Bulldozers are the “tough guys” among construction machinery. They work in various extreme environments: from soft soil to hard rocks, from sun-bathed construction sites to cold plateaus, they bear heavy loads and friction continuously. Behind all these high-intensity tasks, the bulldozer tracks bear the weight of the entire equipment and are one of the key components to ensure traction and stability.

However, the use environment of the tracks determines that they are more susceptible to wear than other mechanical parts. If you do not pay attention to daily use and maintenance, even newly installed high-quality tracks may become loose, broken, chain stuck, gear jump, etc. in a short period of time. The consequences of this not only affect construction efficiency, but may even cause shutdowns and major losses.

So, can bulldozer tracks really only be “replaced when they are broken”? Actually not. As long as you follow scientific operating habits, do daily cleaning and maintenance, and combine the support of professional manufacturers, you can greatly extend the service life of the tracks and reduce the total operating costs.

This article will provide you with a practical guide to extend the life of the track from the aspects of driving operation, maintenance habits, working condition selection, and parts purchase. Combined with GFM’s years of practical experience and technical achievements, it will help you maximize the efficiency of bulldozer equipment.

Table of contents

- Correct operation is the first step: driving habits directly affect the life of the track

- Regular cleaning and lubrication: simple actions greatly extend the life of the track

- Inspection and maintenance must be done in place: from tension to wear conditions, nothing can be ignored

- Avoid operation in extreme environments: the influence of terrain, weather and operation methods

- Select high-quality parts and accessories: the material and manufacturing process of the track are crucial

- GFM bulldozer track solution: technical and service advantages of professional manufacturers

Correct operation is the first step: driving habits directly affect the life of the track

The first step to extend the life of the track is not some advanced technology, but to start with daily driving habits.

Avoid frequent sharp turns and “turning around in place”

The steering principle of the bulldozer track is different from that of the tire. It relies on “differential steering” – that is, turning by slowing down or even reversing one side of the track. If the driver frequently makes sharp turns in place, especially on dry and hard ground or gravel areas, one side of the track will be forced to rub against the ground, thereby increasing the wear of the track chain, track pins, chain links and even sprocket wheels.

Suggestions:

- When working conditions permit, try to use large radius curves instead of turning in place.

- Backing up slightly before turning can reduce the pull on the track chain links.

- Learn to use slopes or mounds to assist natural turning.

Control the operation speed and load intensity

In order to rush the work, many on-site operators will frequently switch the bulldozer to high gear or overload it. This not only increases the engine load, but also poses a threat to the track system, especially high-speed collisions cause uneven force on the track, which is more likely to cause local breakage or chain jams.

Recommendations:

- Control the speed, especially in areas with many obstacles or potholes.

- Slope operations should be pushed slowly from the slope uphill to avoid violent pushing on steep slopes.

- During the climbing process, the track should be kept straight as much as possible to reduce lateral shear force.

Reasonable use of bulldozing angle and direction

Many construction teams ignore the coordination between the bulldozer and the track direction. For example, side bulldozing, cross bulldozing and other operations will impose asymmetric loads on the track. This long-term accumulation of stress will cause eccentric wear of the chain track or displacement of the supporting wheel.

Recommendations:

- Try to keep the bucket parallel to the track, especially under heavy loads.

- Keep the load on both sides of the track balanced when bulldozing to avoid single-sided operation for too long.

- Adjust the bulldozer path alternately to make the track force more even.

Regular cleaning and lubrication: simple actions greatly extend the life of the track

After the bulldozer has been working for a long time, the track is often filled with dirt, gravel, crushed stone and other debris, forming “dry friction” and aggravating the wear between metals. The source of many equipment failures is “dirt”.

Cleaning the track: Don’t “clean until the machine stops”

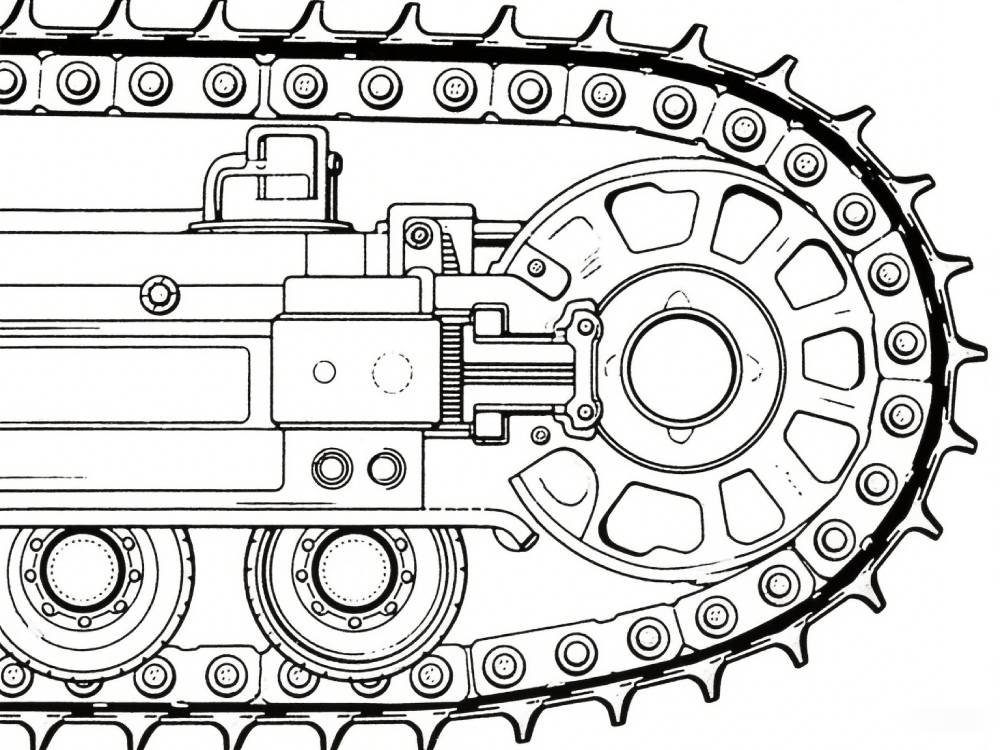

If the mud and sand adhere to the inside of the track for a long time, it will not only hinder the free movement of the chain links, but also easily affect the sprocket meshing and tensioning system, causing jamming, tooth skipping and even chain drop.

Recommendation:

- After the work is completed every day, clean the track with a high-pressure water gun or air gun.

- If it rains or wetlands, the mud should be cleared regularly in the middle to prevent the mud from agglomerating.

- Pay special attention to clearing the sand accumulated on the inside of the supporting wheel and the guide wheel.

Lubricate chain links and pins: rust prevention, anti-stuck, anti-breakage

The bulldozer track structure contains many high-strength metal contact surfaces, such as track pins, sleeves, chain links, etc. If these parts lack lubrication, metal fatigue will occur due to high-pressure friction.

Recommendation:

- Use industrial-grade grease (such as lithium-based grease, calcium-based grease).

- Check the lubrication status after every 100 hours of operation and add grease if necessary.

- After rainy and snowy days or wading operations, lubricating oil should be added immediately to prevent rust.

Inspection and maintenance must be done in place: from tension to wear conditions, nothing can be ignored

Maintenance is a systematic project, and it cannot be done “when you think of it”. The “tension” in the track system is one of the core elements to maintain structural stability.

Correct tension: neither too tight nor too loose

Overtight tracks will increase the load on the supporting wheels during operation, causing the drive bearing to fail prematurely; while overly loose tracks are prone to skipping teeth, chain drop, or even breakage.

Judgment criteria:

When the bulldozer is stopped, move the middle of the track up and down by hand or pry bar, and its verticality should be controlled between 30 and 50 mm. If it is too loose, tighten it, and if it is too tight, loosen it.

Tensioning method:

- Check the oil pressure of the tensioning cylinder (hydraulic tensioning type) or adjust the bolt length (mechanical tensioning type).

- After tensioning, run idle for two circles, and then confirm whether it is uniform.

- The tension force can be adjusted appropriately for different terrains (such as sand/gravel).

Regularly check the wear condition

Key parts:

- Track pins and sleeves: There should be no obvious grooves, and the chain link spacing should not be too large;

- Sprocket/supporting wheel: The wheel rim cannot be cracked or deformed, and there should be no deep marks on the wheel surface;

- Drive gear ring: If the wear exceeds 40% of the original tooth thickness, it should be replaced;

- Track plate bolts: Loose or falling off should be handled immediately.

Recommended frequency:

- Routine inspection once a week.

- Comprehensive maintenance every 500 hours.

- Pre-inspect 10 minutes before operation and summarize 15 minutes after operation to find small problems in time.

Avoid operation in extreme environments: the influence of terrain, weather and operation methods

Although the track is strong, no matter how strong the metal is, it cannot withstand the long-term erosion of the harsh environment.

Try to avoid long-term operation in the following environments:

- Mountainous areas with a lot of gravel: gravel is easy to get stuck in the chain links, scratch the surface or break the chain links;

- Muddy soft soil: easy to get stuck, forced driving will cause the track chain links to crack;

- Highly corrosive areas (such as saline-alkali land): metal is very easy to oxidize and rust after exposure;

- Continuous wading: mud and sand in the water adhere to the roller and the track, forming a grinding effect.

Coping strategies:

- Replace corrosion-resistant tracks or install sand covers.

- Dry or air-dry after operation.

- Reduce track idling and avoid “rubbing” operation in situ.

Select high-quality parts and accessories: the material and manufacturing process of the track are crucial

No matter how well maintained, if the track material is not up to standard, it will be difficult to use for a long time.

Material selection: not just “steel” is good

The tracks on the market are mainly divided into the following materials:

- Medium carbon alloy steel (such as 40MnB): high strength, good cost performance;

- High manganese steel: strong impact resistance, suitable for heavy load conditions;

- Wear-resistant alloy steel: specially used in harsh environments such as crushing and mining.

GFM’s track products use self-developed alloy steel formulas and undergo multiple heat treatment processes (such as quenching + tempering) to ensure a balance between hardness and toughness.

Process requirements: cooling accuracy and processing tolerance determine service life

- The hardness of the track pin must be above HRC55, which can effectively extend the friction life between the links.

- The processing accuracy error is less than ±0.05mm, which can ensure assembly stability.

- The bolts adopt a double thread design and an anti-loosening structure to increase operational safety.

Choose a high-quality manufacturer and judge its professionalism from its process certification, case customers, and material specifications.

GFM bulldozer track solution: technical and service advantages of professional manufacturers

As a company focusing on the manufacture of engineering machinery chassis parts, GFM has more than ten years of experience in track manufacturing, with an annual production capacity of hundreds of thousands of tracks, serving multiple global brands of equipment, such as Caterpillar, Komatsu, Shantui, etc.

GFM track core advantages:

- Strong OEM/ODM capabilities: chain link specifications, widths, and bolt spacing can be customized according to customer needs.

- High-precision processing equipment: CNC gear hobbing machine, heat treatment line, automatic assembly line.

- Stable quality: tensile test, wear test, and tension test are carried out before leaving the factory.

In addition, GFM provides after-sales technical training support, including installation guidance, tension adjustment demonstration, and regular maintenance training to help customers form a complete solution from use to maintenance.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

It is not difficult to extend the service life of bulldozer tracks. The difficult part is whether “maintenance” is truly integrated into the details of daily operations. From driving habits, cleaning and lubrication, to regular inspections and parts selection, every action may help you save the high cost of the next shutdown and maintenance.

GFM believes that “good equipment must be used well, and good equipment must be maintained well”. If you are looking for a long-term and reliable track partner, please contact us. We will provide you with more professional, durable and trustworthy track solutions.