Mini excavators are essential equipment in many construction and engineering projects. To ensure that they perform at their best in a variety of working environments, regular maintenance and care are essential. GFM excavator parts manufacturers provide you with a comprehensive “Mini Excavator Maintenance Guide” that covers everything from daily inspections to long-term maintenance to help you reduce equipment failures, improve work efficiency, and reduce long-term operating costs.

Guide to Keeping Your Mini Excavator Running at Optimal Efficiency

To ensure that your mini excavator maintains optimal efficiency during construction, the key is to continuously monitor and perform repairs in a timely manner. Here are a few tips to keep it running efficiently:

- Check the hydraulic system regularly: The hydraulic system is the heart of the small excavator. Make sure the hydraulic oil level and oil quality meet the requirements. Regularly changing the hydraulic oil can avoid hydraulic system failure.

- Check engine performance: The engine needs to maintain a proper operating temperature. Check the cooling system and radiator regularly to ensure that there are no leaks or blockages.

- Lubrication system inspection: Keeping each moving part lubricated can reduce friction, improve mechanical efficiency, and avoid unnecessary wear.

Before starting work

Before each work, it is very important to check the main functions and safety settings of the excavator. Make sure all parts are working properly to prevent failures during work.

- Check fuel and oil: Make sure there is enough fuel and hydraulic oil, and check the quality of the oil.

- Check the track and chassis: Check whether the track is damaged or loose, and make sure the chassis is clean and free of debris.

- Check the engine and cooling system: Check whether the engine coolant is sufficient and make sure the radiator is not blocked.

- Check the work lights and dashboard: Make sure the work lights, warning lights, dashboards, etc. are operating normally to avoid mistakes during work.

When you are ready to start working

When starting work, in addition to the preliminary inspection, you need to pay special attention to the following matters:

- Adjust the working mode: Different working tasks may require different operating modes. Make sure you choose the right mode to improve work efficiency.

- Set a reasonable workload: Avoid overloading the excavator, especially when working on soft soil or unstable terrain. Excessive load will accelerate machine wear.

Proactive maintenance of the excavator

Proactive maintenance can greatly reduce the possibility of failure and increase the service life of the machine. Regular cleaning of the machine, lubrication of joints and inspection of important parts are the key to daily maintenance.

- Regular cleaning of equipment: Cleaning the machine can effectively remove dirt such as mud and dust, and reduce wear on mechanical parts.

- Check and replace wearing parts: Wearing parts such as tires, tracks, and seals should be checked regularly and replaced in time.

Follow regular maintenance procedures

Regular maintenance is the basis for ensuring the long-term and stable operation of small excavators. Each small excavator should follow the maintenance manual provided by the manufacturer and perform maintenance according to the recommended cycle. Common maintenance items include:

- Change the engine oil and filter: Regularly changing the engine oil and filter can effectively protect the engine and improve fuel efficiency.

- Check and replace the air filter: Make sure the engine’s air filter is clean to prevent dust from entering the engine system.

- Check the fuel system: Check the fuel line regularly to ensure there are no leaks and the oil pump is working properly.

The following are recommended service intervals

Different excavator maintenance service intervals may vary. Here are some recommended intervals for common maintenance items:

- Every 100 hours: Check the hydraulic oil and oil level, check the hydraulic oil filter.

- Every 250 hours: Change the engine oil and filter, check the fuel system.

- Every 500 hours: Check the track tension and clean the cooling system.

- Every 1000 hours: Fully check the hydraulic system, replace the air filter, and check the hydraulic oil temperature.

Common excavator maintenance problems

Some common excavator maintenance problems include:

- Hydraulic system failure: It may be caused by poor hydraulic oil quality or a clogged hydraulic filter.

- Engine overheating: It is usually caused by a clogged cooling system or insufficient coolant.

- Track wear: Excessive use or failure to check in time can cause premature wear of the track.

Maintenance tips for excavator undercarriage

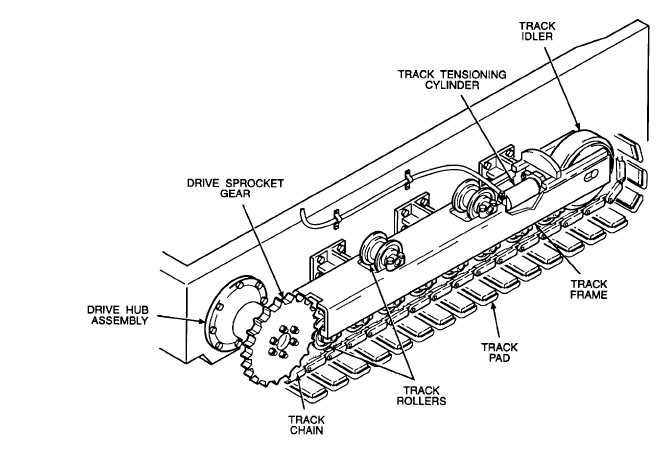

The chassis is an important part of a small excavator, especially when working in complex terrain, chassis maintenance is particularly critical:

- Check track tension: Make sure the track is not too loose or too tight, which can cause it to fall off, and too tight can accelerate wear.

- Clean the chassis: Clean the chassis after each operation, especially in muddy and dusty environments.

Financial issues: Manage excavator operating expenses

The operating expenses of an excavator include fuel costs, maintenance costs, labor costs, etc. Reasonable planning of these costs will help you reduce operating costs:

- Optimize fuel consumption: Keep the machine in optimal working condition and avoid wasting fuel.

- Reasonable scheduling: Arrange the working time reasonably to avoid long periods of idleness or excessive use.

Best tips for buying excavator chassis parts

When purchasing chassis parts, be sure to choose high-quality and adaptable products. It is recommended to consider the following aspects:

- Compatibility: Make sure the purchased parts are compatible with your excavator model.

- Quality assurance: Choose a reputable supplier to ensure that the purchased parts have a long service life and warranty service.

- Price comparison: Compare multiple suppliers to ensure that the purchased parts are competitively priced.

Other considerations before purchasing

When purchasing an excavator or its accessories, you should also consider the following factors:

- Equipment performance: Choose equipment that suits your engineering needs to avoid overinvestment.

- After-sales service: Find out whether the supplier provides complete after-sales support, such as technical consultation, equipment maintenance, etc.

- Equipment reliability and durability: In long-term use, the stability and durability of the equipment determine your return on investment.

Regular maintenance and careful care are the key to ensuring the efficient operation and extended service life of small excavators. By following the above maintenance guidelines, you can not only reduce equipment failures, but also improve work efficiency and reduce operating costs. Remember, only by paying attention to the long-term health of the equipment can you ensure the smooth progress of the project and obtain better economic benefits.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |