Bulldozers are indispensable heavy machinery in engineering construction, and their chassis system plays a vital role in the working efficiency and stability of bulldozers. As the “skeleton” of the bulldozer, the chassis contains multiple key components that work together to ensure the smooth operation of the bulldozer.

Are you looking for top parts for your bulldozer at the best prices? You’ve come to the right place. We are committed to providing exceptional products that offer the best value to our customers. Your satisfaction is our motivation. Email henry@gfmparts.com hoje mesmo e um de nossos especialistas em material rodante de escavadeira ficará feliz em ajudar você.

| Obtenha um orçamento rápido e gratuito | E-mail: henry@gfmparts.com | Whatsapp: +86 17705953659 |

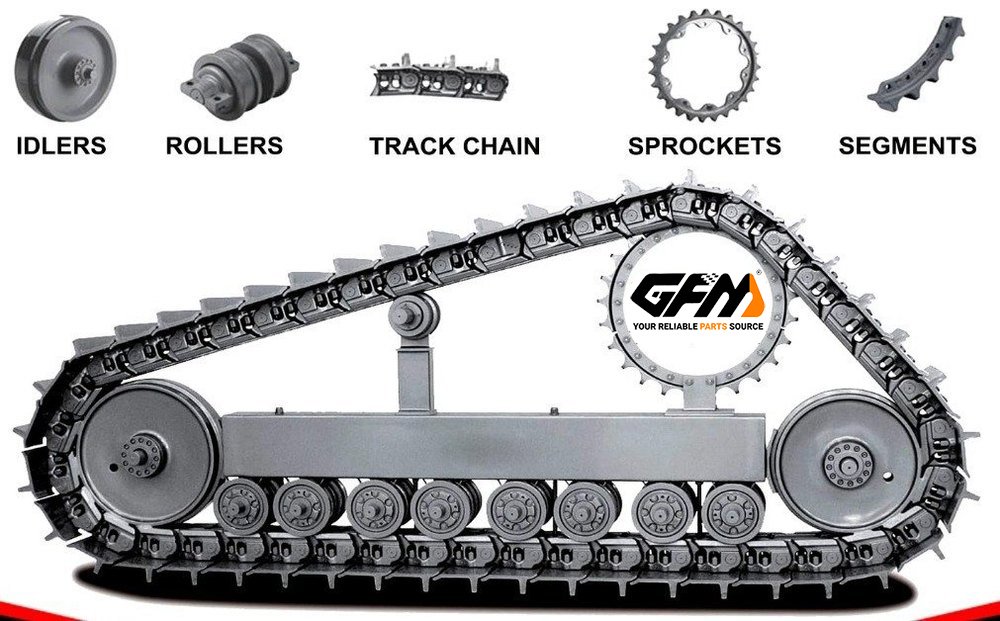

GFM Bulldozer Undercarriage Supplier

O dozer undercarriage part is an important guarantee of bulldozer performance, and its stability directly affects the working efficiency and safety of the machine. Understanding the composition principle of the undercarriage, timely discovering and solving common faults, and regular maintenance are the key to ensure the long-term stable operation of the bulldozer. If you need to purchase bulldozer undercarriage parts or need more professional advice, please contact us. We provide high-quality bulldozer accessories and provide you with comprehensive technical support.

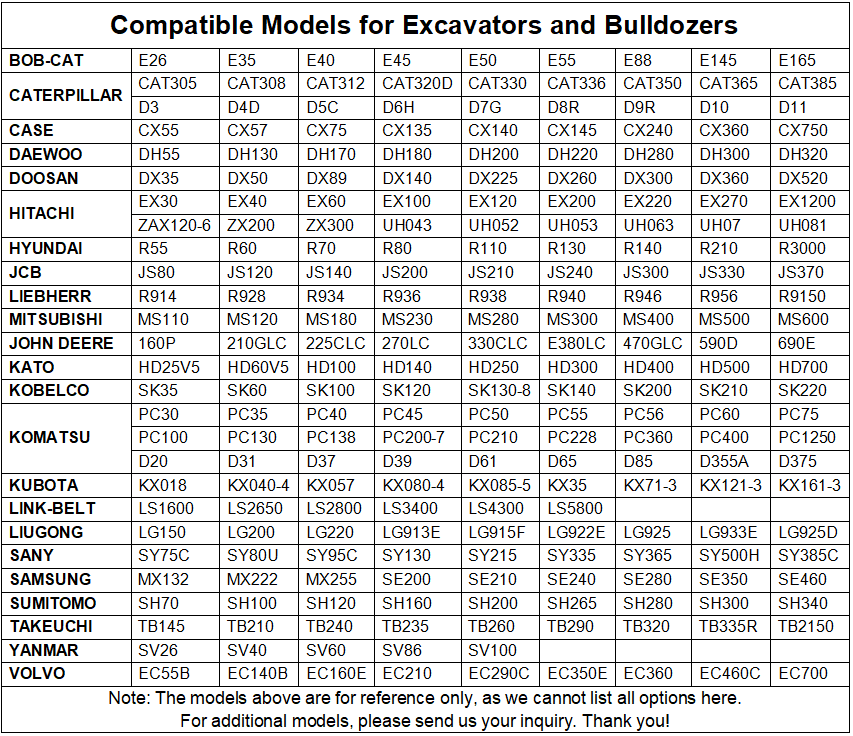

GFM specializes in providing high-performance bulldozer undercarriage parts for global customers to ensure long-term operation of equipment in harsh environments. Each product undergoes quality assurance inspection and testing to meet and exceed industry benchmarks. Our wide range of chassis parts will definitely get your excavator back on site in a short time.

Grupo de trilhas

Link da trilha

Sapata de corrida

Rolo de transporte

Rolo de esteira

Roda dentada

Líder da trilha

Caçambas para escavadeiras

Dentes de balde

Cilindro Hidráulico

Pin & Bush

Parafuso e Porca

With 14 years of experience, we understand your equipment needs and can help you get the right crawler dozer undercarriage parts for any model and make.

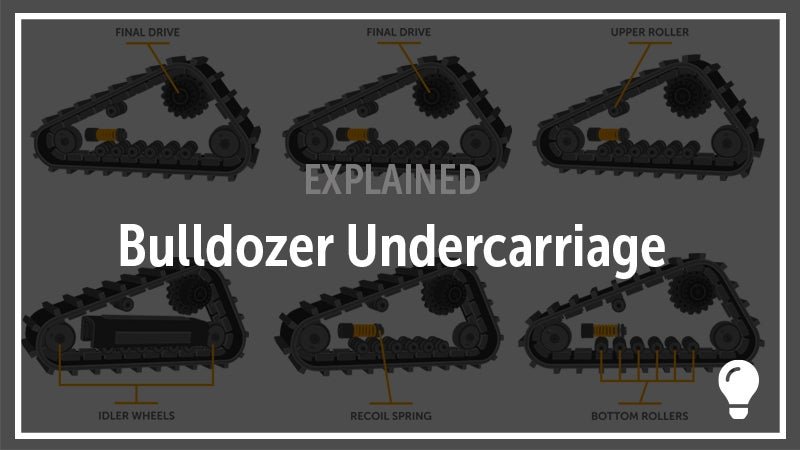

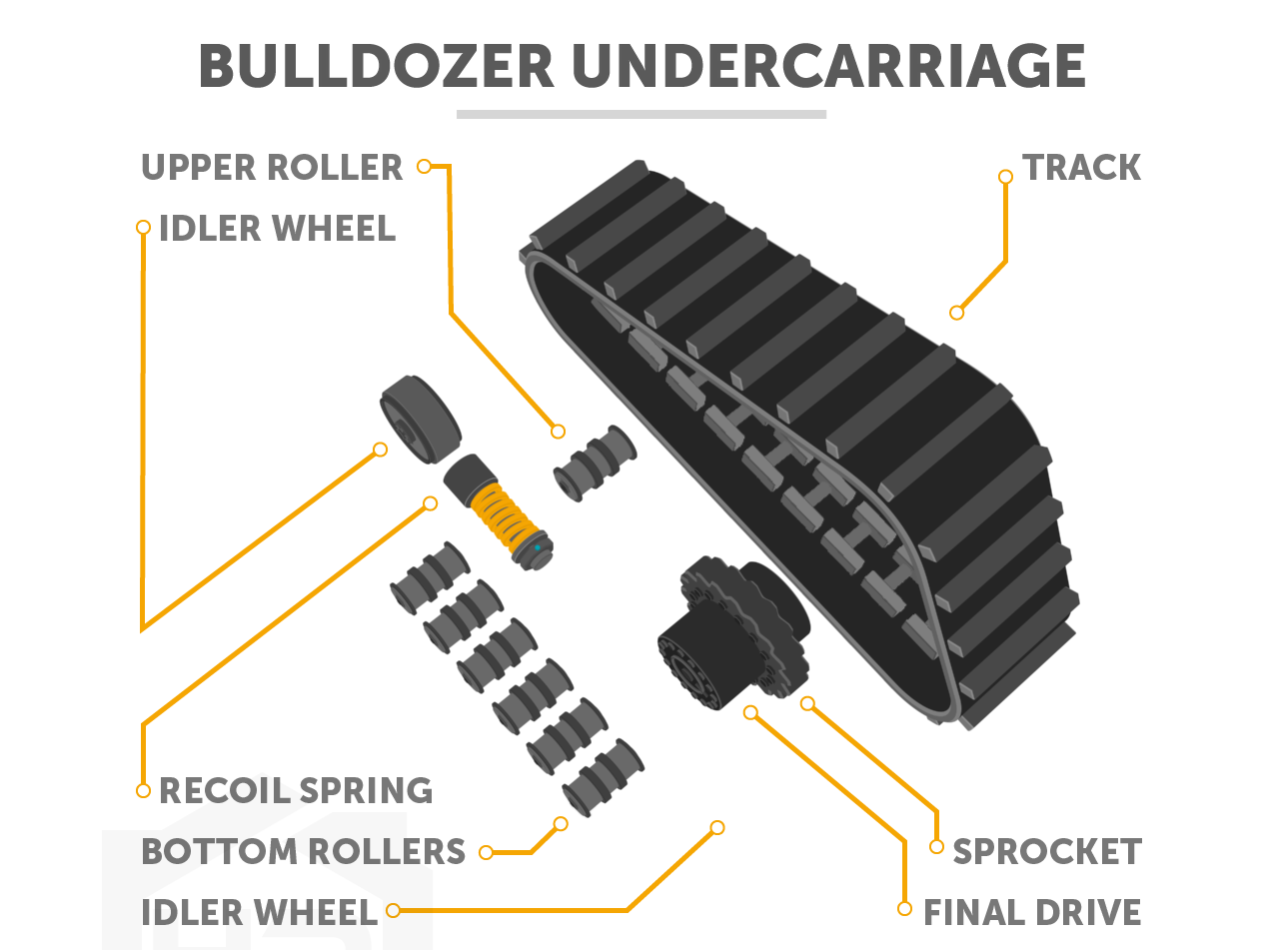

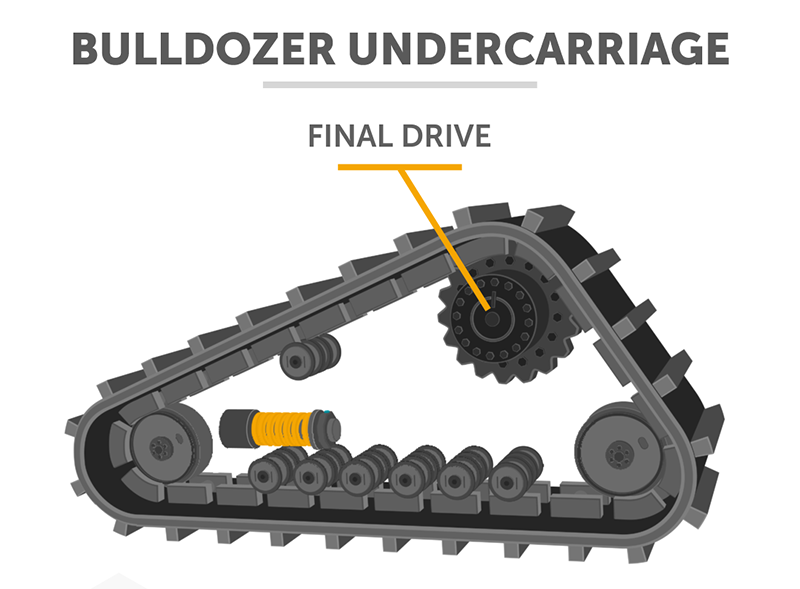

Composition and principle of bulldozer undercarriage

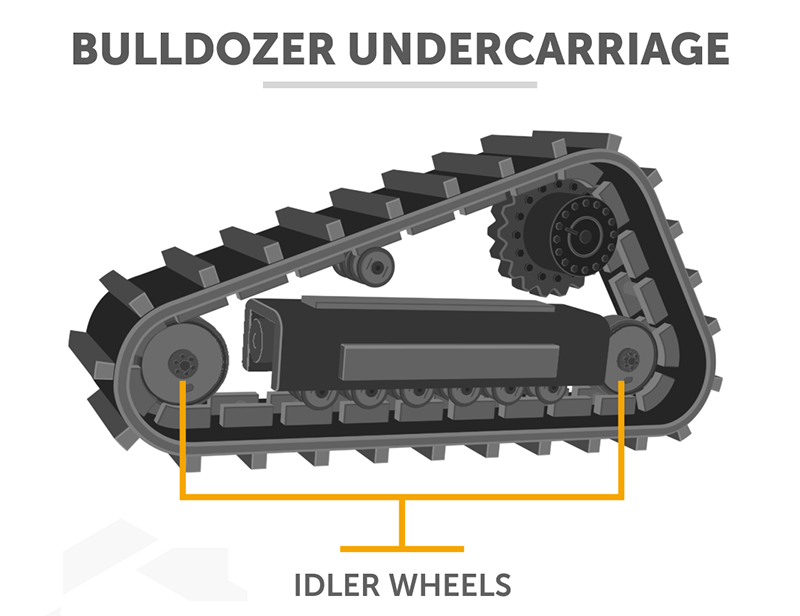

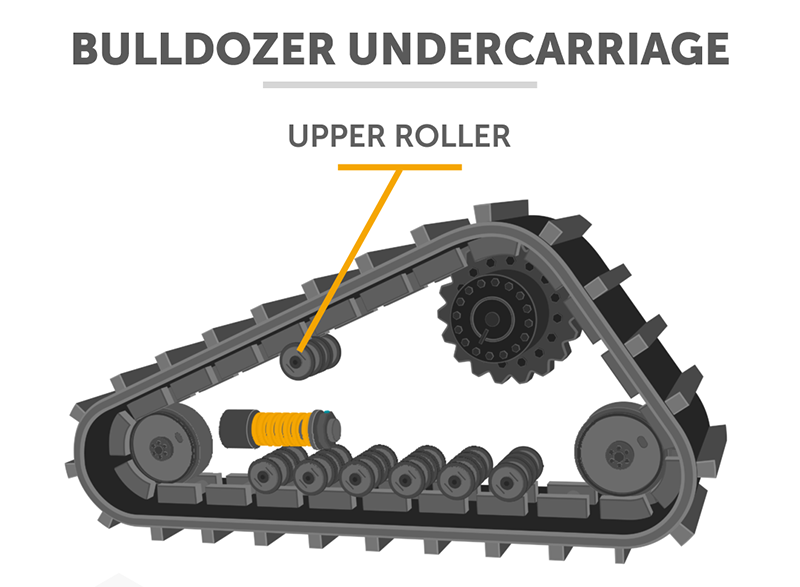

The structure of bulldozer undercarriage is very complex, mainly composed of the following core components:

- Track assembly: The track is one of the most important parts of the bulldozer. It is responsible for dispersing the weight of the machine and improving the traction and stability of the bulldozer.

- Drive wheel and guide wheel: The drive wheel drives the track through the power of the engine, while the guide wheel is used to control the movement direction of the track.

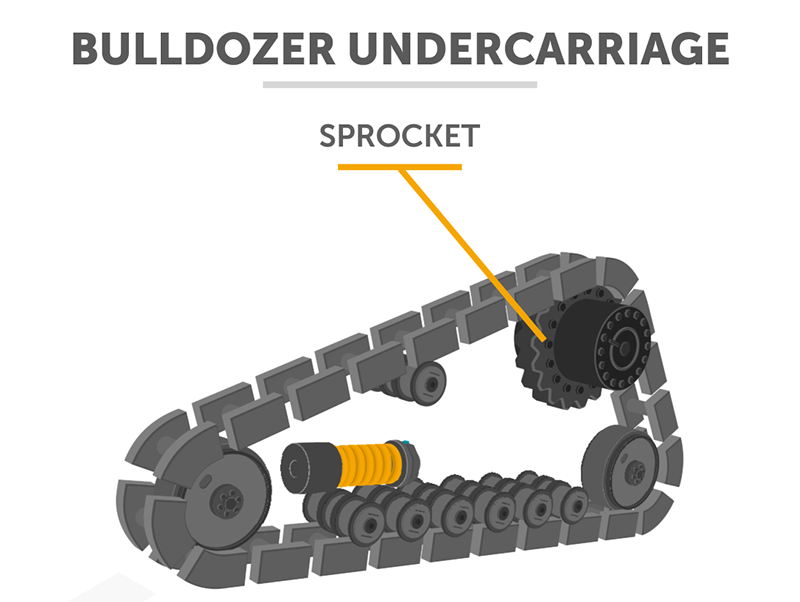

- Sprocket wheel: The contact part between the sprocket wheel and the track plays a role in maintaining the position of the track.

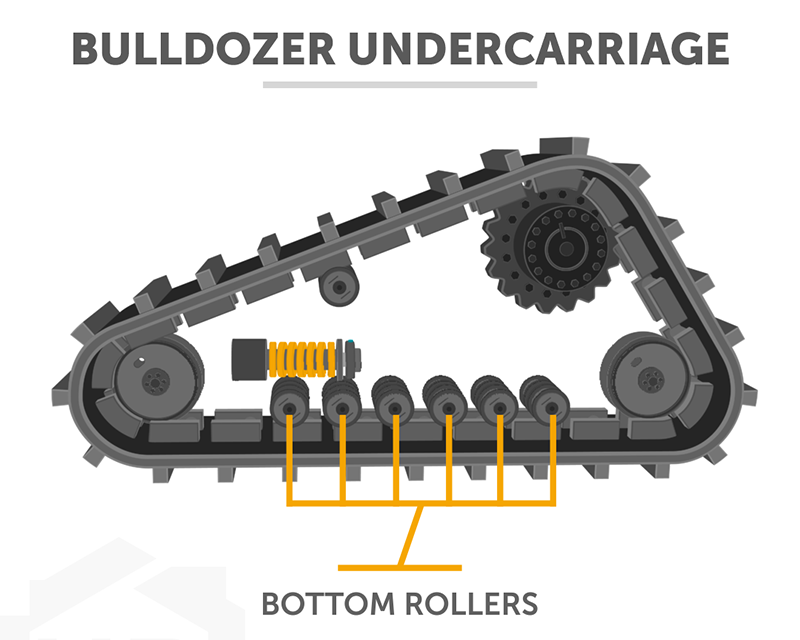

- Support chain plate: The support chain plate ensures the smooth operation of the track and is the support structure of the track.

- Sistema de suspensão: The suspension system can reduce chassis vibration and improve the comfort and stability of the machine.

The working principle of the bulldozer undercarriage is based on the interaction between its components. The track slides on the ground through the cooperation of the drive wheel and the sprocket wheel to keep the bulldozer stable and effectively distribute the weight of the machine to ensure that the bulldozer can operate smoothly on different types of ground.

Why do bulldozers need tracks?

Bulldozers use tracks instead of wheels mainly to improve their traction and passability on uneven, muddy, sandy or soft ground. The design of the tracks can disperse the weight of the bulldozer over a large area to prevent the wheels from sinking into soft ground or mud. Therefore, the tracks not only enhance the stability of the bulldozer, but also improve the bulldozer’s ability to operate in complex terrain. Especially in harsh environments such as mountainous areas, deserts or wetlands, the track assembly is the key to the bulldozer’s efficient operation.

Common faults of bulldozer undercarriage

Although the bulldozer undercarriage is designed to be sturdy, due to long-term and high-intensity use, some common faults may still occur in the undercarriage parts, mainly including:

- Excessive wear of the track: The track is one of the most easily worn parts. Long-term use will cause damage to the track surface and even breakage.

- Improper track tension: Too much or too little track tension will affect the operating performance of the bulldozer. Excessive tension will increase the burden on the drive system, while too little tension may cause the track to fall off or slip.

- Damage to the drive wheel or carrier sprocket: Due to the huge mechanical pressure, the drive wheel and carrier sprocket sometimes crack or wear, resulting in unstable track movement.

- Failure of the suspension system: The suspension system of the bulldozer is used to absorb the impact of the ground and prevent the machine from vibrating too much. When the suspension system fails, the bulldozer may experience severe vibration or unstable operation.

If these common faults are not repaired or replaced in time, they may affect the operating efficiency of the bulldozer or even cause greater damage.

Daily maintenance of the bulldozer undercarriage

In order to ensure the long-term stable operation of the bulldozer chassis, the following are some daily maintenance suggestions:

- Check the track regularly: Make sure there are no obvious cracks or damage on the surface of the track. If severe wear is found, it should be replaced in time. Check the track tension regularly to maintain proper tension and avoid being too loose or too tight.

- Lubricate the drive wheel and carrier sprocket: Regularly lubricate the drive wheel, carrier sprocket and other moving parts to reduce friction and extend the service life of the parts.

- Clean undercarriage parts: Especially when working in harsh environments, the bulldozer chassis is prone to accumulate dirt, sand and other debris, which affects the normal operation of the components. Clean the chassis components regularly to prevent debris from damaging the machine.

- Check the suspension system: Check the working condition of the suspension system regularly to ensure its good shock absorption effect. If it is loose or faulty, repair or replace it in time.

- Check the sprockets and chain plates regularly: The sprockets and support chains play a supporting role in the bulldozer chassis. Make sure they are not loose or worn. Check and reinforce these components regularly.

Vantagens das peças de material rodante GFM

- Alta durabilidade: All GFM undercarriage parts are made of top-quality materials and advanced manufacturing processes, ensuring that they have a long service life and low maintenance frequency.

- Adaptação precisa: Oferecemos uma ampla gama de especificações de componentes de chassi que podem corresponder com precisão a vários modelos de escavadeiras e miniescavadeiras para garantir o encaixe perfeito do produto.

- Forte resistência ao impacto: GFM undercarriage parts are designed to cope with extreme working conditions, ensuring that the equipment can still operate stably in harsh environments.

- Serviço de personalização do cliente: Oferecemos aos clientes serviços personalizados e fornecemos soluções de chassis feitas sob medida, de acordo com diferentes requisitos de uso e ambientes de trabalho.

Fornecer aos clientes suporte completo

A GFM não só fornece alta qualidade trem de pouso de escavadeira, but also provides customers with comprehensive technical support. Our professional team will provide you with accurate installation guidance, maintenance recommendations and regular product inspection services to ensure that your bulldozer is always in the best working condition.

Inspeção diária de peças do chassi do trator e da escavadeira

Montagem de trilhos

- Verifique a estanqueidade da pista: Esteiras muito apertadas ou muito frouxas afetarão a estabilidade e a eficiência operacional do equipamento. Esteiras muito apertadas aumentarão o consumo de combustível, enquanto esteiras muito frouxas podem causar deslizamento ou desgaste excessivo.

- Verifique o desgaste da pista: Verifique se a esteira está rachada, quebrada ou excessivamente desgastada. A substituição oportuna de esteiras muito desgastadas pode evitar maiores danos a outros componentes.

- Verifique a roda guia da esteira: se a roda-guia está solta ou desgastada. O bom estado da roda-guia pode guiar eficazmente o movimento da esteira e evitar que ela fique desalinhada.

Sistema de acionamento

- Verifique a roda motriz: O desgaste excessivo da roda motriz pode causar má transmissão de potência da esteira e afetar a eficiência operacional. Verifique se a engrenagem da roda motriz está desgastada ou trincada para garantir seu funcionamento normal.

- Verifique a corrente e a placa da corrente: A corrente é uma peça importante que conecta a roda motriz à esteira. Verifique se a corrente está frouxa, corroída ou desgastada para garantir seu aperto e durabilidade.

Sistema de suspensão

- Verifique as molas e amortecedores: O sistema de suspensão de tratores de esteira e escavadeiras garante a estabilidade do chassi. Verifique se as molas estão deformadas, quebradas ou perdem elasticidade para evitar que a estabilidade de todo o veículo seja reduzida devido a falhas no sistema de suspensão.

- Verifique o sistema hidráulico: se o sistema hidráulico está vazando ou danificado e se o nível do óleo hidráulico está normal. A falha do sistema hidráulico afetará diretamente o movimento e o desempenho operacional do chassi.

Peças de conexão da cabine e do chassi

- Verifique as peças de conexão entre o chassi e a cabine: Verifique se os parafusos de fixação entre o chassi e a cabine estão soltos e se as peças de conexão estão rachadas. Peças de conexão soltas podem causar instabilidade do chassi ou vibração excessiva da cabine.

Sistema de lubrificação

- Verifique a lubrificação do chassi: Adicione óleo lubrificante regularmente às partes móveis do chassi para garantir que o atrito entre elas seja minimizado. Verifique se o óleo lubrificante está em boas condições e se há vazamentos.

Equipment undercarriage maintenance tips

- Evite carga excessiva: A sobrecarga fará com que o chassi suporte pressão excessiva e acelere o desgaste. Certifique-se de que o equipamento opere dentro da faixa de carga projetada para prolongar a vida útil do chassi.

- Operação razoável: Opere o equipamento suavemente, evite frenagens repentinas, acelerações repentinas e outras ações violentas e reduza a carga de impacto no chassi e outros componentes.

- Inspeção regular: Além da inspeção e manutenção diárias, inspeções abrangentes são realizadas em intervalos regulares, incluindo inspeção de componentes do chassi, testes de pressão de sistemas hidráulicos, etc., para garantir que o equipamento esteja em boas condições.