Tabla de contenido

Features and Importance of Bucket Teeth

Bucket teeth are one of the most critical components in excavator operations, directly affecting excavation efficiency, equipment lifespan, and construction safety. Whether digging soil, handling gravel, or processing construction debris, bucket teeth perform the functions of breaking, cutting, and bearing loads, acting as the “blade” and “shield” of the excavator bucket.

Basic Functions of Bucket Teeth

Bucket teeth enhance digging capability and improve work efficiency. In soft soil conditions, pointed teeth can penetrate the ground quickly, reducing digging resistance and increasing the excavation volume per hour. In hard rock or construction debris environments, wide teeth or wear-resistant teeth increase contact area and distribute force, protecting the bucket body while improving crushing and loading efficiency. Additionally, bucket teeth reduce direct friction between the bucket and materials, preventing accelerated wear.

Material and Hardness Impact on Lifespan

Materials commonly used for bucket teeth include high-manganese steel, alloy steel, and specially treated surface steel. High-manganese steel offers high toughness and wear resistance, suitable for high-abrasion environments such as mines and gravel yards. Alloy steel balances strength and toughness, suitable for general-purpose operations. Surface-hardened steel, enhanced through quenching and alloy addition, improves wear resistance and impact strength. Under the same conditions, choosing the right material can extend bucket teeth lifespan by over 30%, reducing frequent replacements and downtime costs.

Design Impact on Excavation Efficiency

The shape of bucket teeth directly affects digging efficiency and force distribution. Pointed teeth are ideal for fast soil penetration; wide teeth increase loading capacity, suitable for gravel and loose material; spiral teeth can cut while rotating, improving rock breaking performance. Selecting the appropriate shape ensures durability while significantly enhancing operational efficiency and economic benefits.

Classification of Bucket Teeth

Bucket teeth are classified according to installation methods, shapes, and purposes, with different types suitable for different working conditions.

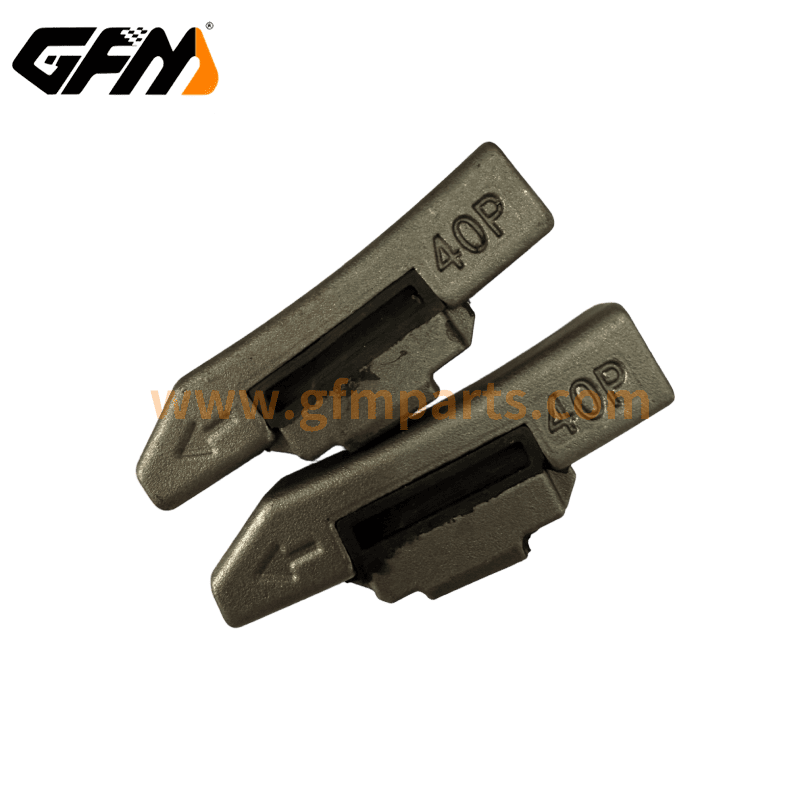

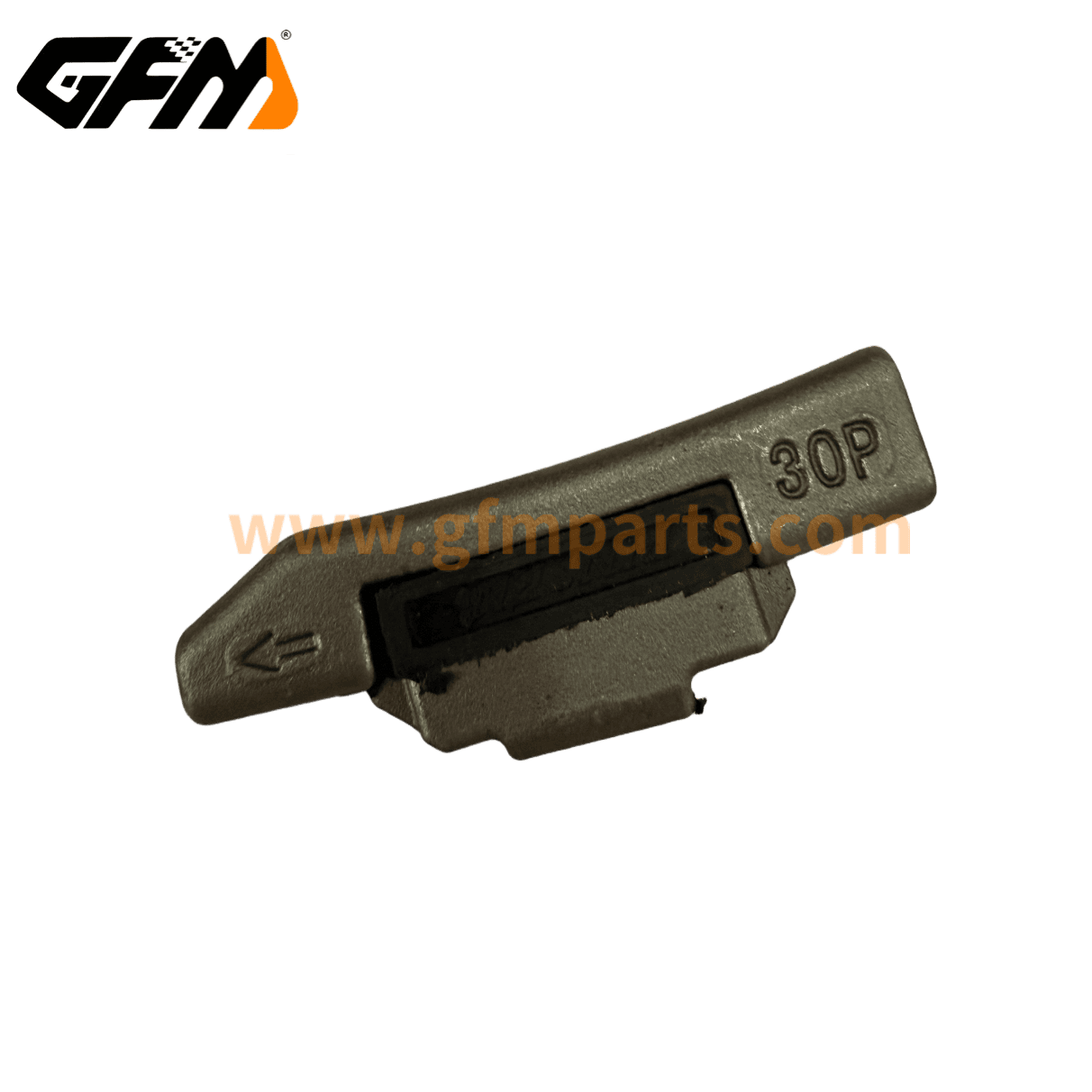

Classification by Installation Method

- Pin-On Teeth: Fixed with pins, easy to install, and quick to replace, suitable for operations requiring frequent maintenance.

- Bolt-On Teeth: Fixed with bolts, stable structure, suitable for heavy excavators and high-intensity operations.

- Weld-On Teeth: Directly welded to the bucket, highly durable, but difficult to replace; typically used in special or long-term projects.

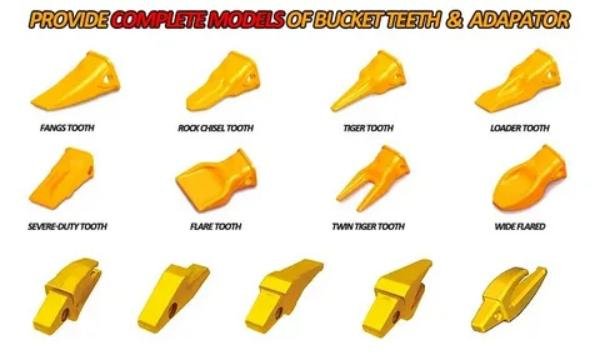

Classification by Shape and Purpose

- Pointed Tooth: Ideal for soft soil and general rock operations, providing excellent penetration.

- Flat Tooth: Suitable for handling gravel, sand, or construction debris, increasing loading efficiency.

- Wear-Resistant Tooth: Surface-treated for high-abrasion environments, such as gravel plants or mining sites.

- Rock Tooth: Designed for hard rocks, thick and impact-resistant, effectively breaking rocks.

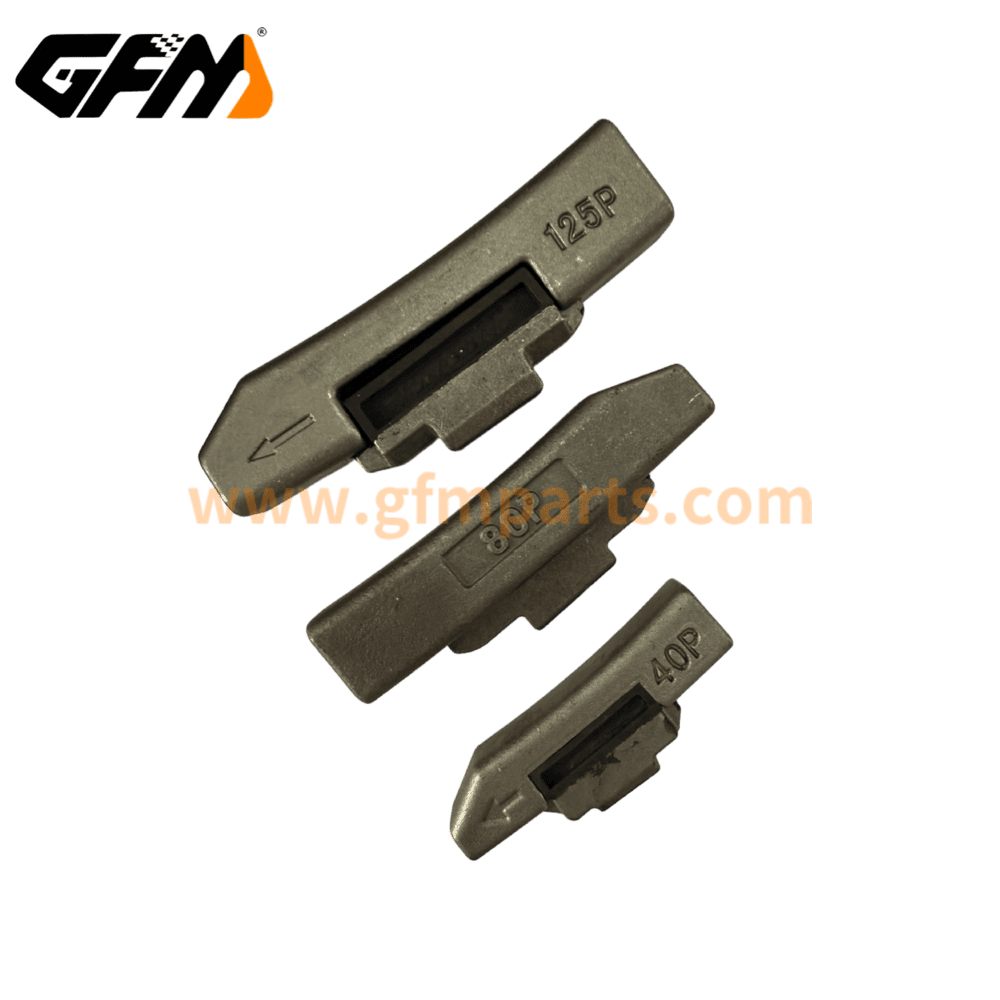

Compatibility with Different Models and Specifications

Excavator models vary, and bucket teeth must match bucket size to ensure safety and efficiency. For example, large excavators often use 500–600 mm teeth, while mid-size models use 400–450 mm teeth. Using incompatible teeth may reduce efficiency or damage the bucket. It is recommended to confirm specifications through reliable fabricantes de dientes de cucharón de excavadora y excavator bucket teeth suppliers.

Materiales y proceso de fabricación

The durability and performance of bucket teeth depend heavily on material selection and manufacturing process.

Selección de materiales

Common materials and characteristics include:

- High-Manganese Steel: Strong wear resistance and toughness, suitable for high-abrasion environments like mines and gravel yards.

- Alloy Steel: Combines toughness and strength, suitable for general engineering operations.

- Surface-Hardened Steel: Enhanced through quenching or alloy addition, with improved wear resistance and impact strength, ideal for heavy-load and high-abrasion conditions.

Proceso de fabricación

- Forja: High-temperature forging produces dense grain structures, increasing strength and toughness.

- Tratamiento térmico: Quenching and tempering adjust hardness and toughness, ensuring durability in high-wear environments.

- Precision Casting: Suitable for complex tooth shapes, smooth surfaces reduce friction and improve operational efficiency.

Quality Assessment Methods

- Prueba de dureza: Ensures the tooth surface meets design standards to prevent rapid wear.

- Wear Testing: Evaluates durability in high-friction environments.

- Impact Strength Testing: Ensures teeth do not fracture under high-impact conditions.

Scientific material selection and precision manufacturing can significantly extend the lifespan of bucket teeth, reducing replacement frequency and operational costs.

Usage and Maintenance Guide

The performance of bucket teeth depends not only on manufacturing quality but also on correct usage and daily maintenance.

Installation and Usage Steps

- Pin-On Teeth: Align the tooth with the slot, insert the pin, and ensure it is fully secured.

- Bolt-On Teeth: Tighten bolts to the specified torque using a torque wrench, avoiding looseness or overtightening.

- Weld-On Teeth: Professional welders should ensure a secure weld with no stress cracks.

Daily Inspection and Maintenance Tips

- Wear Inspection: Regularly measure the tooth tip height and body thickness; replace teeth that exceed wear limits.

- Rotational Use: Rotate symmetric teeth to extend overall lifespan.

- Reemplazo oportuno: Replace long-used teeth even if not fully worn to maintain efficiency and safety.

Tips to Extend Lifespan

- Avoid empty-load operations to reduce impact on teeth.

- Maintain proper digging angles to reduce friction and wear.

- For high-abrasion environments, use wear-resistant or high-manganese steel teeth in advance.

Problemas comunes y soluciones

Common issues with bucket teeth include wear, breakage, and improper installation. Scientific analysis and timely handling can effectively prevent or solve these problems.

Common Wear Types

- Tip Wear: Concentrated force flattens the tip, reducing penetration ability.

- Side Wear: Continuous friction thins the sides, reducing stability.

- Breakage: High impact or improper operation can fracture teeth, requiring immediate replacement.

Causes

- Unsuitable Material: Ordinary steel wears quickly in hard environments.

- Incorrect Installation: Loose bolts or pins may cause misalignment or fractures.

- Operación incorrecta: Excessive impact, empty-load operation, or incorrect angles accelerate wear and breakage.

Solutions

- Choose high-quality bucket teeth through reliable excavator bucket teeth manufacturers and excavator bucket teeth suppliers.

- Install according to standards and inspect regularly.

- Replace worn or damaged teeth promptly to maintain operational efficiency.

Case Reference

In a mining operation, heat-treated high-manganese steel teeth reduced wear by approximately 35% compared to ordinary cast steel teeth, improving operational efficiency by 12%. This demonstrates the importance of material selection, proper installation, and regular maintenance.

| Obtenga una cotización rápida y gratuita | Correo electrónico: henry@gfmparts.com | WhatsApp: +86 17705953659 |

As a critical component of excavator operations, bucket teeth directly affect construction efficiency and equipment lifespan. By selecting the appropriate type, material, and specification, and following scientific usage and maintenance methods, operational efficiency can be improved, and replacement costs reduced. Choosing reliable excavator bucket teeth manufacturers and excavator bucket teeth suppliers ensures product quality and after-sales support, providing stable support for construction operations. Proper management extends the lifespan of bucket teeth, achieving safe, efficient, and cost-effective work.