Pino de dente de caçamba e retentor CAT E330

- Qualidade do produto garantida

- Grande oferta

- Preços competitivos

- A maioria das marcas e modelos

- Equipe de Atendimento ao Cliente Útil

- Suporte técnico profissional

Compartilhar

CAT E330 excavator is an industry-recognized efficient construction machinery, and GFM PARTS’ excavator bucket tooth pin is a high-quality component tailored for this excavator. Our bucket tooth pin is made of high-strength steel and is made through a strict process. Every detail reflects the factory’s rich experience and technical strength. The product design focuses on ease of use and durability to ensure that customers can use it stably during construction, reduce maintenance costs, and improve efficiency. Whether it is daily maintenance or emergency repairs, you can rest assured to choose our bucket tooth pin products and experience high-quality protection.

Our CAT E330 pino de dente de escavadeira not only meets the original factory standards, but also has been optimized in many aspects:

- Strong wear resistance: Made of high-quality alloy steel, high-temperature heat treatment, wear-resistant and durable

- Convenient installation: Reasonable design, can be quickly replaced and installed, reducing construction downtime

- Safe and reliable: Strict quality monitoring and multiple tests to ensure the service life of each part

- High adaptability: Suitable for different working conditions, whether it is rock mining or municipal engineering, it can play a stable role

These technical advantages make our products very competitive in the market. Each bucket tooth pin represents the factory’s adherence to quality and reputation, and provides customers with practical solutions.

Descrição do produto

- Matéria-prima: 40CR

- Quantidade mínima: 1 PC

- Método de pagamento: T/T

- Marca: GFM

- Doença: Novo

- Cor: Amarelo, Preto ou Personalizado

- Tempo de espera: 30 dias

- Garantia: 1 ano

- Serviço: OEM ou ODM

- Local de origem: Fujian, China

- Aplicativo: Escavadora

- Embalagem: Palete de madeira padrão para exportação

Projetados para durabilidade e precisão, os pinos de dentes de caçamba GFM garantem máxima eficiência para suas tarefas pesadas.

Características

- Material durável: Aço de liga premium para extrema resistência ao desgaste.

- Ajuste perfeito: Projetado com precisão para reduzir o desgaste e melhorar a estabilidade.

- Tratado termicamente: Dureza aprimorada para maior vida útil.

- Resistente à ferrugem: Revestimento anticorrosivo para desempenho duradouro.

- Fácil instalação: Substituição rápida e sem complicações.

Escolha a GFM para pinos de dentes de caçamba confiáveis e econômicos, compatíveis com uma ampla variedade de escavadeiras.

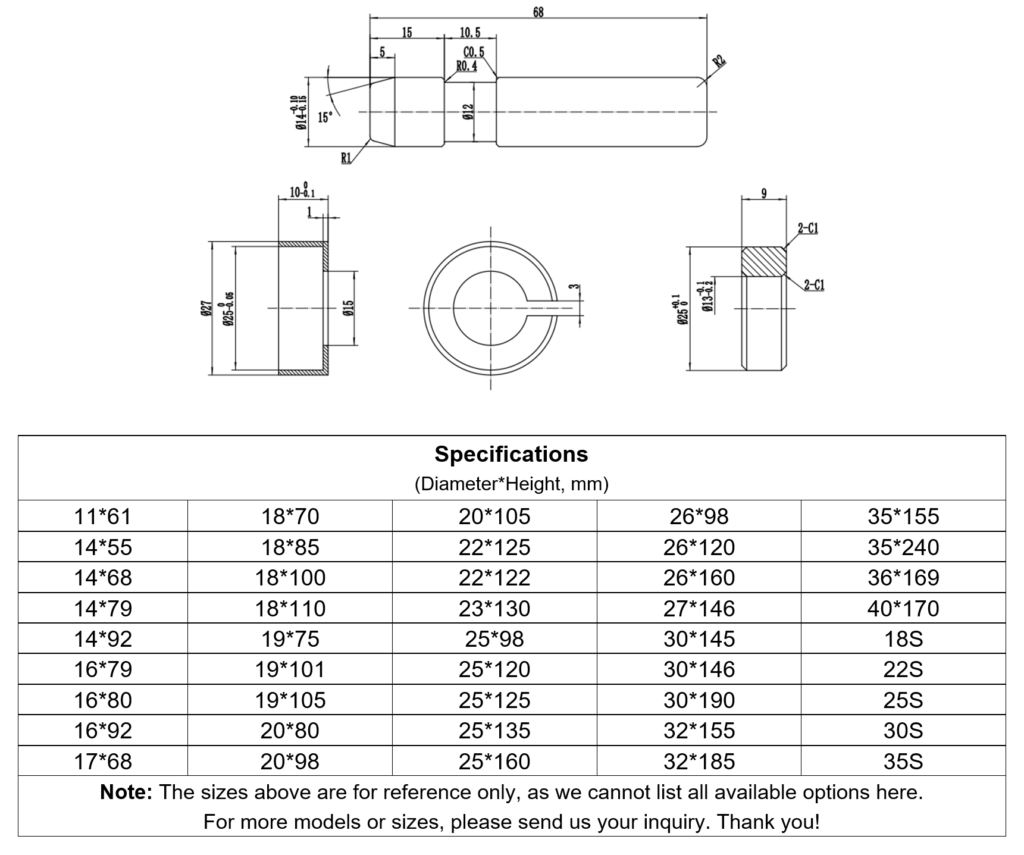

Especificações

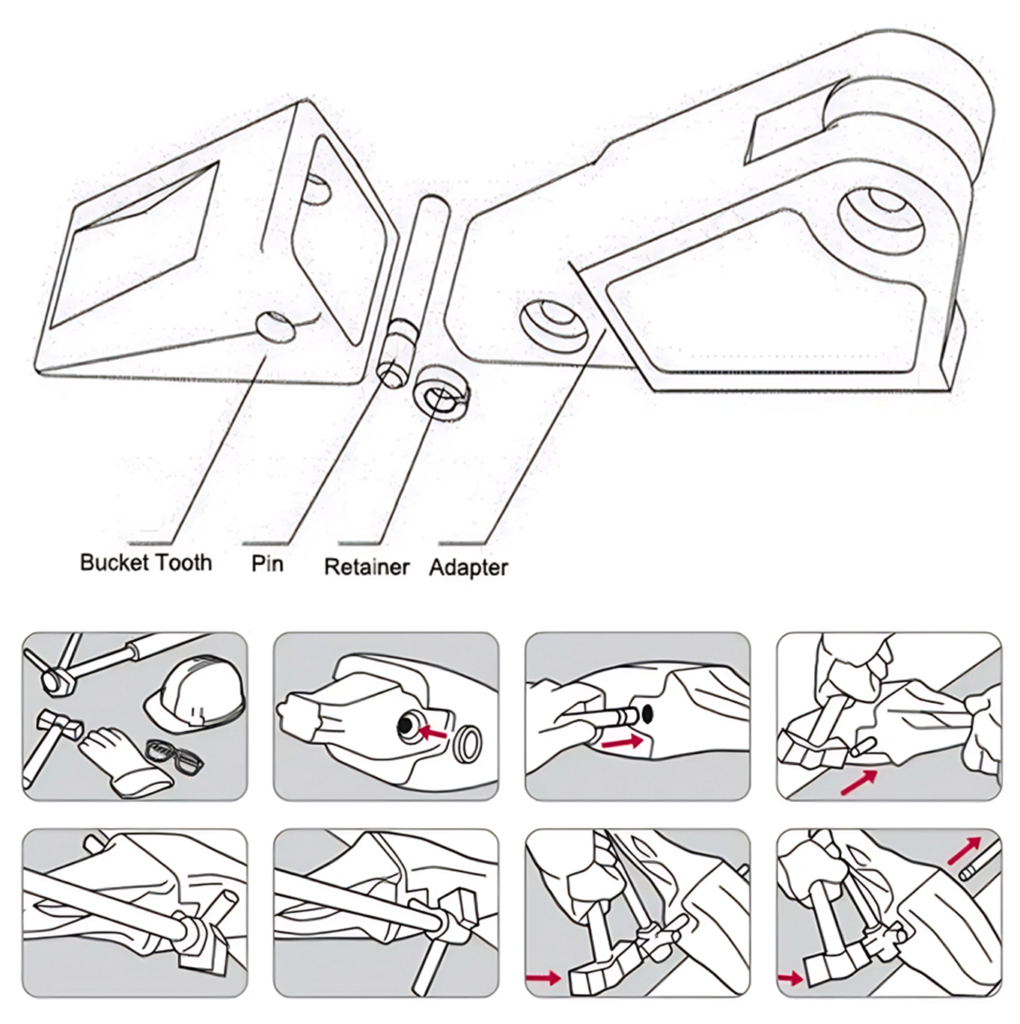

Etapas de instalação

Modelos de produtos

Processo de produção

Como profissional fabricante de peças para escavadeiras, GFM PARTS has first-class production facilities and an experienced team of engineers. With many years of manufacturing experience, it has become a recognized authoritative manufacturer in the industry. The factory introduces advanced processing equipment and strictly controls every link from raw material selection to finished product delivery. Specifically, our production process includes:

Material testing and selection: ensure that each batch of steel meets international standards

Precision machining: use CNC equipment to achieve high-precision machining

Surface treatment: use multiple processes for anti-corrosion and anti-wear processes

Final inspection: multiple quality inspection procedures to ensure product quality

Each process is operated by professional technicians to ensure high consistency and high reliability in the production process. We are well aware of the importance of product quality to engineering safety, so we strictly implement the ISO quality system and strive to provide customers with products and services that exceed expectations.

Embalagem e Envio

Vantagens da fábrica

The GFM factory has an experienced technical team and a complete production process. The factory is spacious and equipped with internationally advanced CNC machinery and automated assembly lines, and each process is subject to strict quality control.

During the research and development and manufacturing of bucket tooth pins, our engineers use high-precision measuring instruments to ensure the accuracy of various dimensions and performance indicators, which makes our products show extremely high stability when used.

In today’s fierce market competition, product standardization can no longer fully meet the needs of all users. Our GFM factory actively responds to customer requirements and provides personalized customization services. Whether you have special size, material or processing technology requirements, we can tailor bucket tooth pin products according to your specific situation. Our customization process mainly includes the following steps:

- Demand communication: understand the customer’s application scenarios and technical requirements in detail

- Scheme design: engineers provide professional advice and draw design drawings

- Production trial production: make samples first, and mass produce after customer verification

- After-sales tracking: installation, commissioning and subsequent maintenance services, one-stop problem solving

Through customized services, you can not only get products that fully meet your requirements, but also gain our sincere and professional service experience, ensure the smooth progress of the project, and reflect the factory’s leading position in the industry.

Practical operation suggestions

In actual use, we provide the following operation suggestions for engineers and maintenance personnel to ensure the best performance of bucket tooth pins:

- Pre-installation inspection: Confirm that the bucket tooth pin size and installation location meet the requirements of CAT E330. It is recommended to prepare basic tools such as wrenches and anti-loosening screw agents in advance

- Regular maintenance: After using for a period of time, regularly check the wear of bucket tooth pins and surrounding parts, and replace parts that show signs of fatigue in time

- Installation adjustment: If slight looseness is found after installation, the installation angle can be adjusted appropriately. If necessary, contact our after-sales technicians

These suggestions are simple and practical. You can apply them to actual work immediately to improve work efficiency and extend the service life of bucket tooth pins.

Choosing our CAT E330 bucket tooth pin products, you can not only enjoy high-quality parts, but also get one-stop customization and considerate after-sales service. We create practical, durable, safe and reliable products for customers with a professional and meticulous attitude. Whether you are an engineering technician or an equipment maintenance expert, you can find solutions that meet your needs here. Please believe us, this is not only a product, but also a safety and trust. We look forward to working with you to create more successful projects and jointly promote industry progress.

Fundada em 2011, a Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd. é uma fabricante experiente especializada em peças de reposição para escavadeiras e tratores de esteira, como peças para material rodante (rolos de esteira, rolos superiores, rodas-guia, rodas dentadas, sapatas de esteira, correntes de esteira, grupos de esteira), parafusos, porcas, pinos, buchas e muito mais. Cobrimos e mantemos em estoque uma ampla gama de peças aplicáveis à maioria das marcas e modelos disponíveis no mercado. As marcas compatíveis incluem Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., abrangendo as principais marcas do mercado.

Perguntas frequentes

Somos um fabricante experiente. Nossa fábrica está localizada em Xiamei Town, Quanzhou. Sua visita é muito bem-vinda.

Forneça-nos o modelo correto da máquina, o número da peça ou algumas especificações. Caso não sejam itens padrão, envie os desenhos.

Geralmente aceitamos T/T; outros termos podem ser negociados.

Claro que sim. Oferecemos serviço OEM. Se você tiver amostras ou desenhos, juntamente com uma solicitação de grande quantidade, podemos personalizar os produtos e oferecer suporte técnico profissional.

A GFM estabeleceu um sistema completo de controle de qualidade, meio ambiente e segurança. Todas as peças passam por rigorosos testes e medidas de controle de qualidade antes da distribuição. Nossa fábrica segue rigorosos padrões de segurança e regulamentações ambientais nos processos de fabricação.

SOLICITE UM ORÇAMENTO AGORA