Fabricantes de zapatas para excavadoras

- Calidad del producto garantizada

- Gran suministro

- Precios competitivos

- La mayoría de marcas y modelos

- Equipo de atención al cliente servicial

- Soporte técnico profesional

Compartir

El zapata de oruga para excavadora Es una placa metálica conectada al eslabón de la vía, dispuesta cuidadosamente a ambos lados de la misma para formar una superficie de contacto firme con el suelo. Sus principales funciones son:

- Proporciona agarre al suelo: ya sea barro, montaña o arena blanda, la placa de cadena es la clave para el avance de la excavadora.

- Dispersa la presión y reduce el hundimiento: la placa de cadena aumenta el área de contacto con el suelo, lo que puede reducir eficazmente la presión de la unidad y aumentar la flotabilidad de la excavadora en terrenos blandos.

- Proteja los eslabones de la cadena y las partes del chasis: la placa de cadena puede reducir el impacto en otros componentes del chasis y extender la vida útil de toda la máquina.

Por lo tanto, elegir una zapata de oruga de alta calidad no solo puede mejorar el rendimiento de la excavadora, sino que también puede ahorrar costos de mantenimiento en la operación a largo plazo.

Las zapatas de oruga GFM buscan lo último en diseño y fabricación. Desde la selección de materiales hasta el procesamiento, cada proceso refleja nuestra constancia en la calidad.

- Material de acero al manganeso o acero de aleación de alta calidad: se utiliza una placa de acero resistente al desgaste de alta resistencia, que tiene una excelente resistencia al impacto y al desgaste, y tiene una vida útil más larga.

- Proceso de fortalecimiento del tratamiento térmico: Hemos mejorado la resistencia y dureza generales de la placa de la cadena a través de los procesos duales de temple y revenido de toda la placa y temple de alta frecuencia de la superficie de la pista, rendimiento especialmente estable en entornos de uso de alta frecuencia.

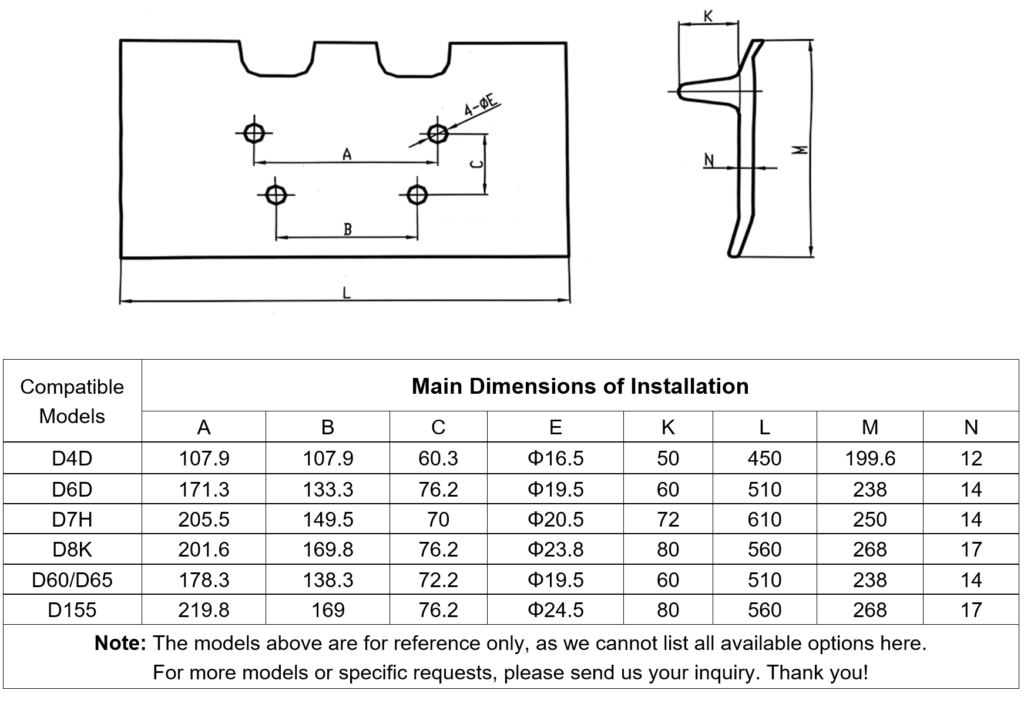

- Diseño de espaciado y espesor de orificios estándar: se adapta a la mayoría de los modelos de excavadoras convencionales del mercado (como Komatsu, Caterpillar, Shantui, etc.) y también admite personalización no estándar.

- Diseño de vía ancha opcional: Proporciona soluciones de placa de cadena ensanchada para escenarios de operación especiales, como pantanos y áreas de aguas altas.

- Tratamiento de revestimiento antioxidante: todas las placas de cadena se tratan con un revestimiento anticorrosión antes de salir de fábrica, adecuado para diversos entornos climáticos extremos.

Descripción del Producto

- Cantidad mínima de pedido: 1 pieza

- Método de pago: Transferencia bancaria

- Marca: GFM

- Condición: Nuevo

- Color: Amarillo, negro o personalizado

- Plazo de entrega: 30 días

- Garantía: 1 año

- Servicio: OEM o ODM

- Lugar de origen: Fujian, China

- Solicitud: Excavadora

- Embalaje: Palet de madera de exportación estándar

Características

- Duradero y de larga duración: Construido con acero de alta calidad para soportar trabajos duros.

- Estabilidad mejorada: Excelente tracción para una operación segura en cualquier terreno.

- Vida útil prolongada: Reduce el desgaste y protege el tren de rodaje.

- Resistente al óxido: Recubierto para un rendimiento confiable en condiciones difíciles.

- Rentable: Reduce los costos de mantenimiento con una durabilidad superior.

- Versátil: Perfecto para rocas, barro, arena o terreno blando.

Presupuesto

Modelos de productos

Proceso de producción

Embalaje y envío

Ventajas de la fábrica

Como un piezas del tren de rodaje de la excavadora GFM, fabricante con más de diez años de experiencia, cuenta con una amplia experiencia en el sector de sistemas de orugas para excavadoras. Hemos construido nuestra propia base de producción, con una superficie de más de 10 000 metros cuadrados, e instalaciones de vanguardia como equipos de forjado importados de Alemania, centros de mecanizado CNC, líneas automáticas de tratamiento térmico y líneas de pulverización anticorrosiva.

Contamos con un proceso completo de control de calidad, desde pruebas de materia prima, control de tolerancia dimensional, análisis metalográfico, hasta pruebas de resistencia previas al ensamblaje, para garantizar que cada placa de cadena cumpla con altos estándares antes de salir de fábrica.

Brindamos servicios personalizados uno a uno para satisfacer sus necesidades especiales.

En GFM, sabemos que cada proyecto tiene necesidades diferentes. Por eso, ofrecemos servicios profesionales y personalizados:

- Personalización de tamaño: según los dibujos o muestras del cliente, se pueden producir con precisión el espaciado de orificios, el ancho, el grosor y otros parámetros requeridos.

- Actualización del material: Proporcione diferentes grados de opciones de acero de aleación para cumplir con escenarios de operación de alta intensidad.

- Personalización del tratamiento de superficies: Se pueden seleccionar métodos de tratamiento como galvanizado, electroforesis y aceite antioxidante según las necesidades.

- Pruebas de lotes pequeños y entregas de lotes: admite pruebas de muestras rápidas, entrega en un plazo de 3 a 7 días; los pedidos por lotes se pueden programar de forma flexible según los requisitos de entrega.

Nuestro equipo técnico le ayudará desde el diseño hasta el producto terminado, hará un seguimiento de todo el proceso y realmente “construirá para los clientes”.

Ya sea que sea un distribuidor de equipos, una unidad de construcción de terminales o un fabricante de mantenimiento de equipos, GFM fabricantes de zapatillas de atletismo Le invitamos a consultarnos con planos y muestras, y le brindaremos asesoramiento profesional y un presupuesto rápido. ¡Elegir GFM significa elegir resistencia y confiabilidad!

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd., fundada en 2011, es un fabricante con amplia experiencia especializado en repuestos para excavadoras y bulldozers, como piezas del tren de rodaje (rodillos inferiores, rodillos superiores, poleas guía, ruedas dentadas, zapatas, cadenas, grupos de orugas), pernos, tuercas, pasadores, bujes y más. Disponemos de una amplia gama de repuestos compatibles con la mayoría de las marcas y modelos del mercado. Entre las marcas compatibles se incluyen Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., abarcando las principales marcas del mercado.

Preguntas frecuentes

Somos un fabricante con amplia experiencia. Nuestra fábrica se encuentra en Xiamei, Quanzhou. Le damos la bienvenida a su visita.

Indíquenos el modelo correcto de la máquina, el número de pieza o algunas especificaciones. Si no son piezas estándar, envíenos los planos.

Generalmente aceptamos T/T; se pueden negociar otros términos.

Por supuesto. Ofrecemos servicio OEM. Si tiene muestras o planos y solicita una gran cantidad, podemos personalizar los productos y ofrecerle soporte técnico profesional.

GFM ha establecido un sistema integral de control de calidad, medio ambiente y seguridad. Cada pieza se somete a rigurosas pruebas y controles de calidad antes de su distribución. Nuestra fábrica cumple con estrictas normas de seguridad y medioambientales durante sus procesos de fabricación.

SOLICITE UNA COTIZACIÓN AHORA

Productos relacionados

- TREN DE ATERRIZAJE

Fabricante de rodillos inferiores para excavadoras CAT E70B

- TREN DE ATERRIZAJE

Proveedor de rodillos de oruga para excavadoras PC40-5 SF

- TREN DE ATERRIZAJE

Conjunto de enlace de cadena para excavadora SY365

- TREN DE ATERRIZAJE

Fábrica de zapatas para excavadoras