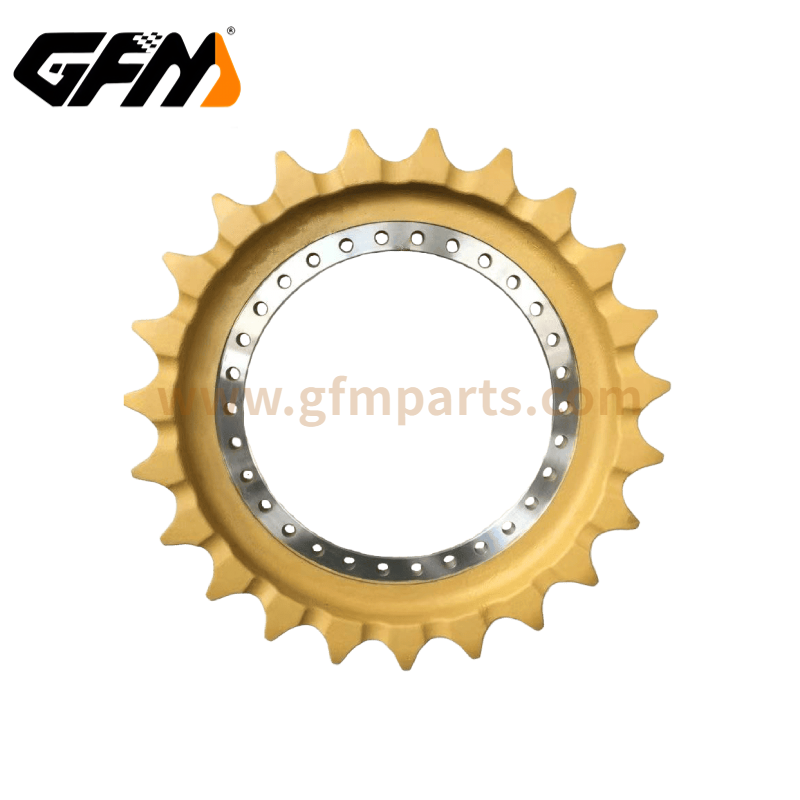

Volvo EC700 Excavator Drive Sprocket

- Qualidade do produto garantida

- Grande oferta

- Preços competitivos

- A maioria das marcas e modelos

- Equipe de Atendimento ao Cliente Útil

- Suporte técnico profissional

Compartilhar

Como profissional fornecedor de rodas dentadas para escavadeira, GFM is well aware of the stringent requirements of Volvo EC700 in large-tonnage earthwork operations. The EC700 dedicated excavator drive sprocket launched by GFM adopts a full-process self-developed process and strict quality control. Once installed, it will show ultra-long service life and smooth power transmission, providing strong support for your on-site operations.

High-strength wear-resistant materials

- The alloy steel material independently developed by GFM is selected. After precision quenching and tempering, the hardness can reach HRC50~55, and the wear resistance is improved by more than 30%.

- The surface is double-heat-treated by carburizing and nitriding to achieve a hardness gradient distribution, which not only ensures the wear resistance of the outer layer, but also retains the toughness of the inner layer, and has stronger impact resistance.

Precision tooth shape design

- Using three-dimensional digital gear modeling software simulation analysis, the tooth shape angle and curve are optimized, the meshing is more stable, and vibration and impact are reduced.

- The tooth top and tooth root parts are treated with corresponding chamfers and chamfers to avoid stress concentration and effectively extend the overall life of the sprocket.

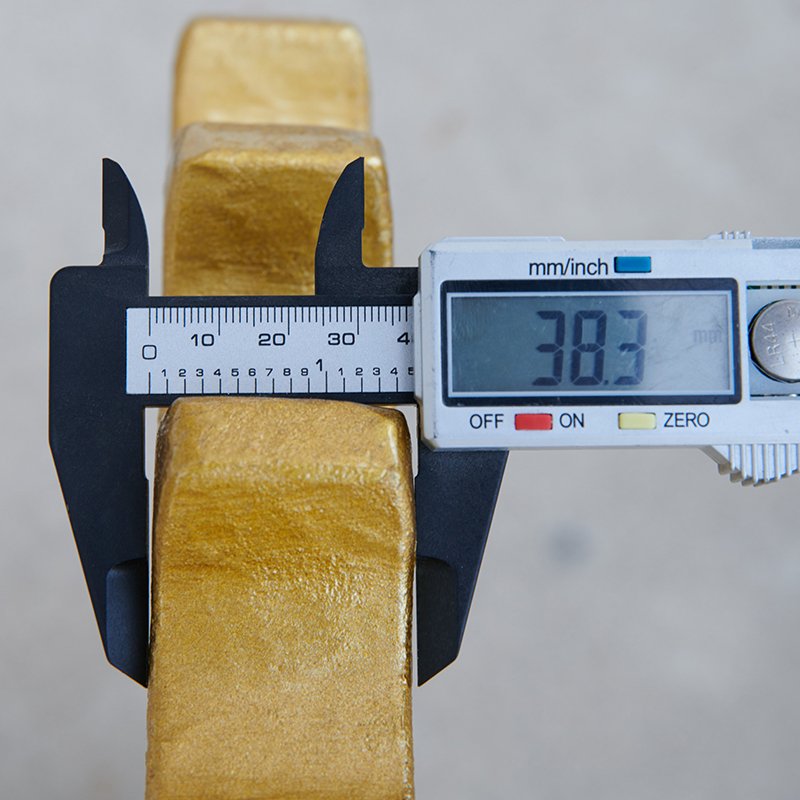

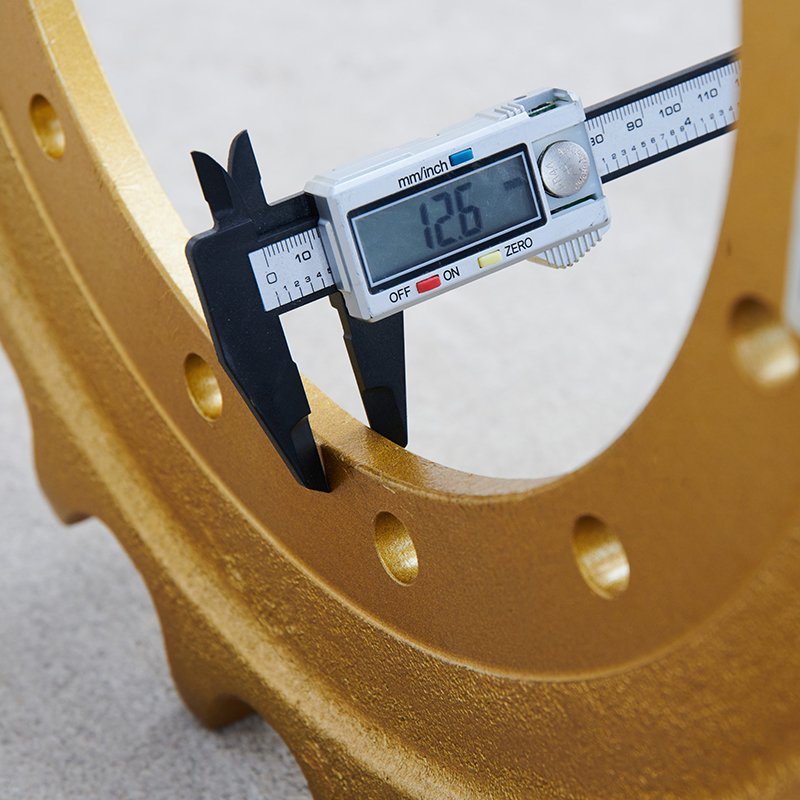

Strict control of dimensional tolerance

- CNC machining throughout the process, dimensional accuracy of ±0.02mm, ensuring perfect match with the original chain rail and roller.

- Each product is strictly tested by a three-coordinate measuring instrument before leaving the factory, with a pass rate of up to 99.8%.

Excellent corrosion resistance

- Through new environmentally friendly phosphate or chrome plating surface treatment, the salt spray test level exceeds 500 hours, and it can adapt to mud and chemical media erosion under various working conditions.

Descrição do produto

- Quantidade mínima: 1 PC

- Método de pagamento: T/T

- Marca: GFM

- Doença: Novo

- Cor: Amarelo, Preto ou Personalizado

- Tempo de espera: 30 dias

- Garantia: 1 ano

- Serviço: OEM ou ODM

- Local de origem: Fujian, China

- Aplicativo: Escavadeira ou trator de esteira

- Embalagem: Palete de madeira padrão para exportação

Características

- Durabilidade Excepcional: Feito de materiais premium para suportar operações pesadas e resistir ao desgaste ao longo do tempo.

- Ajuste perfeito: Projetado para alinhamento preciso com sistemas de esteiras de escavadeiras e tratores, garantindo desempenho ideal.

- Alta capacidade de carga: Projetado para suportar cargas de trabalho intensas, mantendo a resistência e a estabilidade.

- Operação sem esforço: Garante um engate suave com a corrente da esteira, reduzindo a vibração e aumentando a eficiência.

- Desempenho em todas as condições climáticas: Construído para resistir à ferrugem, umidade e temperaturas extremas, garantindo confiabilidade em qualquer ambiente.

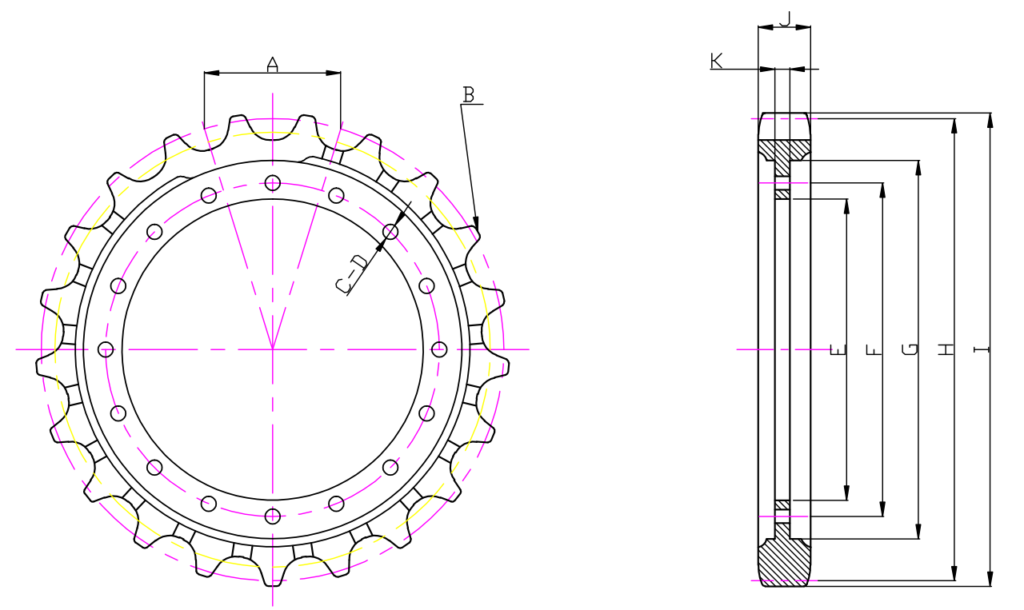

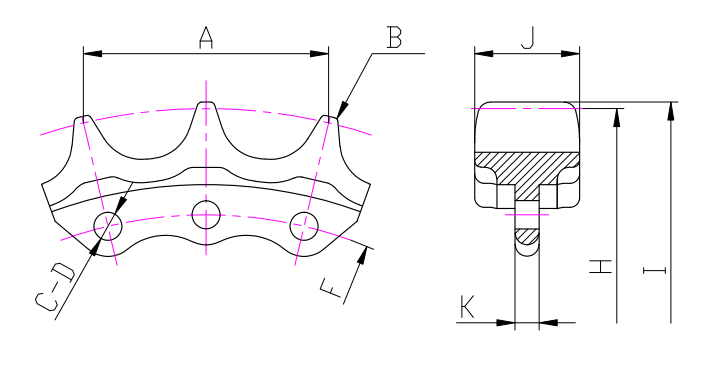

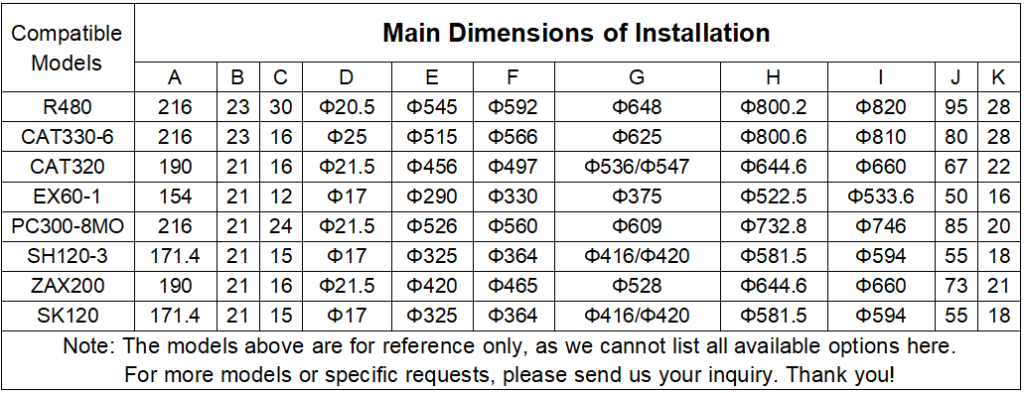

Especificações

Modelos de produtos

Processo de produção

- Forging blank: high-quality alloy steel bars are selected for isothermal forging to ensure that the internal structure is dense and uniform.

- Heat treatment: first quenching and then tempering, and then temperature tempering to eliminate internal stress; the balance of hardness and toughness makes the sprocket less likely to crack under high torque environment.

- CNC machining: precise cutting is carried out through the five-axis linkage CNC machining center, and each tooth surface is repeatedly polished to ensure the tolerance range and surface finish.

- Surface strengthening: high-temperature nitriding or phosphating treatment, combined with shot peening to eliminate residual stress and improve fatigue life.

- Quality inspection: equipped with advanced inspection equipment such as three-coordinate, hardness tester, profilometer, etc., full inspection of multiple indicators such as size, hardness, surface quality, magnetic particle flaw detection, etc.

- Dynamic balance test: The assembly test bench simulates the operation of the actual vehicle, detects vibration and temperature rise, and ensures that the products shipped meet the use requirements 100%.

Embalagem e Envio

Vantagens da fábrica

Professional manufacturing environment

GFM has an independent production workshop, from the receipt of raw materials to the delivery of finished products, each step is controlled on a visual assembly line. The workshop environment is neat and orderly, and independent areas are set up for key processes to ensure stable and safe processing.

Rich processing technology

The factory is equipped with a variety of processing equipment, including CNC milling machines, precision grinders and large CNC machine tools, which can meet the precision processing requirements of sprockets of different specifications. Each process is checked by senior technicians to ensure that each part meets the design requirements.

Strict quality management

The whole process implements incoming material inspection, process inspection and final inspection, and establishes a multi-layer quality inspection system covering raw materials, heat treatment, machining and surface treatment. Each product has a unique production batch number to ensure that the production process is traceable.

Continuous improvement and technical support

GFM focuses on closed-loop cooperation with customer feedback. During the production process, on-site engineers will regularly communicate with customers about usage, adjust process parameters in a timely manner, and optimize product performance; when new projects are promoted, they will provide professional production feasibility analysis to help customers achieve efficient production.

Flexible customization capabilities

We can quickly respond and adjust production plans for different operating environments and special needs – whether it is the selection of different materials, fine-tuning of heat treatment processes, or upgrading of surface protection methods, we can give suggestions and implement them in a short time to ensure that your equipment obtains precisely matched sprockets.

Actionable installation and maintenance suggestions

To help you get on the machine quickly and maintain the best condition, the following are practical installation and maintenance steps and tips:

Preparation before installation

Check the surface cleanliness of the sprocket and chain rail, roller, and wheel hub, and remove grease, iron filings or corrosion.

Use a micrometer and feeler gauge to pre-check the joint clearance to ensure that the clearance between the chain rail and the sprocket meets the original factory specifications (generally 0.15–0.25 mm).

Standard installation process

Place the excavator on a stable surface, cut off the hydraulic and ignition systems, put it in neutral and fix the crawler.

When removing the original sprocket, use a special puller and torque wrench to avoid impact damage to the bearing or wheel hub.

When installing a new sprocket, first manually engage the chain rail to keep the chain tension moderate, and then use a torque wrench to tighten the sprocket bolts according to the original torque value (generally 300-350 N·m).

Daily maintenance tips

After the operation, use a high-pressure water gun to clean the mud and sand on the sprocket and chain rail in time to prevent hard particles from scratching the tooth surface.

Check the sprocket meshing every 50 working hours. If uneven wear is found, adjust the chain rail tensioning bolts or replace the chain plate.

Regularly (200 working hours) add synthetic grease lubricant to the sprocket bearing to ensure smooth sliding of the bearing and reduce wear.

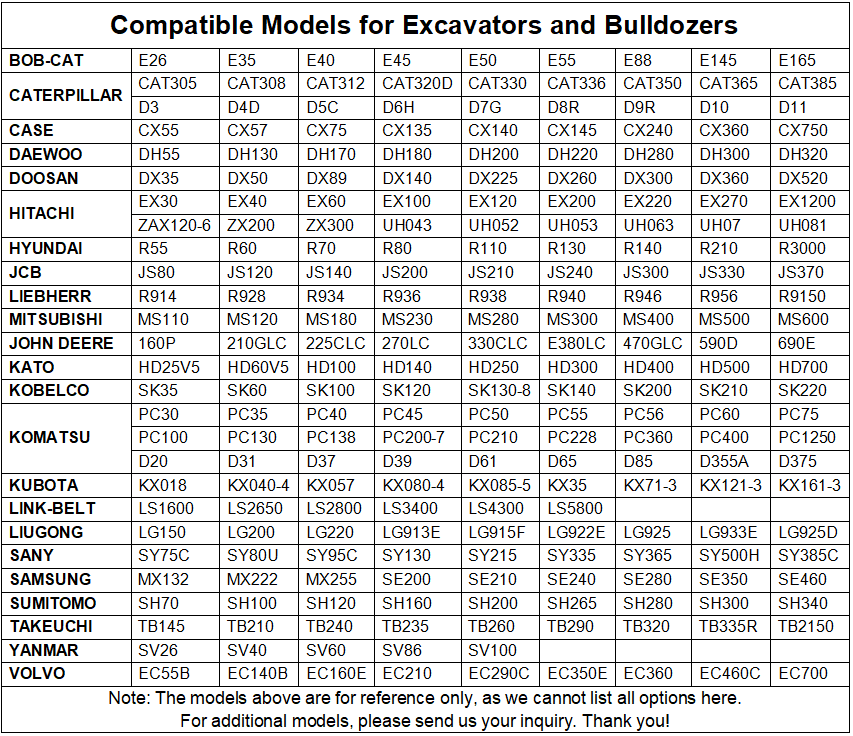

Fundada em 2011, a Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd. é uma fabricante experiente especializada em peças de reposição para escavadeiras e tratores de esteira, como peças para material rodante (rolos de esteira, rolos superiores, rodas-guia, rodas dentadas, sapatas de esteira, correntes de esteira, grupos de esteira), parafusos, porcas, pinos, buchas e muito mais. Cobrimos e mantemos em estoque uma ampla gama de peças aplicáveis à maioria das marcas e modelos disponíveis no mercado. As marcas compatíveis incluem Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., abrangendo as principais marcas do mercado.

Perguntas frequentes

Somos um fabricante experiente. Nossa fábrica está localizada em Xiamei Town, Quanzhou. Sua visita é muito bem-vinda.

Forneça-nos o modelo correto da máquina, o número da peça ou algumas especificações. Caso não sejam itens padrão, envie os desenhos.

Geralmente aceitamos T/T; outros termos podem ser negociados.

Claro que sim. Oferecemos serviço OEM. Se você tiver amostras ou desenhos, juntamente com uma solicitação de grande quantidade, podemos personalizar os produtos e oferecer suporte técnico profissional.

A GFM estabeleceu um sistema completo de controle de qualidade, meio ambiente e segurança. Todas as peças passam por rigorosos testes e medidas de controle de qualidade antes da distribuição. Nossa fábrica segue rigorosos padrões de segurança e regulamentações ambientais nos processos de fabricação.

SOLICITE UM ORÇAMENTO AGORA

Produtos relacionados

-

TREM RODANTE

Fabricante de grupo de esteiras para escavadeira

-

TREM RODANTE

Fabricante de rolos inferiores de alta qualidade