Excavators are versatile machines that play a vital role in various construction projects, from digging foundations to moving large volumes of soil. However, efficient operation requires knowledge of proper techniques, awareness of environmental factors, and adherence to safety standards. Whether you are a seasoned operator or a new excavator user, mastering these operation tips can enhance your productivity and safety on the job site.

GFM professional excavator undercarriage part manufacturer will delve into effective excavation techniques, provide tips for different operational environments, and emphasize key safety measures for excavator operators. Whether you’re dealing with muddy, rocky, or urban terrains, these tips will ensure you get the most out of your excavator.

Basic Excavator Operating Techniques

Before we dive into environmental considerations, it’s essential to understand the fundamental operating techniques:

- Smooth and Steady Movements: Always operate the excavator in a smooth, steady manner. Rapid, jerky movements can damage the machine and reduce operational efficiency.

- Use of the Hydraulic Controls: The joystick controls are crucial in managing the boom, arm, and bucket. Make sure to practice fine-tuned control for more precise digging, lifting, and dumping.

- Balancing the Load: When lifting heavy loads, always ensure the excavator’s arm is fully extended and that the machine is balanced to avoid tipping.

Operating in Different Terrains

Excavators often operate in a wide range of environments, each of which presents unique challenges. Here are tips for specific environments:

Working in Muddy or Wet Conditions

- Choose the Right Tracks: When working in wet or soft ground, ensure your excavator has wide tracks for better weight distribution and flotation.

- Avoid Overloading the Excavator: Muddy terrain can easily cause the machine to get stuck. Always avoid overloading and ensure the ground can support the machine.

- Use the Bucket Effectively: In wet conditions, it’s crucial to maintain slow and deliberate digging. Avoid digging in unstable areas to prevent sinking or tipping.

Operating on Rocky or Uneven Terrain

- Stabilize the Machine: Use the excavator’s outriggers or stabilizers to ensure the machine remains level. This is crucial when working on steep or uneven surfaces.

- Monitor the Excavator’s Position: Avoid placing the machine too close to large rocks or boulders. This will help prevent unnecessary stress on the excavator and reduce wear on components like the tracks.

- Fine-tune Digging: On rocky terrain, using a bucket with reinforced teeth will make your work much easier. Slow down your movements to ensure the bucket does not get damaged.

Excavation in Urban Areas

- Be Mindful of Surroundings: In crowded urban environments, always be aware of overhead power lines, underground utilities, and nearby structures.

- Precision is Key: Urban excavation often requires higher precision. Utilize the machine’s finer controls to avoid damaging surrounding areas.

- Limited Space Operations: In tight urban spaces, smaller, compact excavators may be necessary to maneuver. Make sure to plan your movements in advance to avoid obstructions.

Safety Considerations

Safe operation of an excavator is paramount to prevent accidents, injuries, and machine damage. Follow these safety tips:

- Operator Training: Ensure all operators are adequately trained in excavator handling, including operational controls and safety protocols.

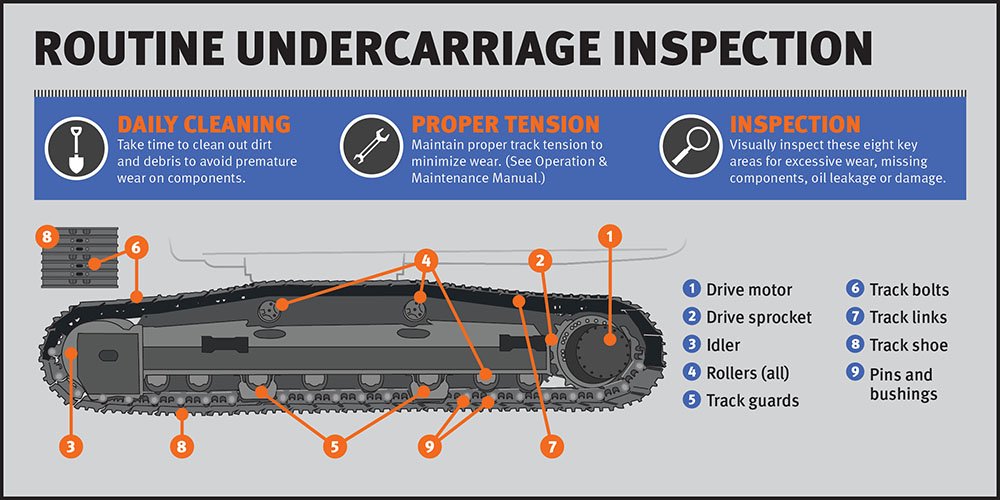

- Regular Machine Inspections: Conduct daily inspections before using the excavator. Check for any signs of wear and tear, fluid leaks, or malfunctioning components.

- Maintain Visibility: Always check your surroundings for other workers, machines, and obstacles. Use spotters if needed to ensure safe movements.

- Proper Seatbelt Use: Always wear a seatbelt while operating the excavator to minimize injury risk in case of sudden movements or tip-overs.

Maintenance Tips for Efficient Operation

Maintaining your excavator is essential for ensuring smooth and long-term operation. Regular maintenance tasks include:

- Lubrication: Ensure all moving parts, including the bucket, boom, and arm joints, are well-lubricated to reduce friction and wear.

- Check Hydraulic Fluids: Regularly monitor the hydraulic system for leaks and keep fluid levels at optimum levels to avoid pump failure.

- Monitor Tire and Track Wear: Inspect the tracks for signs of wear, especially if you’re working in harsh environments like rocky or wet terrains. Proper tire pressure can also contribute to better fuel efficiency and machine performance.

Mastering excavator operation is key to enhancing productivity, ensuring safety, and extending the machine’s lifespan. By following the tips outlined in this article and adapting to different work environments, operators can perform with greater efficiency and fewer setbacks. Always prioritize training, stay aware of your surroundings, and follow safety practices to avoid accidents.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Incorporating these operational techniques and environmental tips into your daily work routine will help ensure you operate your excavator safely and efficiently in any terrain. Proper machine handling and regular maintenance will also contribute to prolonged machine life and overall job site productivity. Always keep safety as your top priority, and continue honing your skills as an excavator operator.

By optimizing these techniques and integrating them with the use of high-quality excavator components like the ones provided by GFM, you can guarantee excellent performance on any job site.