The arrival of spring heralds the beginning of the rainy season. Construction in the rainy season poses a severe test to the performance, safety and life of the excavator. In the face of natural disasters such as river flooding, mountain torrents, and landslides that may be caused by extreme weather, what countermeasures should excavator users take? GFM, a professional fabricante de piezas de excavadora, will systematically analyze the full process solution for rainy season operations to help users reduce downtime losses by more than 30%.

Three deadly threats and response strategies for construction in rainy season

Risk of landslide caused by decreased surface bearing capacity

- Scientific prediction method: Steep slope operations are prohibited when the soil moisture content is >25% when tested with a cone penetrometer

- Emergency treatment plan: Lay a 2.5m×8m steel plate roadbed box to increase the ground pressure ratio

- Real-time monitoring system: Install a GNSS slope displacement monitor (alarm threshold ±3cm/h)

Short circuit failure caused by moisture in the electrical system

Three-level protection system:

- Apply DOW CORNING® 4 insulating silicone grease to the wiring harness connector

- Add an IP67 waterproof box to the controller

- Use 3M™ electronic equipment desiccant after daily operations

Preventive measures for hydraulic oil emulsification

- Install an oil-water separation breathing valve (filtration accuracy ≤3μm)

- Use Mobil DTE 10 Excel™ 46# anti-emulsification hydraulic oil (emulsification time <15min)

- Weekly oil inspection: Replace immediately if moisture content > 0.05%

Standard operating procedures for construction in rainy season

Pre-construction preparation list

Equipment inspection:

- Drain hole of travel motor unblocked (φ6mm needle)

- Drain fuel tank (at least 2 times a day)

- Replacement cycle of wiper rubber strip ≤ 3 months

Environmental assessment toolkit:

- Handheld weather station (real-time monitoring of rainfall > 50mm/h, stop work)

- Groundwater radar scanning underground river

Golden rules for working in the rain

- Travel speed control: ≤ 2km/h (mud mode)

- Working device operating angle: bucket backward tilt ≥ 15° to prevent mud backflow

- Emergency avoidance plan: 30° slope horizontal parking method

Key disposal steps after suspension

- Power-off procedure for the entire vehicle circuit (turn off the main switch first and then remove the key)

- Increase the amount of grease injected into the slewing bearing by 50% (use Shell Gadus S2 V220D2 waterproof grease)

- Radiator backwashing operation (pressure ≤ 0.3MPa)

Special maintenance plan for five core systems in rainy season

Hydraulic system protection

- Filter element replacement cycle shortened by 40%

- Accumulator nitrogen pressure detection (standard value 7±0.5MPa)

- Pilot valve anti-rust treatment (WD-40 Specialist® long-term anti-rust agent)

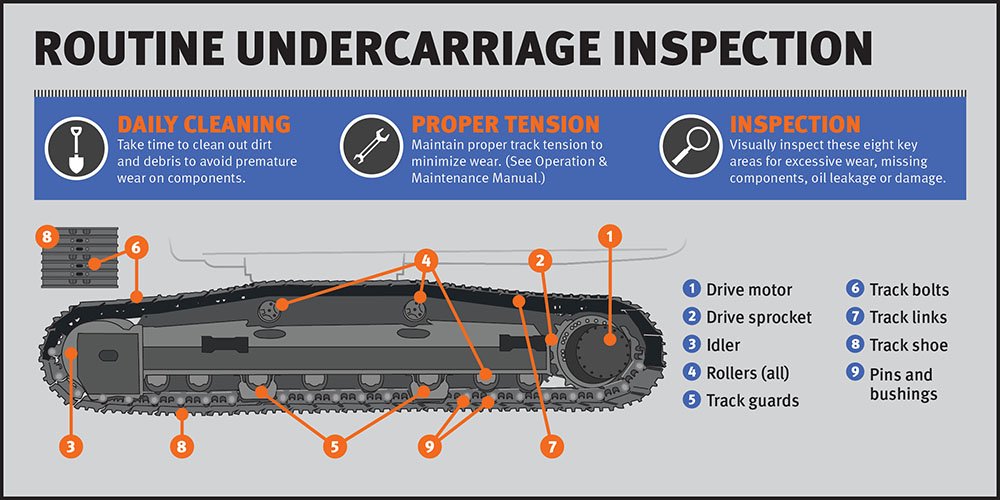

Travel device maintenance

- Track tension adjustment (2-3 grids looser than the standard value in rainy season)

- Guide wheel seal modification (TC type double lip seal ring installed)

- Travel wheel oil filling formula: V=0.785×d²×L×80% (d-aperture, L-wheel width)

Engine waterproof upgrade

- Intake system modification: Install Cyclone® three-stage cyclone pre-filter

- Exhaust bellows inspection standard: Swinging amount>5mm needs to be replaced

- Generator bearing waterproof treatment: NSK 62/22Z anti-mud and water bearing

Rainy season long-term storage specifications

- Parking platform requirements: 15cm thick gravel layer + 5° drainage slope

- Anti-rust treatment plan: Spray Cosmoline RP-342 wax-type protective agent on the exposed metal surface

- Battery maintenance: Disconnect the negative pole and recharge it monthly (voltage ≥ 12.6V)

| Obtenga una cotización rápida y gratuita | Correo electrónico: henry@gfmparts.com | WhatsApp: +86 17705953659 |