Fabricante de rodillos de oruga para miniexcavadoras

- Calidad del producto garantizada

- Gran oferta

- Precios competitivos

- La mayoría de las marcas y modelos

- Equipo de atención al cliente servicial

- Soporte técnico profesional

Compartir

Como profesional track roller manufacturer, we focus on the research and development and manufacturing of small excavator track rollers, and are committed to providing high-performance, durable and environmentally friendly product solutions for the construction machinery industry.

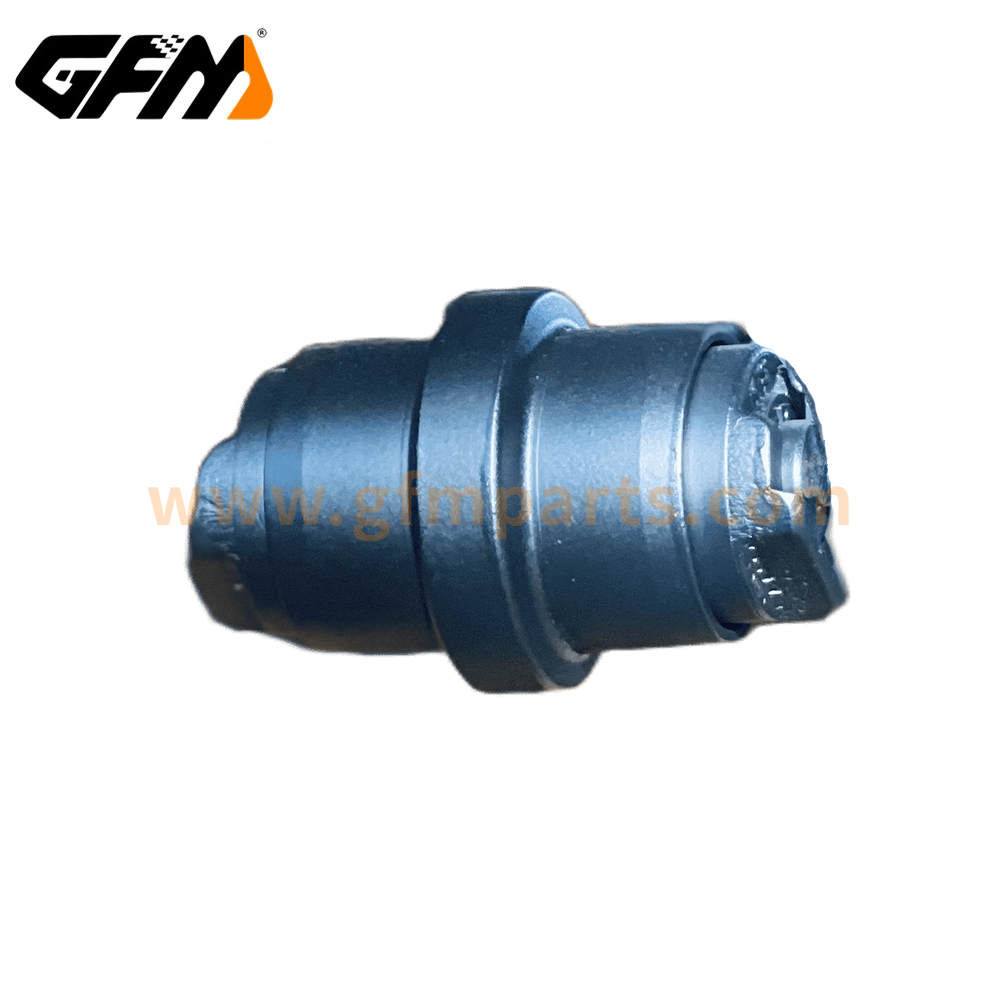

GFM Rodillo de oruga para miniexcavadora is designed with internationally leading materials and advanced processes, and are tailored for small excavators under high load and long-term operation environments. Our products have undergone rigorous laboratory and field testing to ensure that they can stably exert super strong load-bearing capacity and wear resistance under various working conditions such as municipal engineering, construction, and mining. They are an ideal choice for customers to improve equipment stability and extend the life of the entire machine.

Product Features and Advantages

Material innovation and protection technology

- High-quality wear-resistant materials: high-strength alloy steel and special metallurgical technology are used to improve the impact resistance and wear resistance of the track rollers from the source, and excellent performance can be maintained even under extreme working conditions.

- Advanced surface treatment technology: through high-temperature heat treatment, cold plating and anti-corrosion coating processes, corrosion and fatigue damage can be effectively prevented, ensuring long-term stable operation of the product and reducing subsequent maintenance costs.

Precision manufacturing and intelligent production

- CNC precision machining: Introduce multi-axis CNC machine tools to achieve high-precision cutting and processing, ensuring that each track roller meets strict design dimensions and quality standards.

- Intelligent detection system: Laser measurement and three-coordinate detection technology are used throughout the process to monitor the processing process in real time, prevent defective products from entering the market, and ensure product consistency and reliability.

Scientific design and strict verification

- Optimized structural design: Use advanced CAD/FEA technology to perform mechanical simulation and optimization design on the product, fundamentally improving the load-bearing capacity and wear resistance of the track roller.

- Multiple working condition testing: The product has been verified by multiple experiments such as high temperature, high pressure, and fatigue resistance, strictly complies with international certification standards, and provides customers with reliable quality assurance.

Performance advantages and application value

- Ultra-high load-bearing capacity: The combination of optimized design and high-strength materials enables the product to have excellent load-bearing performance and can adapt to the high-intensity operation of small excavators in heavy-load working environments.

- Long-lasting and durable: Multiple protection technologies effectively extend the service life of the product, reduce the frequency of equipment maintenance, and save operating costs for customers.

- Stability guarantee: precise balance design and strict manufacturing process ensure that the product runs smoothly in long-term continuous work and reduce the risk of failure.

Descripción del Producto

- Cantidad mínima de pedido: 1 pieza

- Método de pago: Transferencia bancaria

- Marca: GFM

- Condición: Nuevo

- Color: Amarillo, negro o personalizado

- Plazo de entrega: 30 días

- Garantía: 1 año

- Servicio: OEM o ODM

- Lugar de origen: Fujian, China

- Solicitud: Excavador

- Embalaje: Palet de madera de exportación estándar

Características

- De primera calidad Materiales:Fabricado con acero resistente al desgaste de alta calidad para garantizar una vida útil más larga y un rendimiento constante.

- Sellado y lubricado:Diseñado con un sistema sellado que mantiene los rodillos lubricados, reduce la fricción y evita la entrada de suciedad o agua.

- Funcionamiento suave y estableDiseñado con precisión para un movimiento equilibrado, mejorando la eficiencia de su maquinaria.

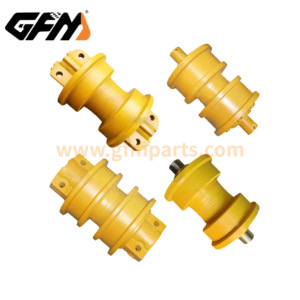

- Se adapta a varios modelos:Se ofrece en diseños de brida simple, brida doble y brida central para adaptarse a una amplia gama de excavadoras y bulldozers.

- Dureza comprobada:Probado para manejar cargas pesadas y funcionar eficazmente en entornos difíciles, lo que garantiza un tiempo de inactividad mínimo.

En GFM Factory, nos comprometemos a ofrecer componentes de alta calidad que mejoran la eficiencia y la durabilidad de su equipo. Nuestros rodillos guía están diseñados para mantener su maquinaria funcionando al máximo rendimiento, reduciendo el tiempo de inactividad y los costos de mantenimiento.

Para más información o consultas sobre modelos específicos, contáctenos. GFM Factory: ¡Su proveedor confiable de repuestos!

Presupuesto

Modelos de productos

Proceso de producción

Embalaje y envío

Ventajas de la fábrica

GFM fábrica de rodillos de oruga is a well-known high-standard production base in the industry, with advanced production lines and a complete quality control system. As a professional fabricante de piezas de excavadora, we insist that each product must pass rigorous testing to ensure that it meets international quality standards. We have rich manufacturing experience and can provide customized production services according to customer needs to meet different market needs.

Advanced production equipment and automated management

- World-class equipment: The factory is equipped with modern CNC machining centers and fully automated production lines to achieve efficient and accurate mass production.

- Intelligent management system: Introduce intelligent systems to monitor the production process throughout the process to ensure product quality and delivery timeliness.

Strict quality management system

- Full process quality inspection: from raw material procurement, production and processing to finished product testing, each process implements strict quality control, and the products pass international standard certification.

- Professional testing team: We have experienced quality inspection experts and use advanced testing equipment to ensure that each batch of products meets international high standards.

Strong R&D and technical support

- Professional R&D team: The R&D team composed of senior engineers and technical experts continues to carry out technological innovation and product upgrades, and constantly introduces new materials and new processes.

- Scientific research cooperation: We have established strategic cooperation relationships with many well-known scientific research institutions and technical institutions at home and abroad to jointly promote the development and progress of supporting wheel technology.

Contáctenos

If you are looking for high-quality track rollers for mini excavator, GFM excavator accessories will be your best choice. Welcome to visit our official website or call the customer service hotline for more product details and technical support information. We look forward to working with you to create a better future!

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd., fundada en 2011, es un fabricante con amplia experiencia especializado en repuestos para excavadoras y bulldozers, como piezas del tren de rodaje (rodillos inferiores, rodillos superiores, poleas guía, ruedas dentadas, zapatas, cadenas, grupos de orugas), pernos, tuercas, pasadores, bujes y más. Disponemos de una amplia gama de repuestos compatibles con la mayoría de las marcas y modelos del mercado. Entre las marcas compatibles se incluyen Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., abarcando las principales marcas del mercado.

Preguntas frecuentes

Somos un fabricante con amplia experiencia. Nuestra fábrica se encuentra en Xiamei, Quanzhou. Le damos la bienvenida a su visita.

Indíquenos el modelo correcto de la máquina, el número de pieza o algunas especificaciones. Si no son piezas estándar, envíenos los planos.

Generalmente aceptamos T/T; se pueden negociar otros términos.

Por supuesto. Ofrecemos servicio OEM. Si tiene muestras o planos y solicita una gran cantidad, podemos personalizar los productos y ofrecerle soporte técnico profesional.

GFM ha establecido un sistema integral de control de calidad, medio ambiente y seguridad. Cada pieza se somete a rigurosas pruebas y controles de calidad antes de su distribución. Nuestra fábrica cumple con estrictas normas de seguridad y medioambientales durante sus procesos de fabricación.

SOLICITE UNA COTIZACIÓN AHORA

Productos relacionados

- Rodillo de oruga

Fabricante de rodillos inferiores para excavadoras CAT E70B

- Rodillo de oruga

Rodillo de oruga Bobcat X320 para miniexcavadoras

- Rodillo de oruga

La mejor fábrica de rodillos inferiores para excavadoras

- TREN DE ATERRIZAJE

Fabricante de grupos de orugas para excavadoras