Tabla de contenido

Basic Classification and Uses of Excavator Buckets

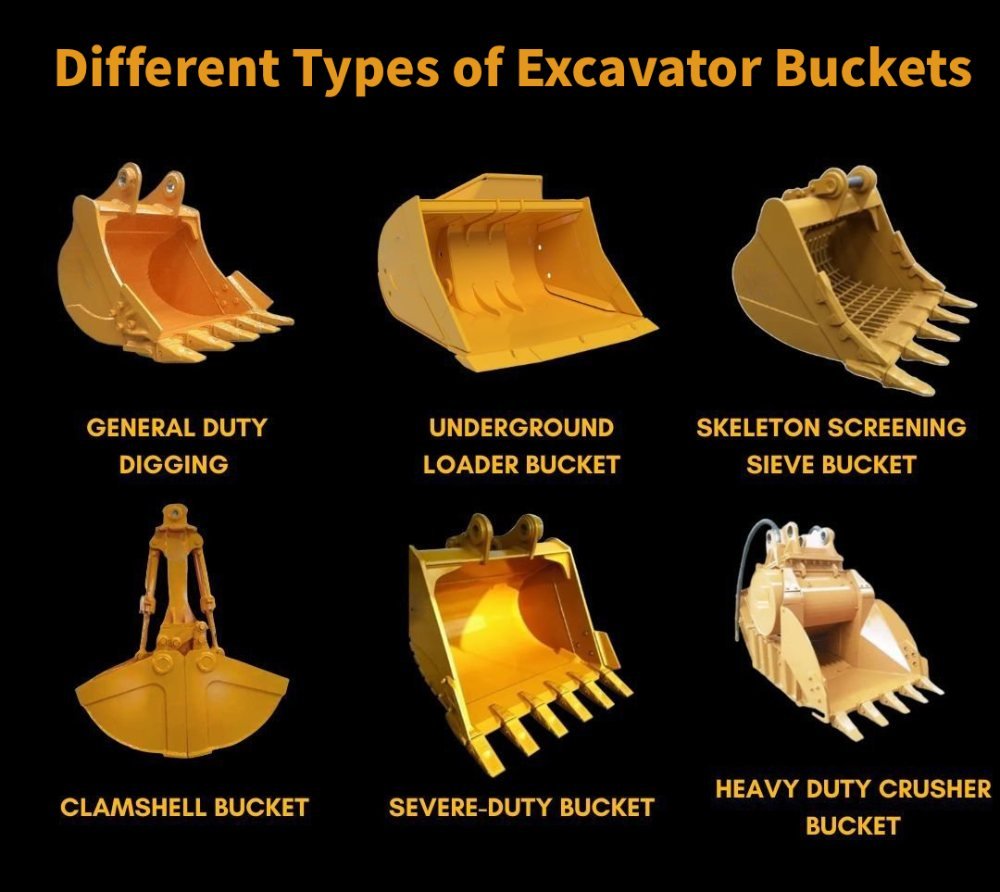

Excavator buckets are one of the most critical components in excavator operations, and their type and use directly affect construction efficiency and costs. According to different operational needs, buckets can be mainly divided into the following types:

- Standard Bucket

- Use: Suitable for excavating regular materials such as soil and gravel.

- Features: Simple structure, moderate capacity, suitable for most construction environments.

- Heavy-Duty Bucket

- Use: Used for high-intensity operations such as hard soil, ore, and construction debris.

- Features: Thickened steel plates, strong impact resistance, high durability.

- Rock Bucket

- Use: Specifically designed for hard rock, ore, and crushed stone.

- Features: Made of high-strength wear-resistant steel, equipped with thickened teeth and side plates, able to withstand high-wear environments.

- Lightweight Bucket

- Use: Suitable for loose soil, mud, or fine excavation work.

- Features: Lightweight, flexible operation, reduces overall machine load, and improves mobility.

In addition, the structural design of the bucket, such as side plate height, tooth arrangement, and reinforcement rib distribution, also affects bucket durability and loading efficiency. When choosing the appropriate bucket, the construction environment, material characteristics, and excavator model should be considered to ensure the bucket is both efficient and durable. For example, in gravel yard operations, a standard bucket can be selected, while in hard rock mining environments, a rock or heavy-duty bucket is recommended to reduce wear and downtime.

Bucket Size and Capacity Selection Tips

The size of the bucket directly determines excavation efficiency and loading capacity, so careful consideration is required when purchasing or selecting a bucket. Key points include:

- Matching Bucket Capacity to Machine Load

- Bucket capacity is usually measured in cubic meters (m³) and should match the excavator’s rated load.

- For example, a 20-ton excavator fits a 1.0–1.2m³ standard bucket, ensuring efficient loading per cycle while avoiding hydraulic system and chassis overload.

- Dimension Analysis

- Bucket width: Affects the amount of material excavated each time; too wide increases resistance, too narrow reduces efficiency.

- Bucket depth and height: Affect loading capacity and digging angle.

- Tooth length and angle: Long teeth are suitable for hard soil and rock, short teeth are suitable for loose materials, improving loading stability.

- Selecting Size Based on Material Characteristics

- Loose soil and gravel: Larger capacity buckets are suitable to improve loading efficiency.

- High-density ore, clay, or concrete debris: Slightly smaller buckets are preferred to reduce resistance and improve operational accuracy.

- Optimizing Operational Efficiency

- By reasonably matching bucket capacity and tooth design, excavation efficiency per cycle can be increased by approximately 10%–15%.

- Proper matching also reduces fuel consumption and equipment wear, improving overall construction cost-effectiveness.

Bucket Material Analysis and Wear Resistance Comparison

Bucket material is a key factor in determining durability and service life. Choosing the right material can significantly reduce maintenance costs and improve operational efficiency. The main points are:

- Common Materials and Features

- High-strength steel (such as Q345B, 70# steel): Good ductility, high strength, suitable for general soil and gravel operations.

- Wear-resistant steel (such as NM360, NM400): High hardness, strong wear resistance, suitable for ore, crushed stone, and high-wear environments. Service life can be 1.5–2 times longer than ordinary steel.

- Composite materials: Combining steel and wear-resistant alloys, ensuring strength while reducing weight, suitable for precise operations and efficient loading.

- Material Selection for Different Parts

- Bucket teeth: Wear-resistant steel or composite materials are more suitable for hard rock operations, extending wear life.

- Side plates and bottom plates: Thickened or hardened treatments enhance impact resistance, reducing machine vibration and deformation risks.

- Wear Resistance Comparison Data

- NM360 wear-resistant steel bucket teeth can support approximately 1,000 hours of wear in continuous rock operations.

- High-strength steel teeth under the same conditions can only support about 400–500 hours.

- Optimizing teeth and bottom plate materials can extend overall bucket service life by more than 30%.

- Material Selection Suggestions

- Loose soil and gravel: High-strength steel buckets are sufficient, with lower costs.

- Hard soil, ore, and crushed stone: Wear-resistant steel or composite buckets are recommended to extend service life and reduce downtime.

- High-load working environments: Thickened bottom plates, reinforcement ribs, and high wear-resistant materials can improve overall impact resistance.

Factors Affecting Bucket Performance

Bucket performance is affected not only by size and material but also by design structure and operating conditions. Understanding these factors helps operators select more suitable buckets and plan operations efficiently. Key factors include:

- Tooth Design

- Pointed teeth: Suitable for hard soil and rock operations, strong penetration.

- Wide teeth: Suitable for loose soil and crushed stone, improving loading stability.

- Composite teeth: Balance penetration and loading stability, suitable for various working conditions.

- Side Plate and Bottom Plate Structure

- Thickened side plates and internal reinforcement ribs improve torsional resistance, reducing bucket deformation under heavy loads.

- Large-capacity buckets can add reinforcement ribs to the bottom plate, increasing overall rigidity and reducing fatigue crack risks.

- Digging Angle and Operation Method

- Different digging angles affect material rebound and hydraulic load, impacting bucket efficiency and durability.

- Proper distribution of loading and unloading actions reduces tooth and bottom plate wear, indirectly affecting performance.

- Working Environment and Load

- High-wear environments (such as ore or crushed stone) accelerate teeth and bottom plate wear.

- High-density materials and overloading increase structural stress, affecting bucket life and performance stability.

- Material and Design Matching

- Material selection for teeth, side plates, and bottom plates directly determines bucket wear resistance and impact resistance.

- In high-load environments, thickened bottom plates and properly arranged reinforcement ribs improve operational stability and wear resistance.

Why Choose GFM as Your Excavator Bucket Partner

GFM is a professional manufacturer of excavator parts since 2011, with over 15 years of manufacturing experience and mature factory production lines, providing high-quality and durable excavator buckets and components worldwide. As an experienced fabricante de cucharones para excavadoras, GFM strictly controls every stage of bucket production, from raw material selection to casting, forging, and heat treatment processes, ensuring that each bucket has excellent wear resistance and impact resistance in high-intensity working environments.

GFM buckets are compatible with multiple mainstream brands, including Komatsu, Hitachi, Caterpillar, Volvo, Kobelco, Doosan, Hyundai, SANY, Liugong, XCMG, Shantui, etc., meeting different models and construction needs. The company is equipped with advanced machinery and quality inspection equipment, capable of efficiently handling bulk orders and providing reliable, durable bucket solutions.

Advantages of choosing GFM include:

- Experiencia profesional en fabricación: 14 years focused on undercarriage and bucket parts, mature processes, reliable technology.

- High-Quality Materials and Processes: Uses premium steel combined with casting, forging, and heat treatment processes to ensure buckets remain durable under high-wear and high-impact conditions.

- Wide Applicability: Designed to suit various working conditions and excavator models, ensuring high efficiency and stability in different construction environments.

- Efficient Delivery and Inventory Assurance: Comprehensive production and storage system ensures timely supply of buckets to support domestic and international project needs.

- Compatible with Mainstream Brands: Broad compatibility with different excavator brands and models, convenient for replacement or upgrades.

With rich industry knowledge, strict quality management, and a professional customer service team, GFM not only provides high-performance buckets but also delivers stable and efficient support for construction projects. Whether for long-term partners or first-time buyers, GFM is committed to being your trusted excavator bucket suppliers.

| Obtenga una cotización rápida y gratuita | Correo electrónico: henry@gfmparts.com | WhatsApp: +86 17705953659 |

Choosing the right excavator bucket is crucial for construction efficiency, operational safety, and equipment longevity. From bucket classification, size and capacity, material characteristics, to performance factors, every aspect affects operational outcomes. Scientific selection and proper matching can improve efficiency while reducing equipment wear and maintenance costs.

As an experienced excavator bucket manufacturer and reliable proveedores de cucharones para excavadoras, GFM is dedicated to providing high-quality, durable, and widely compatible bucket solutions. Whether for routine earthworks or high-intensity rock operations, GFM is your trusted partner. Contact GFM to learn more about professional bucket products and ensure stable and efficient support for your construction projects.