As the core of the excavator’s traveling system, the crawler assembly’s performance directly determines the stability and durability of the equipment under complex working conditions. As an industry leading excavator undercarriage parts supplier, GFM relies on professional technology and advanced processes to provide excellent track assembly products to customers around the world.

What is a excavator track assembly?

The track assembly is a key component in the excavator operating system to support the weight of the equipment and achieve smooth walking. It distributes the weight of the equipment through continuous contact between the crawler track and the ground, improving traction and stability. Especially in muddy, steep slopes, soft or rocky terrain, the track assembly can significantly reduce ground pressure and provide superior passability and grip.

The composition of the track assembly

The track assembly is a highly collaborative system, composed of a variety of components that are precisely coordinated:

Track Shoes:

The manufacturing material is usually high-strength steel, and the surface undergoes a heat treatment process to improve wear resistance and impact resistance. The design of track shoes needs to take into account grip, durability and adaptability to the ground.

Track Chains:

The chain rails connect the track shoes to form a circular track system. Its precise pitch design reduces wear and increases operating efficiency.

Drive Sprockets:

The driving wheel transmits power to the chain rail through a hydraulic system or transmission device. Its tooth structure needs to match the chain rail pitch to ensure efficient and smooth power transmission.

Track Rollers:

The rollers bear the weight of the equipment and distribute it evenly on the tracks to ensure smooth operation of the equipment. Its sealing structure can effectively prevent sediment from entering and extend its life.

Idlers:

Installed on the front end of the crawler track, it is used to maintain the correct track of the crawler track and absorb the impact force during operation.

Track Tensioning System:

Use hydraulic or mechanical devices to adjust track tension to prevent track derailment or excessive slack.

Working principle of track assembly

The track assembly drives the chain rail to run through the rotation of the drive wheel, and the track pads generate friction with the ground to form traction. Track rollers distribute the load and maintain smooth operation, and guide wheels and tensioners ensure that the track system always remains within the correct trajectory. When the excavator turns, the crawler assembly realizes flexible steering by stopping or decelerating one side of the crawler. This design allows the excavator to turn on the spot in a small space, improving work efficiency.

Routine maintenance of track assembly

In order to extend the service life of the crawler assembly and ensure the operating efficiency of the equipment, routine maintenance is particularly important:

Cleaning and inspection:

After each operation, remove dirt and gravel from the crawler tracks and chain rails to prevent increased wear or component jamming. At the same time, check the integrity of the track shoes and chain rails, and replace damaged parts in time.

Adjust track tension:

Tracks with moderate tightness help reduce abnormal wear of components. Tension adjustment must be in accordance with the equipment manual to avoid over-tensioning or over-relaxation.

Lubrication and anti-corrosion:

Regularly add lubricating oil to the rollers, chain rails and guide wheels to reduce friction and noise. In addition, when the working environment is humid, anti-rust treatment should be carried out to prevent corrosion of parts.

Monitor wear and tear:

Regularly measure the thickness of the track pads, the wear degree of the chain rails and whether there are dents in the circumference of the rollers to ensure safe operation.

Operating specifications:

Avoid working in extreme terrain or overload conditions for a long time, and adjust the operation strategy if necessary to reduce unnecessary component stress.

GFM High Quality Track Group

High Durability – Built with premium alloy steel to withstand heavy use.

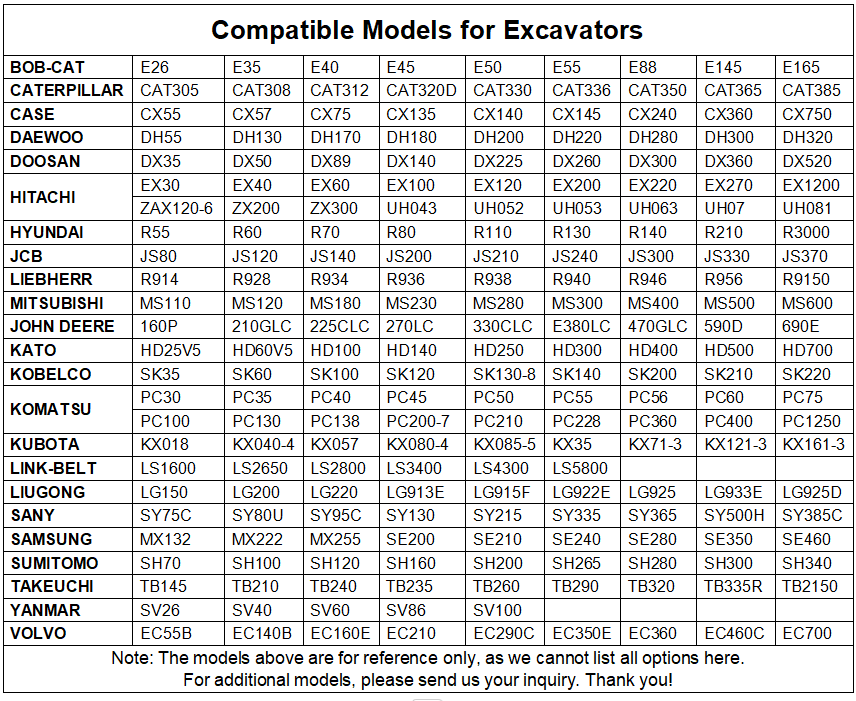

Perfect Fit – Precision-crafted for seamless compatibility with major excavator brands.

Enhanced Strength – Heat-treated for superior hardness and wear resistance.

Corrosion Resistant – Special coating protects against rust in tough conditions.

Smooth Operation – Low friction design ensures quiet and efficient performance.

Quick Installation – Easy to assemble, saving time and reducing downtime.

Advantages of GFM track assembly

As a technology pioneer in the field of track assemblies, GFM provides customers with customized solutions to meet the needs of different working conditions. The following are the core competencies of GFM track assembly:

High-quality material selection:

We select alloy steel with extremely high wear resistance and combine it with advanced heat treatment technology to ensure the durability of the product in harsh environments.

Precision manufacturing process:

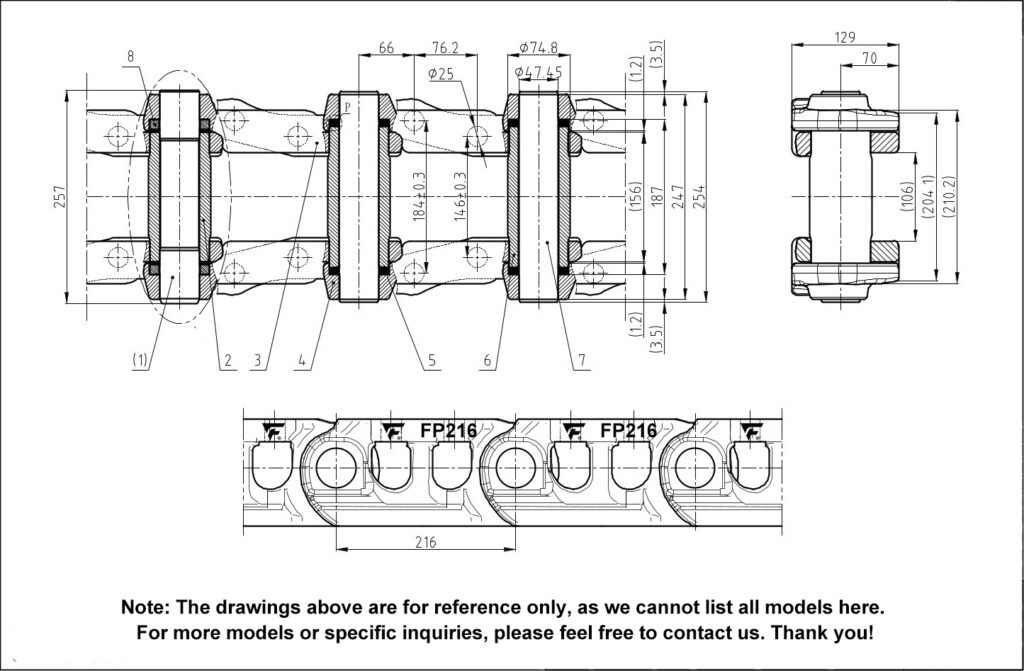

All components undergo strict CNC processing and assembly, with tolerances controlled at the micron level to ensure high stability of system operation.

Technical innovation design:

GFM continues to optimize the track pad structure and chain rail pitch design to improve traction while reducing ground damage to the environment.

Diverse product selection:

For different application scenarios such as mining, construction and forestry, GFM provides crawler assemblies of various specifications and models.

Perfect after-sales service:

We not only provide regular maintenance guidance, but also provide customers with quick replacement parts and technical support services to help equipment maintain optimal performance.

The performance of the track assembly directly determines the excavator’s operating capability and economic benefits in complex terrain. Through scientific maintenance methods and selection of high-quality products, the operating efficiency and service life of the equipment can be greatly improved. With its advanced technology, excellent product quality and global service network, GFM is committed to providing customers with optimal solutions and assisting the successful implementation of various engineering projects.

Email: henry@gfmparts.com

Whatsapp: +86 17705953659