Rolo transportador para escavadeira Komatsu PC800 por atacado 195-30-00580/KM2160

- Qualidade do produto garantida

- Grande oferta

- Preços competitivos

- A maioria das marcas e modelos

- Equipe de Atendimento ao Cliente Útil

- Suporte técnico profissional

Compartilhar

In the high-intensity working environment of the excavator, the excavator carrier roller is one of the core components that supports the crawler and guides its smooth operation. Its quality directly affects the durability and stability of the whole machine’s walking system. GFM provides special top roller for large excavators suitable for the Komatsu PC800 model. It adopts high-strength forged steel material and precision heat treatment process to ensure excellent load-bearing performance and service life, which is an ideal choice for heavy-duty construction environments.

This carrier roller is specially adapted for Komatsu PC800 heavy excavators and has the following key performance characteristics:

Accurately match the original factory standards: the size, axis, hole spacing, and installation interface fully meet the original specifications of Komatsu, ensuring one-click replacement without additional modification.

Wear-resistant steel forged body: The whole body is made of 50Mn or 40Mn2 high-quality alloy steel, which has been forged and tempered for multiple times, and has strong impact resistance. It is especially suitable for high-impact environments such as rock conditions, mining, and crushing operations.

High-frequency quenching process: The wheel rim surface is treated with high-frequency induction quenching, and the hardness can reach HRC52-58, which effectively delays wear and significantly extends the service life.

Thickened wall design: The wheel body is thicker and stronger than conventional rollers, effectively supports the track chain and the weight of the whole machine, and runs more stably.

Double oil seal protection structure: imported double-channel floating seals are used to isolate dust and sand intrusion, and the internal lubricating oil is extremely sealed to ensure long-term maintenance-free operation.

Descrição do produto

- Quantidade mínima: 1 PC

- Método de pagamento: T/T

- Marca: GFM

- Doença: Novo

- Cor: Amarelo, Preto ou Personalizado

- Tempo de espera: 30 dias

- Garantia: 1 ano

- Serviço: OEM ou ODM

- Local de origem: Fujian, China

- Aplicativo: Bulldozer or Crawler Tractor

- Embalagem: Palete de madeira padrão para exportação

Características

- Long-Lasting Durability: Crafted from high-grade, wear-resistant steel for maximum strength and extended lifespan.

- Selado e Lubrificado: Fully sealed design keeps out dirt, water, and contaminants, minimizing wear and maintenance.

- Operação suave: Precision-engineered to provide efficient and stable support for the upper portion of the track.

- Corrosion Resistance: Corrosion-resistant surface treatments ensure reliable operation in harsh environments.

- Serve para vários modelos: Designed to fit a wide range of excavator and bulldozer models for various applications.

- Proven Toughness: Tested to perform reliably under extreme conditions, reducing downtime and increasing productivity.

At GFM Factory, our carrier rollers are built to optimize your machinery’s performance, ensuring smoother track operations and extended equipment life.

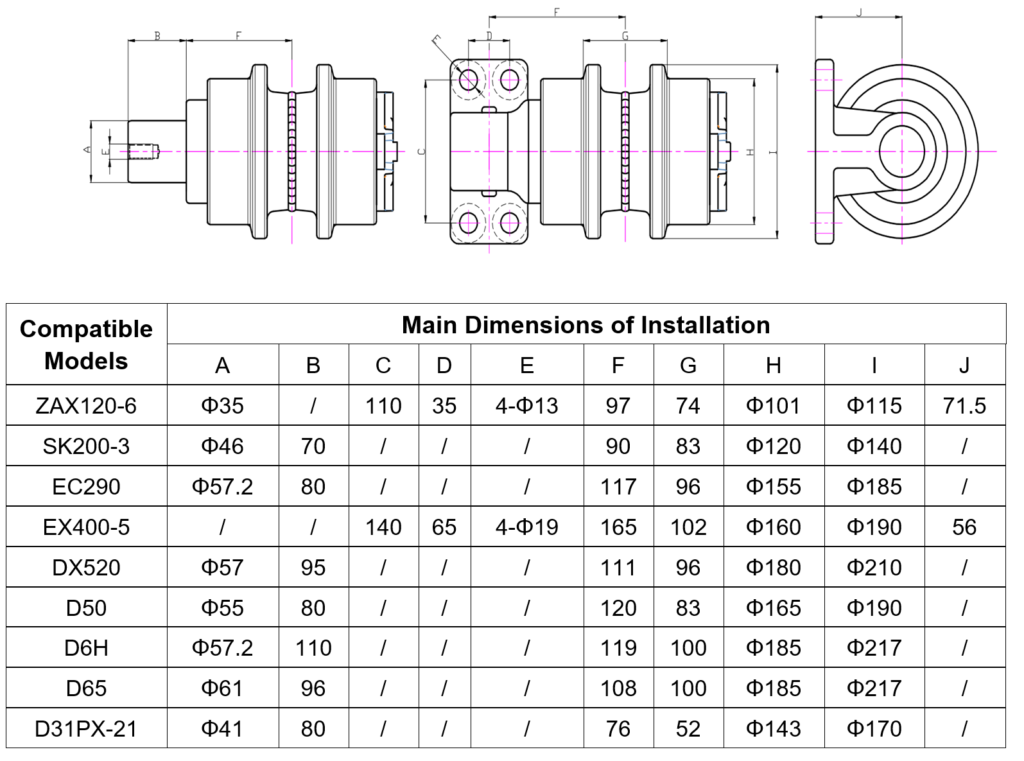

Modelos de produtos

Processo de produção

The production process is divided into four stages: raw material selection, CNC machining, surface treatment and final inspection. Each link is monitored by professionals to ensure that the process is smooth and without omissions.

- Seleção de matéria-prima: Strictly select qualified suppliers to ensure that the materials are safe and environmentally friendly.

- CNC machining: High-precision equipment monitors dimensional errors in real time to ensure product consistency.

- Tratamento de superfície: Use environmentally friendly technology to improve durability and appearance.

- Final inspection: Each product undergoes multiple tests before leaving the factory to ensure zero defects.

Through this rigorous process, we can provide customers with stable and reliable products, reflecting professional knowledge and technical strength.

Embalagem e Envio

Vantagens da fábrica

As an excavator carrier roller factory with many years of deep cultivation in the industry, GFM has rich experience in the production of peças do material rodante da escavadeira and perfect industrial chain supporting capabilities:

- Modernized machining center: equipped with vertical machining center, CNC lathe, CNC milling machine and other advanced equipment to support large-scale and precision machining tasks.

- Annual production capacity of one million wheels: with annual production capacity of more than 1 million wheels of various models, serving hundreds of OEMs and parts dealers around the world.

- Passed ISO9001 and CE certification: full process quality system management, all factory products can provide quality traceability and material reports.

- Rich adaptation model library: adapted to Komatsu, Caterpillar, Hitachi, Doosan, Hyundai, Volvo and many other brands.

- Global customer cooperation cases: At present, the products have been exported to more than 50 countries including Europe, America, the Middle East, Southeast Asia, Latin America, etc., and are well received by customers.

Customized service: meet your personalized needs

GFM not only provides standardized upper roller excavator products, but also supports OEM & ODM customized services to help customers achieve higher adaptability, stronger performance, and better cost-effectiveness:

- Support drawing sample customization: can quickly develop molds according to the drawings or samples provided by customers, and customize exclusive sizes and structures.

- Personalized brand service: can laser engrave customer brand LOGO, packaging labels, corporate identification colors to enhance brand recognition.

- Multi-specification batch support: support delivery from small batch to large batch, flexible delivery time, meet the requirements of engineering project cycle.

- Professional after-sales response mechanism: equipped with overseas technical service team, provide technical guidance, after-sales tracking and fast delivery of spare parts.

Welcome to contact us at any time to get a quote or technical information, GFM looks forward to becoming your long-term and stable accessories partner.

Fundada em 2011, a Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd. é uma fabricante experiente especializada em peças de reposição para escavadeiras e tratores de esteira, como peças para material rodante (rolos de esteira, rolos superiores, rodas-guia, rodas dentadas, sapatas de esteira, correntes de esteira, grupos de esteira), parafusos, porcas, pinos, buchas e muito mais. Cobrimos e mantemos em estoque uma ampla gama de peças aplicáveis à maioria das marcas e modelos disponíveis no mercado. As marcas compatíveis incluem Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., abrangendo as principais marcas do mercado.

Perguntas frequentes

Somos um fabricante experiente. Nossa fábrica está localizada em Xiamei Town, Quanzhou. Sua visita é muito bem-vinda.

Forneça-nos o modelo correto da máquina, o número da peça ou algumas especificações. Caso não sejam itens padrão, envie os desenhos.

Geralmente aceitamos T/T; outros termos podem ser negociados.

Claro que sim. Oferecemos serviço OEM. Se você tiver amostras ou desenhos, juntamente com uma solicitação de grande quantidade, podemos personalizar os produtos e oferecer suporte técnico profissional.

A GFM estabeleceu um sistema completo de controle de qualidade, meio ambiente e segurança. Todas as peças passam por rigorosos testes e medidas de controle de qualidade antes da distribuição. Nossa fábrica segue rigorosos padrões de segurança e regulamentações ambientais nos processos de fabricação.

SOLICITE UM ORÇAMENTO AGORA

Produtos relacionados

-

TREM RODANTE

Melhor Fábrica de Rolos Inferiores para Bulldozer

-

TREM RODANTE

Fabricante de correntes para esteiras de escavadeira

-

TREM RODANTE

Fabricante de rolos inferiores de alta qualidade