Rodillo tensor de orugas para excavadora Liebherr R944

- Calidad del producto garantizada

- Gran suministro

- Precios competitivos

- La mayoría de marcas y modelos

- Equipo de atención al cliente servicial

- Soporte técnico profesional

Compartir

GFM ha desarrollado rodillos guía de alta calidad especialmente para la excavadora Liebherr R944 con el fin de mejorar la eficiencia de trabajo y la vida útil. Como componente importante del sistema de desplazamiento de las orugas, el rueda guía de la oruga de la excavadora cumple la doble función de guiar y tensar la oruga, y es la clave para mantener el equipo funcionando sin problemas.

Nuestras ruedas guía están hechas a medida para el Liebherr R944 y se adaptan perfectamente a la geometría del chasis y a sus necesidades de carga.

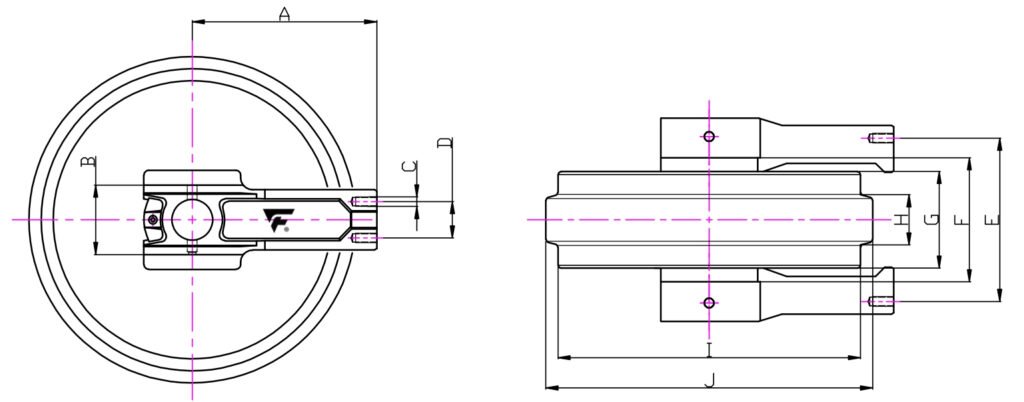

- Coincidencia precisa: el diámetro, el ancho, la posición del orificio del cojinete y la posición del orificio del soporte se fabrican de acuerdo con los estándares de fábrica originales R944.

- Aleación de alta resistencia: se selecciona acero tratado térmicamente para lograr una mayor resistencia y ser menos propenso a la deformación.

- Cojinetes de alta calidad: Equipados con cojinetes de rodillos suecos importados, con gran capacidad de carga y sellos fiables a prueba de polvo.

- Fortalecimiento de la superficie: El anillo exterior del rodillo está nitrurado o carburizado y la resistencia al desgaste y la resistencia a la corrosión se mejoran significativamente.

- Diseño de reducción de vibraciones: La estructura interna está optimizada para dispersar eficazmente la fuerza del impacto y reducir el impacto en el chasis y el mecanismo de dirección.

- Fácil de mantener: Los orificios de lubricación estándar están reservados y el mantenimiento diario solo requiere un simple llenado de grasa para prolongar la vida útil.

Descripción del Producto

- Cantidad mínima de pedido: 1 pieza

- Método de pago: Transferencia bancaria

- Marca: GFM

- Condición: Nuevo

- Color: Amarillo, negro o personalizado

- Plazo de entrega: 30 días

- Garantía: 1 año

- Servicio: OEM o ODM

- Lugar de origen: Fujian, China

- Solicitud: Excavador

- Embalaje: Palet de madera de exportación estándar

Características

- Durable:Diseñado para soportar condiciones difíciles para un rendimiento duradero.

- Ajuste perfecto: Diseñado para una fácil instalación en varios modelos de excavadoras y bulldozers.

- Trabajo pesado: Soporta cargas pesadas para un funcionamiento suave y estable.

- Suave y silencioso:Minimiza la vibración para un movimiento más suave y una mejor tracción en todos los terrenos.

- Bajo mantenimiento: Autolubricante para menor mantenimiento y mayor tiempo de funcionamiento.

- Resistente a la intemperie: Se comporta bien en cualquier clima, es resistente al óxido y a las temperaturas extremas.

Presupuesto

Modelos de productos

Proceso de producción

Desde el diseño hasta la entrega, cada etapa del proceso de nuestros productos se controla estrictamente para garantizar su estabilidad y durabilidad. A continuación, se presenta una introducción al flujo básico del proceso:

- Inspección de materia prima

- Seleccione aleaciones de alta calidad y materiales de alta resistencia, y sometámonos a estrictos análisis de composición química y pruebas de propiedades mecánicas.

- Los registros de datos de pruebas claros garantizan que los materiales cumplan plenamente con los requisitos estándar.

- Mecanizado y moldeo CNC

- Utilice máquinas herramienta CNC de alta precisión para el mecanizado de precisión para garantizar la precisión dimensional de las piezas.

- El proceso de moldeo se ha optimizado repetidamente para que la superficie del producto sea lisa y evitar problemas de desgaste causados por defectos de mecanizado.

- Tratamiento de superficies y tratamiento térmico

- Según los diferentes entornos de aplicación, seleccione métodos de tratamiento de superficie adecuados, como pulverización, galvanización, etc., para mejorar la resistencia a la corrosión del producto.

- El proceso de tratamiento térmico mejora la estructura interna del material, aumentando su dureza y resistencia al desgaste.

- Inspección y pruebas estrictas

- Cada proceso tiene un enlace de inspección especial para garantizar que los productos no calificados nunca salgan de la fábrica.

Al mismo tiempo, a través de pruebas simuladas de condiciones de trabajo en el sitio, se garantiza que la rueda loca funcionará bien en el uso real.

- Cada proceso tiene un enlace de inspección especial para garantizar que los productos no calificados nunca salgan de la fábrica.

Embalaje y envío

Ventajas de la fábrica

GFM PARTS profesional fabricante de ruedas tensoras para excavadoras Contamos con una larga experiencia en fabricación y un sólido equipo técnico, y todos nuestros equipos han alcanzado el nivel internacional más avanzado. A continuación, presentamos brevemente las ventajas de nuestra fábrica:

- Equipo de producción avanzado: La introducción de múltiples centros de mecanizado CNC líderes a nivel internacional y equipos de prueba totalmente automáticos garantiza que cada producto se procese y pruebe con precisión.

- Sistema de gestión de calidad: Operamos estrictamente de acuerdo con el sistema de calidad ISO, y existen registros detallados desde la aceptación de la materia prima hasta la entrega del producto terminado para garantizar que cada vínculo sea rastreable y que la calidad del producto se base en evidencia.

- Equipo profesional de I+D: Tras años de desarrollo tecnológico y desarrollo de mercado, contamos con un equipo de I+D experimentado y capacitado. Podemos responder con rapidez a las necesidades de nuestros clientes y optimizar continuamente el diseño de nuestros productos y el flujo de procesos.

- Alta capacidad de personalización: La fábrica puede ajustar la línea de producción con flexibilidad para procesar lotes pequeños y medianos, así como pedidos a gran escala. Ya sean materiales especiales, procesos complejos o diseños únicos, se pueden personalizar según las necesidades.

Ventajas de los servicios personalizados

GFM entiende las necesidades especiales en diferentes condiciones de trabajo y ofrece soluciones personalizadas flexibles e integrales para ayudarle a lograr el mejor rendimiento:

- Selección de materiales: Se puede proporcionar acero de aleación convencional, aleación de alta tenacidad o acero resistente a altas temperaturas según las condiciones de trabajo para cumplir con entornos extremos.

- Recubrimiento especial: Recubrimiento en aerosol opcional anticorrosión, antiadherente o resistente a altas temperaturas, adecuado para condiciones de trabajo complejas como playa, desierto, altas temperaturas, etc.

- Optimización estructural: admite mejoras de diseño como el aumento de la carrera de tensión, la ampliación de la superficie de apoyo y la mejora de la estructura de sellado para mejorar el tensado de la oruga y el rendimiento de guiado.

- Embalaje y logística: proporcionamos película a prueba de humedad, relleno antisísmico y embalaje de caja de madera personalizado para garantizar que las piezas estén intactas durante el transporte de larga distancia.

- Dibujos y números exclusivos: Marcar según número de obra del cliente o número de proyecto para facilitar la posterior gestión de repuestos y el seguimiento de pedidos por lotes.

Sugerencias amigables y consejos prácticos

Como un fábrica de piezas de excavadorasNo solo ofrecemos productos de alta calidad, sino que también esperamos compartir algunos consejos sobre su uso y mantenimiento. rodillo tensor de la oruga con los clientes para ayudarle a administrar el equipo más fácilmente.

- Inspección regular: Se recomienda revisar el rodillo guía para detectar signos evidentes de desgaste o daños antes y después de cada operación para detectar problemas a tiempo y prolongar la vida útil del producto.

- Instalación adecuada: Durante el proceso de instalación, siga estrictamente el manual de instalación para asegurarse de que todas las uniones estén firmes para evitar afectar el funcionamiento del equipo.

- Notas de mantenimiento: Limpie y lubrique la rueda guía periódicamente para reducir el impacto del polvo y las impurezas en la superficie de fricción y mantenerla funcionando sin problemas.

- Capacitación profesional: Realizamos periódicamente intercambios técnicos y actividades de capacitación, invitamos a los clientes a participar y discutimos conjuntamente métodos de mantenimiento de equipos y sugerencias de mejora de procesos.

Estos consejos prácticos no sólo pueden ayudarle a reducir el riesgo de fallos en las operaciones reales, sino que también brindan sólidas garantías para el mantenimiento a largo plazo del equipo.

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd., fundada en 2011, es un fabricante con amplia experiencia especializado en repuestos para excavadoras y bulldozers, como piezas del tren de rodaje (rodillos inferiores, rodillos superiores, poleas guía, ruedas dentadas, zapatas, cadenas, grupos de orugas), pernos, tuercas, pasadores, bujes y más. Disponemos de una amplia gama de repuestos compatibles con la mayoría de las marcas y modelos del mercado. Entre las marcas compatibles se incluyen Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., abarcando las principales marcas del mercado.

Preguntas frecuentes

Somos un fabricante con amplia experiencia. Nuestra fábrica se encuentra en Xiamei, Quanzhou. Le damos la bienvenida a su visita.

Indíquenos el modelo correcto de la máquina, el número de pieza o algunas especificaciones. Si no son piezas estándar, envíenos los planos.

Generalmente aceptamos T/T; se pueden negociar otros términos.

Por supuesto. Ofrecemos servicio OEM. Si tiene muestras o planos y solicita una gran cantidad, podemos personalizar los productos y ofrecerle soporte técnico profesional.

GFM ha establecido un sistema integral de control de calidad, medio ambiente y seguridad. Cada pieza se somete a rigurosas pruebas y controles de calidad antes de su distribución. Nuestra fábrica cumple con estrictas normas de seguridad y medioambientales durante sus procesos de fabricación.

SOLICITE UNA COTIZACIÓN AHORA

Productos relacionados

- TREN DE ATERRIZAJE

Rueda guía para excavadora Kato HD700

- Rodillo guía

Excavadora de rueda guía delantera Hitachi ZAX870

- TREN DE ATERRIZAJE

Rueda guía New Holland E385C en excavadora

- TREN DE ATERRIZAJE

Rueda guía delantera para bulldozer Komatsu D60 Rueda guía para bulldozer