Sumitomo SH210 Excavator Idler Roller

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

Share

In the field of construction machinery, the Sumitomo SH210 excavator is highly favored by users for its high performance and durability. GFM PARTS provides excavator idler roller designed for this model to provide the best working support for your equipment. Our products are not only strictly inspected by the process, but also integrated with advanced technology in the production process to ensure that each product has excellent durability and stability. At the same time, our factory has rich manufacturing experience and strong R&D capabilities, and can provide customized services according to customer needs, so that you can always maintain your advantage in the fierce competition.

- Precise design: Our idlers are tailored for Sumitomo SH210 excavators, and the parts are accurately matched. The design team conducts in-depth research on the use scenarios of the equipment to ensure that the idlers can withstand extreme working conditions and do not reduce performance due to long-term operation.

- Exquisite craftsmanship: Advanced equipment and strict process flow are used in the production process, and every step from the selection of raw materials to the final product is carefully inspected. Fine grinding and strict measurement ensure that each link meets high standards, so you can use it with confidence.

- Strong durability: The selection of high-quality materials combined with high-end processing technology ensures the firmness and wear resistance of the product. Whether in a high-intensity working environment or long-term work, it can maintain stable performance and extend the service life.

- Customized service: We are well aware that the needs of each customer are different. In addition to providing standard models, we can also customize products according to the specific conditions of the customer’s equipment. Whether it is size, material or surface treatment, it can meet your requirements.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator

- Packing: Standard Export Wooden Pallet

Features

- Durable:Built to withstand tough conditions for long-lasting performance.

- Perfect Fit: Designed for easy installation on various excavator and bulldozer models.

- Heavy Duty: Supports heavy loads for smooth and stable operation.

- Smooth & Quiet: Minimizes vibration for smoother movement and improved traction on all terrains.

- Low Maintenance: Self-lubricating for less upkeep and more uptime.

- Weather-Resistant: Performs well in any climate, resistant to rust and extreme temperatures.

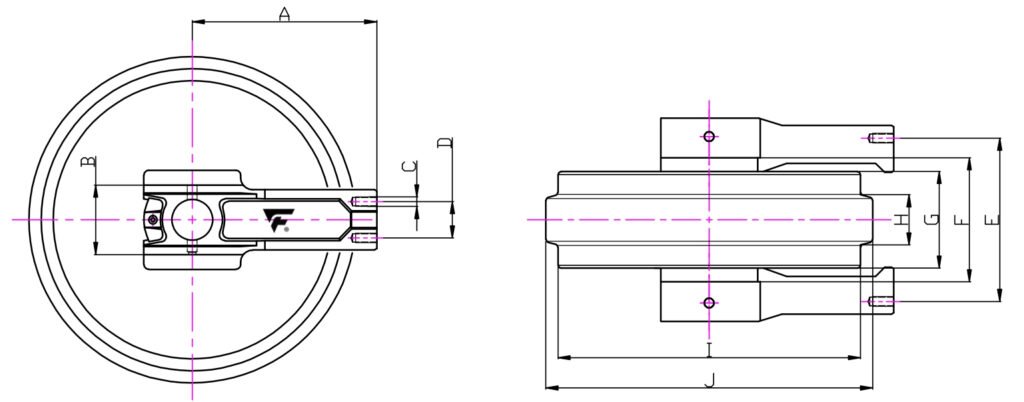

Specifications

Product Models

Production Process

From design to delivery, every process link of our products is strictly controlled to ensure product stability and durability. The following is an introduction to the basic process flow:

- Raw material inspection

- Select high-quality alloys and high-strength materials, and undergo strict chemical composition analysis and mechanical property testing.

- Clear test data records ensure that the materials fully meet the standard requirements.

- CNC machining and molding

- Use high-precision CNC machine tools for precision machining to ensure the dimensional accuracy of parts.

- The molding process has been repeatedly optimized to make the product surface smooth and avoid wear problems caused by machining defects.

- Surface treatment and heat treatment

- According to different application environments, select suitable surface treatment methods, such as spraying, galvanizing, etc., to improve the corrosion resistance of the product.

- The heat treatment process improves the internal structure of the material, increasing its hardness and wear resistance.

- Strict inspection and testing

- Each process has a special inspection link to ensure that unqualified products never leave the factory.

At the same time, through simulated on-site working condition testing, the idler wheel is ensured to perform well in actual use.

- Each process has a special inspection link to ensure that unqualified products never leave the factory.

Packaging and Shipping

Factory Advantages

GFM PARTS professional excavator idler manufacturer has many years of manufacturing experience and strong technical force, and all equipment has reached the international advanced level. The following is a brief introduction to our factory advantages:

- Advanced production equipment: The introduction of multiple internationally leading CNC machining centers and fully automatic testing equipment ensures that each product is precisely processed and tested.

- Quality management system: Strictly operate in accordance with the ISO quality system, and there are detailed records from raw material acceptance to finished product delivery to ensure that every link is traceable and product quality is based on evidence.

- Professional R&D team: After years of market precipitation and technical accumulation, we have an experienced and skilled R&D team. We can respond quickly to customer needs and continuously optimize product design and process flow.

- Strong customization capability: The factory can flexibly adjust the production line to undertake small and medium-sized batches and large-scale orders. Whether it is special materials, complex processes or unique designs, they can be customized according to needs.

Advantages of customized services

We always adhere to the principle of “customer first” and provide diversified customization solutions to help every customer achieve personalized needs. The customized services we provide mainly include:

- Product parameter customization: Through communication with customers, determine the specific parameters that are most suitable for the equipment to ensure perfect matching of equipment requirements.

- Design optimization: According to the on-site usage, our design experts will provide personalized improvement suggestions to further optimize product performance.

- Quick response: Whether it is drawing modification or new product development, we can respond to customer needs in the shortest time to ensure project progress.

- Full service support: From pre-sales consultation to after-sales installation and commissioning, we provide full-range technical support to ensure that customers have no worries during use.

This customized service not only improves the practicality of the product, but also greatly enhances customers’ trust and satisfaction with us, and establishes a long-term and stable cooperative relationship.

Friendly suggestions and practical tips

As an excavator parts factory, we not only provide high-quality products, but also hope to share some tips on using and maintaining idlers with customers to help you manage equipment more easily.

- Regular inspection: It is recommended to check the idler for obvious signs of wear or damage before and after each operation to detect problems in time and extend the life of the product.

- Proper installation: During the installation process, strictly follow the installation manual to ensure that all joints are firm to avoid affecting the operation of the equipment.

- Maintenance notes: Clean and lubricate the idler regularly to reduce the impact of dust and impurities on the friction surface and keep it running smoothly.

- Professional training: We regularly hold technical exchanges and training activities, invite customers to participate, and jointly discuss equipment maintenance methods and process improvement suggestions.

These practical tips can not only help you reduce the risk of failure in actual operations, but also provide strong guarantees for the long-term maintenance of equipment.

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- UNDERCARRIAGE

PC40-5 SF Excavator Track Roller Supplier

- UNDERCARRIAGE

Bulldozer Swamp Track Shoe Supplier

- UNDERCARRIAGE

Best Bulldozer Bottom Roller Factory

- UNDERCARRIAGE

High Quality Excavator Track Idler Manufacturers