Kobelco SK75 Excavator Idler Wheel Supply

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

In the day-to-day high-intensity operation of the excavator, the excavator idler wheel, as an indispensable component of the chassis system, plays an important role in supporting the track, guiding movement, and maintaining tension. Especially for small and medium-sized excavators such as Kobelco SK75, which are highly maneuverable and frequently used, they rely more on high-quality idlers to ensure smooth operation. As a idler assy excavator factory with 15 years of experience in manufacturing excavator parts, GFM is committed to providing customers with reliable, wear-resistant, and customizable front guide wheel products to truly achieve a win-win situation between performance and cost.

Tight fit, precise matching:

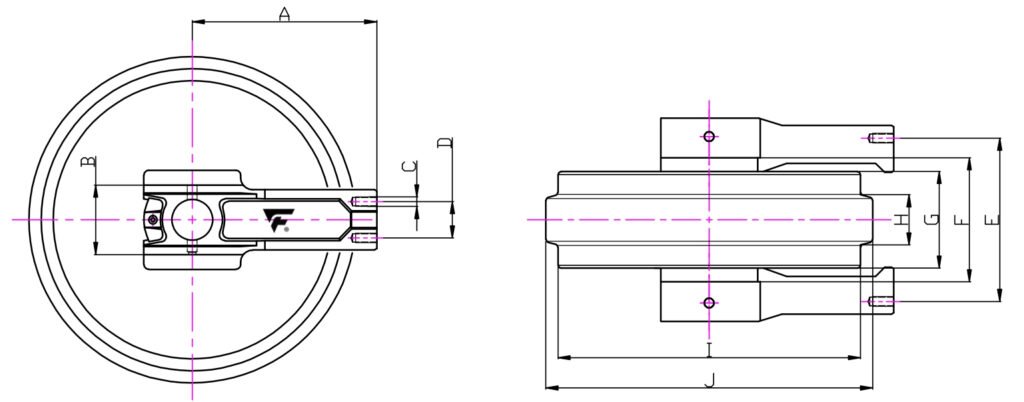

We reverse engineer and precision manufacture based on the original technical specifications of Kobelco SK75 (such as precise axle diameter, wheel width, bolt hole spacing, installation height and other core parameters). Each dimensional tolerance is controlled within a strict range (usually better than ±0.05mm), ensuring that it can perfectly replace the idler wheel on your original vehicle, fit in place like a puzzle, and restore the original smooth guidance and tensioning function of the track system.

Strong core, durability is the hard truth:

We insist on using high-quality alloy steel forging blanks. This material is inherently tougher and more impact-resistant than ordinary carbon steel. Then, it has to undergo the critical “tempering heat treatment + medium-frequency induction quenching” dual process. Simply put, it is to first make the entire component tough (hardness reaches HRC 28-32), and then “super harden the surface” of the key working surface that directly rubs against the track chain link (hardness soars to HRC 58-62, depth reaches 3-5mm).

Precision manufacturing, the key to smooth operation:

Good materials alone are not enough, precision determines success or failure. The inner hole (where the bearing is installed) and outer circle (where the track is guided) of the idler are completed on precision CNC lathes and grinders. This ensures:

The bearing can be installed steadily and tightly to avoid early damage.

The idler itself can rotate smoothly to minimize running resistance.

The track chain rolls smoothly on the idler surface, reducing abnormal wear and annoying noise. Every rotation is a silky smooth experience.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator

- Packing: Standard Export Wooden Pallet

Features

- Durable:Built to withstand tough conditions for long-lasting performance.

- Perfect Fit: Designed for easy installation on various excavator and bulldozer models.

- Heavy Duty: Supports heavy loads for smooth and stable operation.

- Smooth & Quiet: Minimizes vibration for smoother movement and improved traction on all terrains.

- Low Maintenance: Self-lubricating for less upkeep and more uptime.

- Weather-Resistant: Performs well in any climate, resistant to rust and extreme temperatures.

Specifications

Product Models

Production Process

From design to delivery, every process link of our products is strictly controlled to ensure product stability and durability. The following is an introduction to the basic process flow:

- Material refining

Select high-strength bearing steel, and improve the purity of the metal through refining, deoxidation and electroslag remelting processes

The chemical composition of the material is stable and can effectively resist fatigue cracks and impact loads - CNC machining

In the rough machining stage, a high-power CNC milling machine is used to quickly shape the blank and strictly control the allowance

In the fine machining stage, a multi-axis linkage CNC lathe and grinder are used to ensure the dimensional accuracy of the outer circle, inner hole and tooth surface - Heat treatment strengthening

The segmented quenching + low-temperature tempering process is adopted, and the hardness is uniform, with high wear resistance and toughness

Accurately monitor the quenching temperature and holding time to ensure that the internal structure of the parts is stable and crack-free - Surface treatment

Shot peening, phosphating, nitriding and other processes can be selected according to customer needs to further improve fatigue resistance

Under special working conditions, an environmentally friendly high-temperature resistant coating is provided to delay wear and corrosion - Strict testing and packaging

Comprehensive use of three-coordinate measuring instruments, roundness meters and hardness testers to ensure that key dimensions and mechanical properties meet the standards

Dust-proof and moisture-proof packaging, and customized packaging solutions can be provided according to the mode of transportation

Packaging and Shipping

Factory Advantages

Experience accumulation, focus on professionalism:

GFM has been focusing on the manufacture of engineering machinery accessories, especially track undercarriage system components (idlers, rollers, sprockets, drive gears, etc.) for more than 15 years. We have served thousands of end users and dealer partners around the world and accumulated valuable experience in handling various complex working conditions and customized needs.

Advanced equipment, solid quality foundation:

When you walk into our production workshop, you can see real “hard guys”:

- Large-tonnage forging equipment: Ensure that the blank is dense and defect-free inside, laying the foundation for high strength.

Fully automatic CNC machining center (CNC): Achieve stable and efficient processing of complex shapes and high-precision dimensions. - Precision grinder: Perform micron-level finishing on key mating surfaces to ensure smoothness and size.

- Computer-controlled heat treatment production line & medium frequency quenching equipment: Precisely control temperature, time, and cooling speed to ensure that material performance meets standards and is stable, and each furnace has records and traceability.

- Professional dynamic balancing tester: For high-speed rotating parts, we perform strict dynamic balancing correction to eliminate vibration hazards and run more smoothly and quietly.

Quality inspection is like a mountain, and data speaks:

Quality is not a slogan, but an action that runs through every step. From spectral analysis of incoming raw materials (to ensure that the material composition is qualified), to 100% online detection of dimensions during processing, to piece-by-piece hardness testing after heat treatment, and high-precision three-coordinate measurement (CMM) sampling of finished products, we have built multiple lines of defense. The pass rate of key dimensions and performance parameters has been stable for a long time at more than 99.5%, which is the source of our confidence. All test data are recorded and archived to ensure traceability.

REQUEST A QUOTE NOW

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- UNDERCARRIAGE

Sumitomo SH200 Excavator Track Idler Roller

- UNDERCARRIAGE

Front Idler Bulldozer Komatsu D60 Bulldozer Idler

- UNDERCARRIAGE

Excavator and Bulldozer Idler Wheel Manufacturers

- UNDERCARRIAGE

High Quality Excavator Track Idler Manufacturers