Table of contents

- The role of bulldozer tracks and common wear types

- How to determine whether the bulldozer track can be repaired or must be replaced?

- Bulldozer track repair methods and tool recommendations

- Complete process and precautions for replacing bulldozer tracks

- Comparison of repair and replacement costs: How to choose the most cost-effective solution?

- How to extend the service life of bulldozer tracks: Complete analysis of maintenance techniques

- Common errors and experience sharing: Avoid further damage

Bulldozers are the main force in heavy engineering machinery, and the track system is indispensable for its ability to maneuver in complex terrain. We often see bulldozers advancing steadily on muddy, gravel, and even hillsides, which is inseparable from the stable support and strong traction provided by the tracks. However, frequent high-intensity operations also mean that one problem cannot be avoided: the tracks will wear out.

When the equipment begins to have problems such as track slippage, increased noise, and unstable operation, many operators and equipment managers will have a question: Can this worn bulldozer track shoe still be repaired? Should it be replaced with a new one? This question seems simple, but it actually involves multiple dimensions such as equipment life, safety, and cost of use.

The role of bulldozer tracks and common wear types

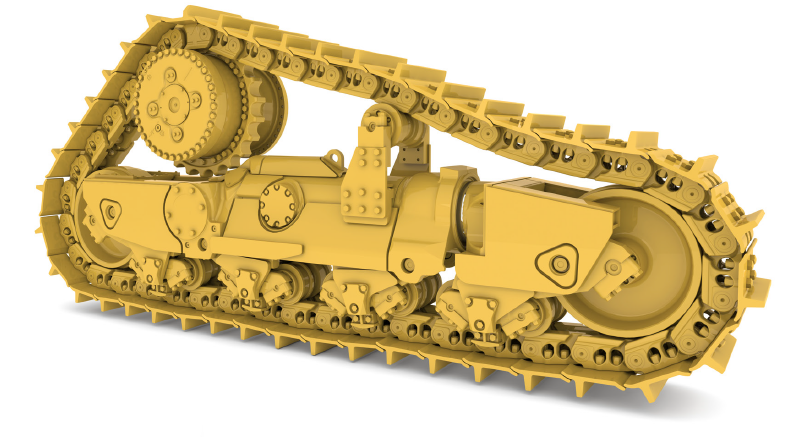

The track of a bulldozer is not a single component, but is composed of multiple sub-components such as track joints, pins, chain rails, and track shoes. The entire system distributes the weight of the bulldozer over a larger ground contact area through mechanisms such as supporting wheels, sprocket wheels, and drive wheels, thereby improving its passability and stability.

During long-term work, the track system faces a lot of impact, friction and sediment erosion. Common types of wear include:

- Chain track wear: The outer side of the chain track is worn thin, and asymmetric meshing occurs when it contacts the drive wheel.

- Loose pins and bushings: This causes excessive gaps between track segments, chain elongation, and affects running stability.

- Track plate wear or rupture: The plate surface is worn too thin or cracks extend.

- Loosening phenomenon: The chain loosens due to wear, causing the track to jump teeth and slip.

Different working environments have different effects on track wear:

- Muddy environment: Wet soil is easy to adhere, which increases the difficulty of cleaning and aggravates corrosion.

- Gravel area: High-intensity impact can easily cause metal fatigue and cracks.

- High temperature or cold areas: Material properties are easy to change, resulting in accelerated wear rhythm.

Are you looking for quality bulldozer parts at the best price? You have come to the right place. We are committed to providing excellent products and offering the best value to our customers. Your satisfaction is our motivation. Send an email to henry@gfmparts.com now and our bulldozer undercarriage experts will be happy to serve you.

How to determine whether the bulldozer track can be repaired or must be replaced?

When facing track wear, the first step is to determine whether it can be repaired, rather than replacing it immediately. Here are a few practical dimensions for judgment:

Wear threshold judgment:

Each track component has a usage limit when it is designed. For example:

- When the track pin gap is greater than 3mm, it is no longer recommended to continue using it.

- If the track plate thickness is less than 50% of the original thickness, the support force will be significantly reduced, and replacement should be considered.

- If the chain track height wear is greater than 40% of the original height, it needs to be stopped.

Is the structure damaged:

If the following problems are found, they usually cannot be solved by repair:

- Track segment breakage or large area cracks

- Pin stuck, broken

- Tooth mouth broken, causing tooth skipping

Use professional tools to detect:

Track gauge: measure the pin gap and pitch change to determine whether the chain is “extended”.

Vernier caliper: measure the track plate thickness, chain track height, etc.

Digital distance meter: used to determine the overall offset and tension state of the track.

Bulldozer track repair methods and tool recommendations

When the evaluation result is “still repairable”, you can extend the service life of the track in the following ways instead of rushing to replace it.

Track tension adjustment

When the chain slack is not due to severe wear, but due to loose tension springs or oil leakage, it can be adjusted through the tension cylinder.

Replacement of local parts

Replacement of single track plate: If a track plate is severely worn, the single plate can be replaced without replacing all of them.

Replacement of pins and bushings: Many equipment support pin replacement, and the cost is much lower than replacement of the entire chain.

Welding cracks and strengthening treatment

For small cracks in the chain track or plate body, carbon arc gouging + CO2 welding can be used for repair, supplemented by local heat treatment.

Recommended tools and equipment:

- Track tensioner

- Hydraulic pin puller

- Electric track segment grinder

- Wear gauge and track pitch gauge

Complete process and precautions for replacing bulldozer tracks

When the track wear is beyond the repairable range, it is necessary to consider replacing it. The following is the standard replacement process:

Replacement steps:

- Stop and clean: Park the equipment on a solid and flat surface and remove the mud and sand around the track.

- Release the track tensioning cylinder: Release the track pressure for easy disassembly.

- Use a hydraulic press to remove the pin: Disassemble section by section and remove the old track.

- Assemble the new track: Assemble section by section from the bottom, insert the pin and tighten it.

- Adjust the tension: Use the tensioning device to adjust to the specified pretension.

- Test run and inspection: Run for 30 minutes and check for abnormal noise and tooth jumping.

Precautions:

- It is recommended that at least two experienced technicians cooperate in the replacement process to ensure synchronization.

- During the disassembly and assembly process, avoid hard knocking to avoid damaging the roller or drive gear ring.

- All fasteners must meet the torque standard and be oiled to prevent rust.

Comparison of repair and replacement costs: How to choose the most cost-effective solution?

Whether to repair or replace often depends on the budget and operation requirements. The following is a comparison of common data (taking a medium-sized bulldozer as an example):

| Project | Repair | Replacement |

| Average cost | 3,000~8,000 | 30,000~50,000 |

| Extended service life | 6~12 months | 24~36 months |

| Downtime | 1~2 days | 2~4 days |

| Applicable situations | Minor wear and low task pressure | Severe wear or high-intensity operation |

How to extend the service life of bulldozer tracks: Complete analysis of maintenance techniques

Daily maintenance is the key to reducing wear and extending life. The following is the maintenance experience summarized by GFM for customers:

Regularly clean the track system: prevent eccentric wear caused by mud and sand inclusions.

- Check the tension: If the chain is too loose, it will jump teeth, and if it is too tight, it will accelerate wear.

- Avoid sharp turns: This will cause uneven force on the inner and outer tracks, causing abnormal wear of the track.

- Terrain adaptation operation: Drive straight and slow on hills, reduce speed on muddy ground, and operate with shock absorption on gravel ground.

- Lubricate and maintain the pin shaft: Especially for old models, regular oiling can greatly delay wear.

Daily maintenance methods for chassis components: Please refer to

Common errors and experience sharing: Avoid further damage

Many equipment damages are not caused by the quality of the track itself, but by improper operation or negligence of maintenance by users. The following are typical errors:

- Ignore the precursor signal: The chain jumps and abnormal noises frequently appear, but it is still used for a long time.

- Only replace the track plate without checking the track link: This will cause the new and old to be out of balance and accelerate the overall loss.

- On-site welding is not standard: temperature control and welding are not carried out, heat treatment is not in place, and new cracks are generated.

Common faults and repair methods of chassis components: Please refer to

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Whether the bulldozer track needs to be replaced depends on its wear state, operation requirements and maintenance conditions. Don’t replace it as soon as it’s old, and don’t use it as it’s broken. Through scientific testing, reasonable evaluation, appropriate repair or timely replacement, you can greatly extend the life of the equipment, control costs, and ensure construction safety.

As a professional bulldozer parts manufacturer, GFM provides a full set of chassis products including track links, track shoes, pin shaft assemblies, and provides customers with installation guidance and maintenance solutions. If you encounter any questions about the track in actual use, please feel free to contact our technical team. We are willing to be your trusted track solution expert.