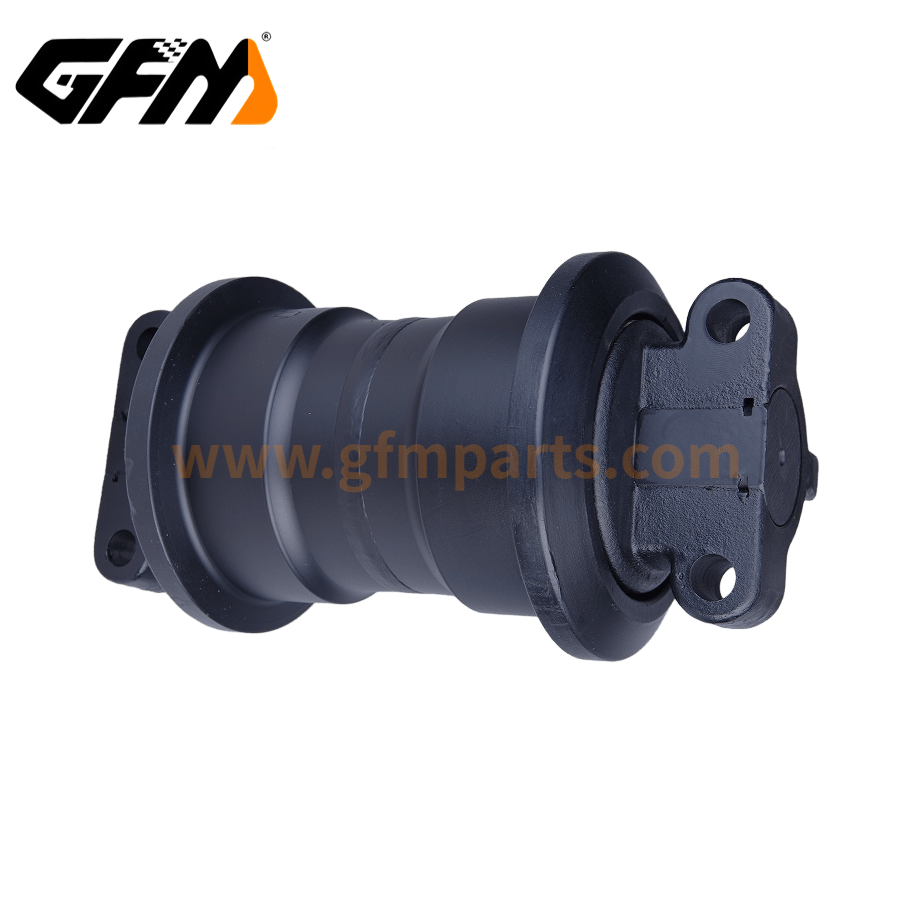

Sumitomo SH120-5 Excavator Track Roller

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

Share

Excavator bottom roller is important components to ensure smooth operation and extend the service life of the excavator during operation. As one of the key accessories of heavy machinery, track rollers play a supporting and guiding role in the crawler system of the excavator, and bear the huge pressure transmitted during operation. GFM Sumitomo SH120 excavator track roller are made of high-strength alloy steel materials, with excellent wear resistance and impact resistance, ensuring long-term and efficient operation even in complex environments.

Product advantage

High durability

Made of high-quality alloy steel, the track rollers are made of high-quality alloy steel to enhance the wear resistance and impact resistance of the track rollers. Under long-term working conditions, they can withstand heavy loads and high-intensity impacts and reduce the occurrence of failures.

Precision Manufacturing

Each track roller undergoes strict quality inspections and uses advanced manufacturing processes to ensure accurate dimensions and tight fit, reducing the risk of mechanical failures caused by defective accessories.

Reliable working performance

The track rollers are optimized in design to provide stable performance in various terrains and extreme climatic conditions, ensuring smoother and more efficient operation of the excavator.

Improve the life of the track system

High-quality track rollers effectively share the weight of the excavator, reduce track wear, extend the service life of the track system, and reduce maintenance costs.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator

- Packing: Standard Export Wooden Pallet

Features

- Premium Materials: Made with high-quality, wear-resistant steel to ensure a longer lifespan and consistent performance.

- Sealed and Lubricated: Designed with a sealed system that keeps the rollers lubricated, reduces friction, and prevents dirt or water from entering.

- Smooth and Stable Operation: Precision-engineered for balanced movement, improving the efficiency of your machinery.

- Fits Various Models: Offered in single-flange, double-flange, and center-flange designs to suit a wide range of excavators and bulldozers.

- Proven Toughness: Tested to handle heavy loads and operate effectively in rough environments, ensuring minimal downtime.

At GFM Factory, we are committed to delivering high-quality components that enhance the efficiency and longevity of your equipment. Our track rollers are designed to keep your machinery operating at peak performance, reducing downtime and maintenance costs.

For more information or to inquire about specific models, please contact us. GFM Factory – Your Reliable Parts Source!

Specifications

Product Models

Production Process

Packaging and Shipping

Factory Advantages

GFM track roller factory is a well-known high-standard production base in the industry, with advanced production lines and a complete quality control system. As a professional excavator parts manufacturer, we insist that each product must pass rigorous testing to ensure that it meets international quality standards. We have rich manufacturing experience and can provide customized production services according to customer needs to meet different market needs.

Advanced production technology

Our production plant is equipped with internationally leading production equipment and adopts automated manufacturing processes to ensure that the manufacturing process of each roller is refined.

Strict quality control

From raw material procurement to every process in the production process, we have strict quality management and testing standards to ensure that each roller can meet industry requirements.

Customized service

According to customer needs, we provide tailor-made services, and can provide customers with rollers that precisely meet the specifications to meet the needs of different projects.

Strong R&D capabilities

With a high-quality R&D team, we are committed to continuously optimizing product design, improving product performance, and ensuring that we always remain competitive in the market.

Reasons to choose us

Quality Guarantee

We are committed to providing high-quality Sumitomo SH120 excavator rollers. All products have passed strict quality inspections to ensure stability and durability.

Rich industry experience

With many years of experience in manufacturing excavator parts, we can provide professional technical support and after-sales service to help customers solve various problems.

Timely delivery

We guarantee on-time delivery and quick response to customer needs to ensure that customers have no worries during the project construction process.

Global market service

Our rollers have been exported to many countries and regions, and are deeply trusted and praised by customers around the world, ensuring that customers can enjoy high-quality products and services no matter where they are.

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- UNDERCARRIAGE

PC30-2 Bottom Roller Excavator Track Roller Manufacturer

- UNDERCARRIAGE

SY365 Excavator Track Link Assy Factory

- UNDERCARRIAGE

Excavator and Bulldozer Carrier Roller Manufacturers

- UNDERCARRIAGE

High Quality Excavator Track Chain Manufacturers