Carrier roller excavator is an important part of the excavator chassis system and plays a decisive role in the stability and service life of the equipment. Whether it is a complex construction environment or a high-intensity operation requirement, the performance of the carrier roller is crucial.

What is an excavator carrier roller?

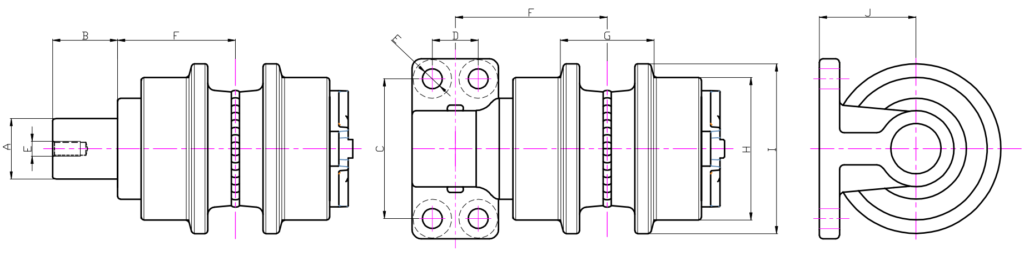

The excavator carrier roller is one of the important components of the excavator’s walking device. It is located in the crawler chassis system and is in direct contact with the crawler. Its main function is to support the weight of the excavator and guide the crawler to run smoothly, thereby ensuring the stability and efficient operation of the equipment in various complex terrains. The performance of the support wheel is directly related to the overall working efficiency and service life of the excavator, and it is a key component that cannot be ignored in the chassis system.

The function and principle of the excavator carrier roller

Function

- Supporting equipment weight: The carrier rollers are distributed on both sides of the crawler chassis, which can evenly share the weight of the excavator, prevent direct friction between the crawler and the ground, and reduce the workload of the crawler.

- Guide the crawler track: By cooperating with the crawler track, the carrier roller ensures that the crawler track runs along the predetermined track, avoids the crawler track from deviating or derailing, and ensures the stability of the excavator.

- Absorb impact force: During the operation of the equipment, uneven ground may cause impact force, and the carrier roller can effectively absorb these impacts and reduce the loss of the chassis system and crawler track.

- Improve equipment stability: The carrier roller an important role in weight distribution and dynamic balance, especially when operating on steep slopes or complex terrain.

Principle

The carrier roller achieves efficient rotation through internal high-strength bearings and sealing systems, and its external part transmits power through the crawler track and the drive wheel. The surface of the carrier roller is usually subjected to a special heat treatment process to increase hardness and wear resistance, so that it can maintain long-term stable operation under high load and harsh working conditions. High-quality carrier roller design not only focuses on durability, but also takes into account lightweight and high efficiency.

How to judge the quality of the carrier roller?

Selecting a high-quality carrier roller is an important step to ensure the normal operation of the excavator. Here are a few key indicators:

Material:

- High-quality carrier roller are usually made of high-strength alloy steel, and are tempered and surface hardened to make them highly impact-resistant and wear-resistant.

- The surface is treated with a corrosion-resistant coating to adapt to humid or corrosive environments.

Processing accuracy:

- High-precision processing ensures that the outer circle of the carrier roller fits perfectly with the track, running smoothly and wearing evenly.

- Strict error control, such as outer diameter roundness and bearing fit clearance, is directly related to the product life.

Sealing:

- The quality of the sealing ring is an important criterion for measuring the performance of the carrier roller. Poor sealing performance may cause mud and water to enter the interior, thereby damaging the bearing.

- High-performance sealing systems can extend the life of the carrier roller and reduce maintenance costs.

Surface hardness:

- The surface hardness of the carrier roller is usually controlled between HRC48-58, which can effectively resist wear and maintain strong impact resistance.

Brand reputation:

- Choose a manufacturer with a good industry reputation, whose products are usually rigorously tested and can provide stable quality and excellent after-sales service.

How to maintain the carrier roller on a daily basis?

The service life of the carrier roller is closely related to daily maintenance. Here are some maintenance suggestions:

Regular cleaning:

- When used under harsh working conditions, mud and impurities are easy to adhere to the surface of the carrier roller. These foreign objects should be removed regularly to avoid damage to the bearings and seals.

Check the wear:

- Regularly check whether there are obvious grooves, cracks or abnormal wear on the surface of the carrier roller; pay attention to check whether the bearing is loose or stuck.

Lubrication and maintenance:

- Add an appropriate amount of lubricating oil to the carrier roller bearing system to ensure its flexible rotation and reduce internal wear.

- Adjust the lubrication cycle according to the frequency of working conditions to avoid excessive or insufficient lubrication.

Pay attention to the seal ring:

- Regularly check the status of the seal ring, and replace it in time if it is found to be aging, cracked or damaged to prevent external foreign objects from invading.

Keep the track tension moderate:

- If the track is too tight, the carrier roller may be subjected to excessive pressure, and if it is too loose, it may affect the guiding effect. Therefore, it is very important to adjust the track tension regularly.

Advantages of GFM carrier roller

As a leading excavator carrier roller supplier, GFM carrier rollers have won the trust of global customers with excellent quality and professional services. The following are our core advantages:

Advanced production process:

- GFM carrier roller adopt internationally leading heat treatment processes to ensure that the products have high strength and high wear resistance.

- High-precision CNC processing technology ensures the dimensional accuracy and quality consistency of each product.

High-quality material selection:

- All carrier rollers are made of high-quality alloy steel, which has undergone multiple strict screening and enhanced process treatments.

- The surface is coated with a special anti-corrosion layer, which can be used for a long time in harsh environments such as wet and muddy.

Strict quality inspection:

- Carrier roller must pass multiple tests before leaving the factory, including hardness test, wear test, impact test and sealing performance test to ensure that they meet or even exceed industry standards.

Professional technical support:

- GFM has an experienced engineering team that can provide professional advice and solutions according to customer needs.

- Our technical support covers the entire process service from product selection to usage guidance.

Customized service:

- According to the equipment requirements of different customers, we provide personalized customization services for sprockets, including specific sizes, materials and coatings.

Perfect after-sales guarantee:

- GFM provides global after-sales service, quickly responds to customer issues, and ensures that the equipment is always in the best condition.

Carrier rollers are an indispensable core component in the excavator chassis system, and their performance directly affects the operating efficiency and construction effect of the equipment. Choosing high-quality carrier rollers and combining them with scientific maintenance methods can effectively extend the service life of the equipment and reduce operating costs. GFM provides customers with reliable carrier roller solutions with industry-leading technology, excellent product quality and comprehensive services. If you need to know more or purchase GFM carrier rollers, please feel free to contact our team, we will serve you wholeheartedly!

Email: henry@gfmparts.com

Whatsapp: +86 17705953659