In the field of construction machinery, track excavators and wheeled excavators are two main types of construction equipment. Each of them has a unique design and function that can meet the needs of different construction scenarios.

Definition and characteristics of track excavators and wheeled excavators

Track excavators

Track excavators use crawlers as walking devices, and their chassis design is similar to that of a tank, which can provide excellent traction and stability. This type of excavator is usually used on rugged, soft or uneven ground.

Features:

Strong traction, suitable for working in harsh environments such as mud, wetlands or sand.

High body stability, suitable for large-scale earthwork operations.

Small turning radius, suitable for operation in small spaces.

Wheeled excavators

Wheeled excavators use rubber tires as walking devices, and their flexibility and maneuverability make them ideal for urban construction and highway operations.

Features:

Fast driving speed, easy to move between different construction sites.

It causes less damage to the road surface and is suitable for construction on urban roads or hard ground.

It can quickly adjust the position and improve work efficiency.

The benefits of using crawler excavators and wheeled excavators

The benefits of track excavators

Strong terrain adaptability

Crawler excavators perform well in complex terrains such as mud and wetlands. For example, in water conservancy projects, the construction environment is often soft soil or wetland areas, and crawler excavators can provide a stable operating platform to prevent equipment from sinking into the ground.

High load capacity

Crawler excavators are often used in large mines and earthworks, such as mining ore or moving large amounts of earth and stone. Its chassis design allows for a larger operating load, thereby speeding up the progress of the project.

Low ground pressure

In agricultural irrigation projects or wetland restoration projects, crawler excavators are not easy to damage the surface due to their large ground contact area, protecting the geological structure of the construction area.

Benefits of wheeled excavators

Convenient mobility

In urban construction projects, such as municipal pipeline maintenance or road repair, wheeled excavators can quickly travel to the construction site without trailer transportation, greatly saving time and cost.

Versatility

Wheeled excavators are able to quickly change attachments, such as hydraulic hammers for crushing operations and buckets for clearing gravel. This makes it particularly practical in urban building demolition and site cleanup.

Low operating costs

Since they mainly operate on hard ground, wheeled excavators have less wear on the traveling device and lower daily maintenance costs, making them suitable for use by small and medium-sized enterprises.

Advantages of crawler excavators and wheeled excavators

Advantages of track excavators

- Super stability: In mountain road construction, crawler excavators can operate stably on inclined slopes without affecting the safety of operations due to steep terrain.

- High-intensity operation capacity: It is suitable for projects that require long-term and high-intensity excavation, such as foundation excavation for large bridges.

- High traction: In mining areas or quarries, crawler excavators can easily drag heavy tools or vehicles to complete handling tasks.

Advantages of wheeled excavators

- High flexibility: In crowded city streets or limited construction sites, wheeled excavators can quickly adjust their positions. For example, in the renovation of old urban areas, the flexibility of the equipment directly affects the construction efficiency.

- Rapid transfer capability: When multiple project sites are under construction at the same time, wheeled excavators can drive to the new construction site by themselves without waiting for transportation equipment.

- Easy maintenance: Since wheeled excavators use rubber tires, their walking system is simpler, and tires can be quickly replaced when problems occur, reducing downtime.

Why choose track excavators and wheeled excavators?

- Construction requirements: Crawler excavators are the first choice if you need to work in complex terrain or large-scale construction scenarios. In scenes with better ground conditions such as cities or highways, wheeled excavators are more suitable.

- Budget considerations: Crawler excavators usually have a higher initial investment, but are suitable for long-term large-scale projects; wheeled excavators have lower operating costs.

- Efficiency and flexibility: Choosing the right equipment according to the characteristics of the construction site can greatly improve construction efficiency.

Precautions before purchase

- Identify the construction scenario: Choose the right excavator according to the project type and terrain conditions.

- Evaluate equipment performance: Check key parameters such as engine power, digging force, and operating radius.

- Consider maintenance costs: Understand the daily maintenance needs and spare parts supply of the equipment.

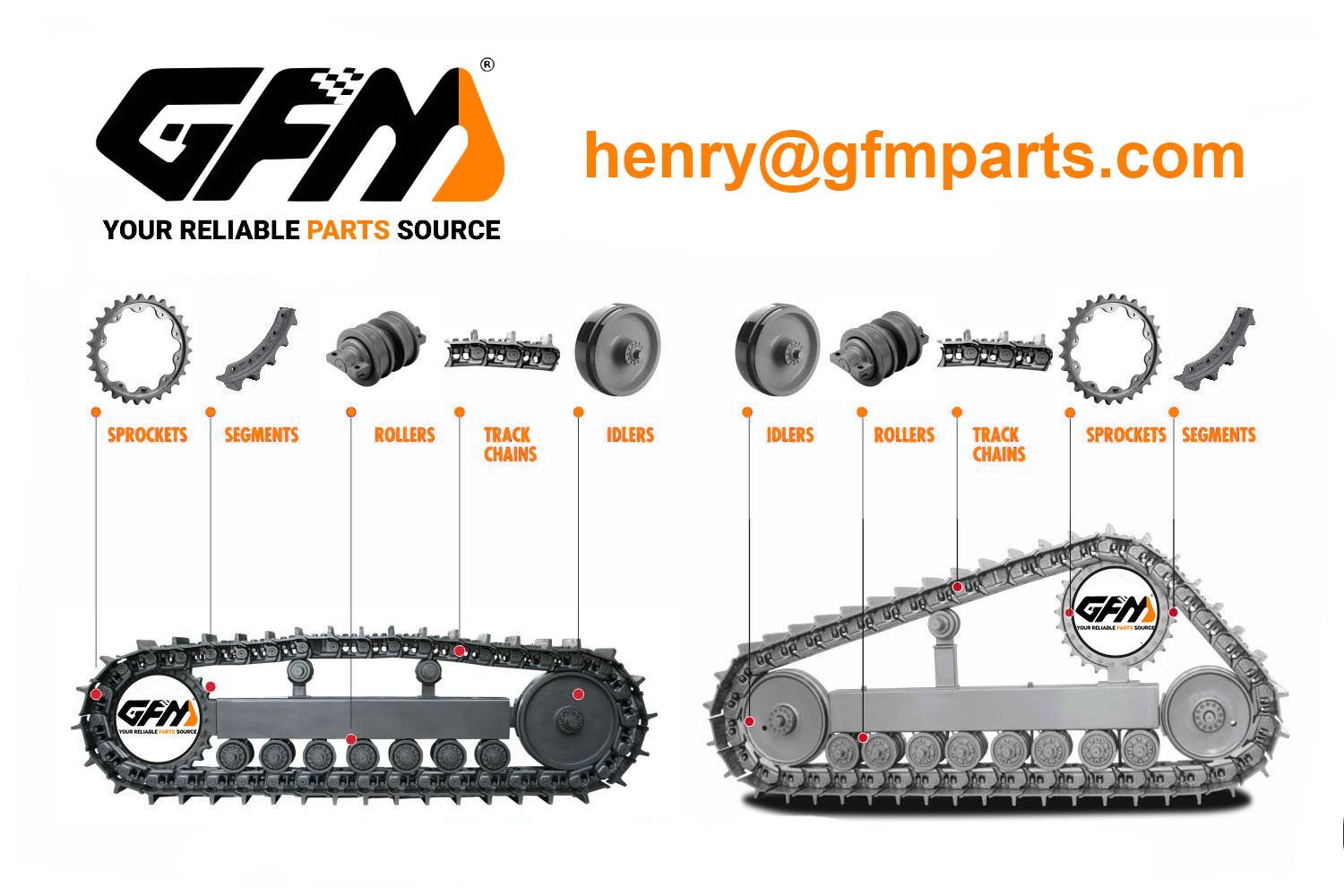

- Choose a reliable brand: As a professional excavator chassis manufacturer, GFM provides high-quality crawler and wheeled components to ensure stable equipment performance.

- Trial run: It is recommended to test the machine before purchase to verify the suitability and performance of the equipment.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Track excavators and wheeled excavators have their own advantages. Choosing the right equipment can not only improve construction efficiency, but also optimize the cost structure. As a professional manufacturer of undercarriage parts, GFM excavator track supplier is committed to providing customers with high-quality chassis solutions.