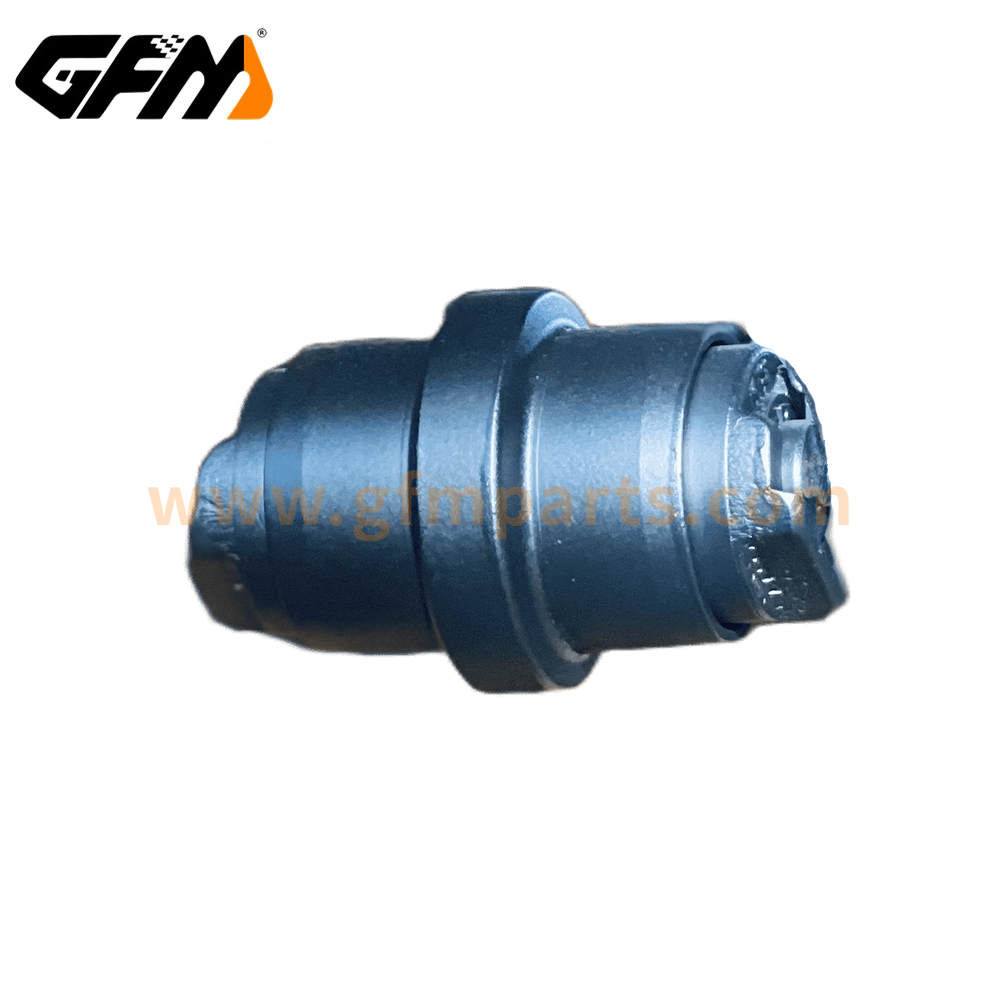

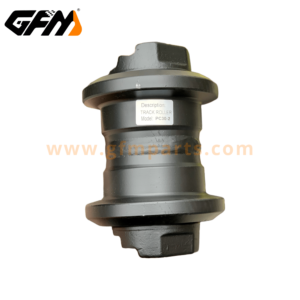

Mini Excavator Track Roller Manufacturer

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

Share

As a professional track roller manufacturer, we focus on the research and development and manufacturing of small excavator track rollers, and are committed to providing high-performance, durable and environmentally friendly product solutions for the construction machinery industry.

GFM mini excavator track roller is designed with internationally leading materials and advanced processes, and are tailored for small excavators under high load and long-term operation environments. Our products have undergone rigorous laboratory and field testing to ensure that they can stably exert super strong load-bearing capacity and wear resistance under various working conditions such as municipal engineering, construction, and mining. They are an ideal choice for customers to improve equipment stability and extend the life of the entire machine.

Product Features and Advantages

Material innovation and protection technology

- High-quality wear-resistant materials: high-strength alloy steel and special metallurgical technology are used to improve the impact resistance and wear resistance of the track rollers from the source, and excellent performance can be maintained even under extreme working conditions.

- Advanced surface treatment technology: through high-temperature heat treatment, cold plating and anti-corrosion coating processes, corrosion and fatigue damage can be effectively prevented, ensuring long-term stable operation of the product and reducing subsequent maintenance costs.

Precision manufacturing and intelligent production

- CNC precision machining: Introduce multi-axis CNC machine tools to achieve high-precision cutting and processing, ensuring that each track roller meets strict design dimensions and quality standards.

- Intelligent detection system: Laser measurement and three-coordinate detection technology are used throughout the process to monitor the processing process in real time, prevent defective products from entering the market, and ensure product consistency and reliability.

Scientific design and strict verification

- Optimized structural design: Use advanced CAD/FEA technology to perform mechanical simulation and optimization design on the product, fundamentally improving the load-bearing capacity and wear resistance of the track roller.

- Multiple working condition testing: The product has been verified by multiple experiments such as high temperature, high pressure, and fatigue resistance, strictly complies with international certification standards, and provides customers with reliable quality assurance.

Performance advantages and application value

- Ultra-high load-bearing capacity: The combination of optimized design and high-strength materials enables the product to have excellent load-bearing performance and can adapt to the high-intensity operation of small excavators in heavy-load working environments.

- Long-lasting and durable: Multiple protection technologies effectively extend the service life of the product, reduce the frequency of equipment maintenance, and save operating costs for customers.

- Stability guarantee: precise balance design and strict manufacturing process ensure that the product runs smoothly in long-term continuous work and reduce the risk of failure.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator

- Packing: Standard Export Wooden Pallet

Features

- Premium Materials: Made with high-quality, wear-resistant steel to ensure a longer lifespan and consistent performance.

- Sealed and Lubricated: Designed with a sealed system that keeps the rollers lubricated, reduces friction, and prevents dirt or water from entering.

- Smooth and Stable Operation: Precision-engineered for balanced movement, improving the efficiency of your machinery.

- Fits Various Models: Offered in single-flange, double-flange, and center-flange designs to suit a wide range of excavators and bulldozers.

- Proven Toughness: Tested to handle heavy loads and operate effectively in rough environments, ensuring minimal downtime.

At GFM Factory, we are committed to delivering high-quality components that enhance the efficiency and longevity of your equipment. Our track rollers are designed to keep your machinery operating at peak performance, reducing downtime and maintenance costs.

For more information or to inquire about specific models, please contact us. GFM Factory – Your Reliable Parts Source!

Specifications

Product Models

Production Process

Packaging and Shipping

Factory Advantages

GFM track roller factory is a well-known high-standard production base in the industry, with advanced production lines and a complete quality control system. As a professional excavator parts manufacturer, we insist that each product must pass rigorous testing to ensure that it meets international quality standards. We have rich manufacturing experience and can provide customized production services according to customer needs to meet different market needs.

Advanced production equipment and automated management

- World-class equipment: The factory is equipped with modern CNC machining centers and fully automated production lines to achieve efficient and accurate mass production.

- Intelligent management system: Introduce intelligent systems to monitor the production process throughout the process to ensure product quality and delivery timeliness.

Strict quality management system

- Full process quality inspection: from raw material procurement, production and processing to finished product testing, each process implements strict quality control, and the products pass international standard certification.

- Professional testing team: We have experienced quality inspection experts and use advanced testing equipment to ensure that each batch of products meets international high standards.

Strong R&D and technical support

- Professional R&D team: The R&D team composed of senior engineers and technical experts continues to carry out technological innovation and product upgrades, and constantly introduces new materials and new processes.

- Scientific research cooperation: We have established strategic cooperation relationships with many well-known scientific research institutions and technical institutions at home and abroad to jointly promote the development and progress of supporting wheel technology.

Contact Us

If you are looking for high-quality track rollers for mini excavator, GFM excavator accessories will be your best choice. Welcome to visit our official website or call the customer service hotline for more product details and technical support information. We look forward to working with you to create a better future!

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- UNDERCARRIAGE

Bobcat X320 Track Roller For Mini Excavators

- UNDERCARRIAGE

PC30-2 Bottom Roller Excavator Track Roller Manufacturer

- UNDERCARRIAGE

High Quality Excavator Track Idler Manufacturers

- UNDERCARRIAGE

High Quality Bottom Roller Manufacturer