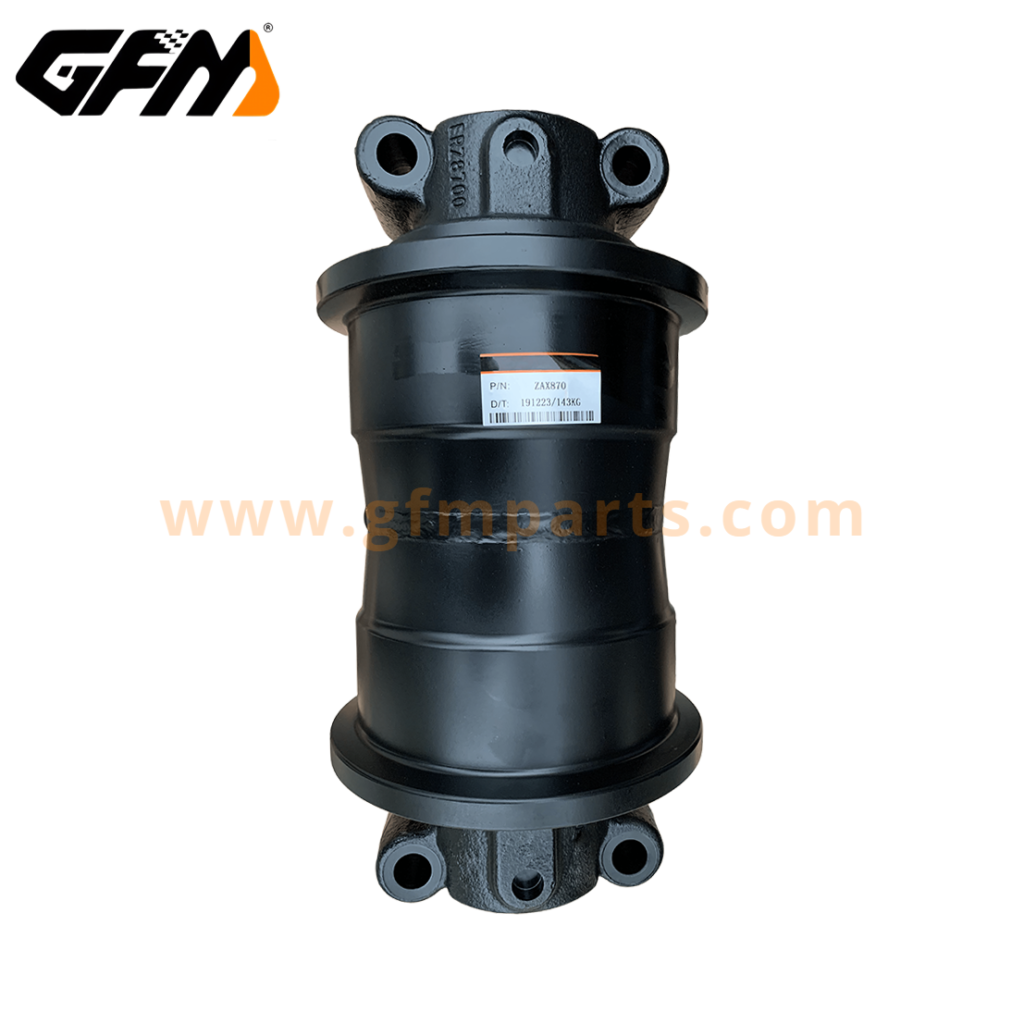

The track roller is one of the core components in the undercarriage system of track excavators. It is installed under the track and mainly plays the role of supporting the weight of the entire machine, guiding the operation of the track, alleviating impact loads, and keeping the equipment running smoothly.

A high-quality الأسطوانة السفلية للحفارة can not only effectively improve the travel efficiency of the equipment, but also extend the life of the whole machine and reduce the cost of later maintenance.

The basic structure of the track roller includes:

- The wheel body (shell): generally made of high-strength alloy steel forging, with good impact resistance and fatigue resistance.

- Bearing system: To support the core part of the wheel body, deep groove ball bearings or roller bearings are generally used, which must be tightly sealed and run smoothly.

- Sealing structure: double-channel floating oil seals or high-pressure seals are mostly used to ensure that the bearings are not invaded by mud and water, thereby extending the service life.

- Heat treatment layer: The outer ring of the wheel body is treated with high-frequency quenching, and the quenching depth and hardness directly affect the wear resistance.

Common causes of damage:

- Improper track tensioning leads to concentrated force

- Failure of the seal causes water corrosion of the bearing

- Uneven heat treatment leads to increased wear

- The hardness of the wheel body material does not meet the standard and causes deformation

Therefore, it is very important to choose a track roller manufacturer with mature manufacturing technology and perfect testing process.

GFM’s core advantages in bottom roller manufacturing

GFM is committed to providing high-quality rollers that meet global standards and adapt to a variety of working conditions. Its manufacturing advantages are reflected in the following aspects:

Factory strength and equipment configuration:

GFM has a modern factory building of more than 10,000 square meters and has introduced a number of fully automatic CNC processing production lines, including high-precision vertical lathes, CNC grinders, automatic assembly lines and other equipment to ensure that each roller meets the unified standard.

اختيار المواد الخام:

All rollers are made of high-quality alloy structural steel. The raw materials are purchased from well-known steel companies at home and abroad, and component analysis and ultrasonic flaw detection are carried out to ensure that there are no hidden dangers such as interlayers and cracks.

Heat treatment stability:

GFM uses a dual heat treatment process of high-frequency quenching + medium-frequency tempering to effectively ensure that the surface hardness of the wheel body reaches HRC48-55, and the quenching depth is not less than 6mm, taking into account both wear resistance and toughness.

Customization capability:

GFM can provide matching models according to different brands of excavators (such as Komatsu, Hitachi, Carter, Hyundai, Sany, etc.), and also supports customization according to drawings and samples, which is suitable for a variety of working conditions such as wetlands, mines, and high-cold areas.

Technical team guarantee:

GFM has a technical R&D team composed of more than 30 mechanical engineers, which can provide all-round support such as structural optimization, material upgrades, and strength calculations.

Production process and testing process of GFM track rollers

Although the track rollers are small, every process must be done carefully. GFM adopts strict process flow and high-standard quality inspection system to ensure that each track roller has stable performance and excellent quality.

Core production process:

- Forging: Use high-temperature die forging technology to ensure that the internal structure is dense and free of shrinkage cracks.

- Rough machining: Turn the initial contour to facilitate subsequent processing.

- Heat treatment: High-frequency quenching increases the hardness of the wheel rim, and tempering eliminates stress.

- Finishing: CNC lathe processes the bearing hole and installation dimensions, with a tolerance within ±0.01mm.

- Assembly inspection: Use special tools to assemble the bearing and seal ring, and perform a rotation resistance test.

- Surface treatment: Spray a double layer of anti-rust paint to improve corrosion resistance.

Inspection links:

- Dimension inspection: Three-coordinate measuring instrument ensures that the structural dimensions are consistent with the drawings

- Hardness inspection: Rockwell hardness tester detects the hardness of the wheel surface and rim

- Sealing test: The oil pressure test device simulates operation to check whether the sealing performance is qualified

- Salt spray test: Continuous spraying in a salt spray environment for ≥96 hours to test the anti-rust effect of the coating

How to choose high-quality track rollers

For end customers and engineering machinery maintenance companies, when purchasing track rollers, they are often confused by the situation of “same appearance and huge price difference”. Here are some practical judgment methods:

Confirm the model and specifications

- Clear the host brand and model (such as PC200-8, CAT320)

- Check the host undercarriage drawings or consult the manufacturer for specific dimensions

Observe the hardness of the wheel rim

- High-quality supporting wheels should have a high wheel rim hardness (about HRC50)

- Can be tested with the help of a portable hardness tester

Judge the material process

- Integral forged wheel body > welded assembled wheel body

- Whether there are traces of heat treatment process (quenching discoloration area)

Check the sealing structure

- It is recommended to use a double floating oil seal structure, which has better dust and water resistance

- Check whether grease is filled and there is no oil leakage

Evaluate the manufacturer’s qualifications and cases

- Whether it has passed ISO9001 certification and whether there are real customer cooperation cases

- Whether it can provide proofing, batch processing, and technical drawing support

GFM’s influence in the global market and customer service system

After years of deep cultivation and accumulation, GFM’s supporting wheel products have been exported to more than 30 countries and regions around the world, and a complete customer service network has been established.

Overseas market layout:

- European market: cooperate with engineering machinery maintenance companies in Germany, Italy, Poland and other countries to provide them with OEM replacement products

- Middle East and Africa: high temperature resistant and dust resistant track roller products are exported to the UAE, Saudi Arabia and South Africa

- Southeast Asia and South America market: develop rust-resistant products for high humidity and continuous working environments

Customer service system:

- Fast delivery capability: conventional models are in stock, and customized products are delivered within 7 to 15 days

- After-sales technical support: can provide installation guidance, fault analysis, and regular inspection services

- Sample proofing service: support 3D drawings to be quickly produced Like, meet the test verification

- Multilingual service: Sales and technical teams are equipped with Chinese, English and Spanish customer service capabilities

Real customer feedback:

“We have been using GFM’s track rollers for 3 years, and there has been no oil leakage or breakage so far. It performs very well among similar products.”-German customer Company A

“Even in a mining environment with continuous operation for 12 hours, GFM’s track rollers still run smoothly, and are truly wear-resistant and pressure-resistant.”-South American customer Company B

| احصل على عرض أسعار سريع ومجاني | البريد الإلكتروني: henry@gfmparts.com | واتساب: +86 17705953659 |

GFM is not only a track roller manufacturer, but also an expert in excavator undercarriage system solutions. From material selection to process, from standardized mass production to flexible customized services, GFM has always been customer-oriented, driven by technological innovation, and quality control as its lifeline, and continues to provide stable and reliable track roller products to global customers.

Whether you are a complete machine factory, maintenance company, or engineering construction unit, as long as you have high-quality track roller needs, GFM can provide you with stable product guarantees and considerate technical services. Welcome to contact GFM to start a new chapter of efficient collaboration.