Recently, a group of GFM’s key cooperative customers visited the GFM excavator chassis parts factory for a field visit. During this process, the customer learned in detail about GFM’s manufacturing capabilities, product quality control system and customized supporting services in the field of excavator undercarriage parts and engineering machinery parts, and expressed high trust and positive prospects for the long-term cooperation between the two parties.

Factory visit: In-depth understanding of GFM’s precision manufacturing strength

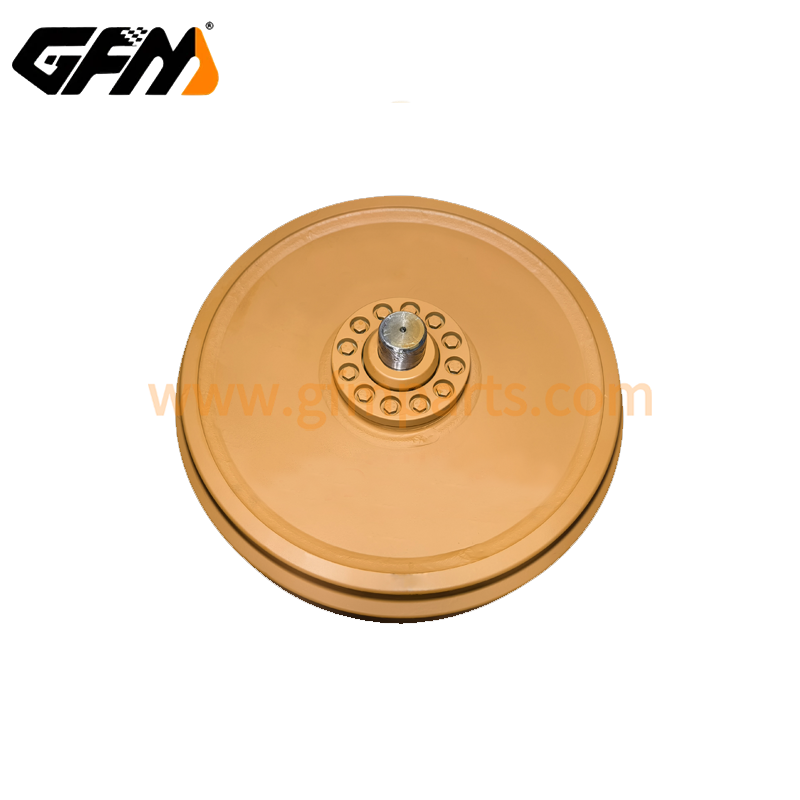

The customer first visited GFM’s modern production workshop and quality inspection center. As a excavator parts manufacturer focusing on core chassis parts such as excavator track assemblies, buckets, supporting wheels, guide wheels, sprockets, bucket teeth, etc., GFM is equipped with dozens of CNC machining centers, high-precision milling composite equipment and automated welding robots to ensure the dimensional accuracy and structural strength of each workpiece.

The customer focused on the following production areas:

➤ Precision machining workshop

Equipped with multiple CNC lathes and five-axis linkage machining centers to ensure high-precision matching and dimensional stability of key components such as sprocket teeth, supporting roller shafts, guide wheel bearing seats, etc. The processing tolerance can be controlled within ±0.02mm.

➤ Heat treatment and surface treatment center

GFM adopts heat treatment process to improve the impact resistance and wear resistance of components, especially suitable for construction environments of mines, heavy loads and high-frequency operations.

In terms of surface protection, the factory has a professional painting workshop. All accessories are treated by multiple sandblasting, electrophoresis and electrostatic powder spraying, and the corrosion resistance is more than 30% better than the industry standard.

➤ Welding and assembly line

Automated welding robots are used to ensure uniform and firm welding, effectively eliminating human differences. The crawler chain link assembly adopts special hydraulic pressing equipment, and the chain link coaxiality and preload are precisely controlled to ensure that the best operating state is achieved when leaving the factory.

In addition, customers highly praised the factory’s standardized operating procedures and ERP intelligent management system. GFM implements digital tracking from raw material storage to product delivery to ensure that the entire process is controllable, traceable and optimizable.

Professional team explanation: Demonstrating the advantages of technology research and development and engineering support

Accompanied by the foreign trade sales department, the customer learned about GFM’s capabilities in customized development. For different regions and different models of mainstream brand excavators such as Komatsu, Caterpillar, Hitachi, XCMG, LiuGong, etc., GFM can provide matching chassis models, and can optimize the structure or material according to the customer’s use environment (such as high humidity, high temperature, desert or mountainous area).

The customer has a deep understanding of GFM’s advantages in non-standard customization and OEM matching. GFM can develop chassis parts solutions tailored to the size differences of different models, the operating environment of different countries, and the specific requirements of customers for life and maintenance frequency.

For example:

For high humidity and high corrosion conditions, GFM adopts chrome-plated shaft core + thickened sealing ring design to significantly improve the sealing and life of the supporting wheels and guide wheels.

For the track plate requirements of customers in harsh areas, the tensile performance and deformation resistance of the plate body are improved by optimizing the material ratio.

In mining customer applications, GFM provides a combination of special impact-resistant sprockets and high-strength track links to ensure stability under high-frequency operations.

In addition, GFM’s quality department also demonstrated a complete set of testing processes, including raw material incoming spectral analysis, hardness testing, welding penetration testing, dimensional coordinate measurement, etc. Each batch of products is accompanied by a quality inspection report and a traceable numbering system is established to ensure that customers can purchase and use them with confidence.

The GFM engineering team demonstrated the company’s research and development capabilities in material wear-resistant treatment, heat treatment process control, coating anti-rust standardization, etc., so that customers can fully realize GFM’s manufacturing concept of “quality-oriented and customer-oriented”.

Customer feedback: fully affirm the cooperative relationship and express the intention to continue to expand the scale of cooperation

At the symposium after the visit, the customer representative said:

“This visit has made us more confident in cooperating with GFM. Your production line is professional, the process control is strict, and the delivery cycle is clear. You are a trustworthy partner. We will continue to expand our procurement plan and explore more customized project cooperation for chassis parts.”

For many years, GFM has always adhered to the service policy of “stable quality, fast response, and exclusive customization”, which not only won the trust of customers for long-term cooperation, but also established a good brand reputation in the international market. At present, GFM’s excavator parts have been exported to more than 30 countries and regions including Southeast Asia, Europe, the United States, the Middle East, and South America.

Advantages of GFM excavator parts factory

✅ Rich manufacturing experience: 14+ years of focus on the production of excavator chassis parts, mature technology.

✅ Complete categories: Covering crawler system accessories of mainstream models, supporting non-standard customization.

✅ Strict quality control system: Passed ISO 9001 certification, the qualified rate of finished products is as high as 99.8%.

✅ Controllable delivery time: Standard parts are always in stock, and urgent orders are responded to quickly.

✅ Trusted by global customers: Establish long-term cooperative relationships with dealers, repairers, and complete machine manufacturers in many countries.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

This customer visit is not only an on-site affirmation of GFM’s manufacturing strength, but also a deep blessing of the cooperative relationship. In the future, GFM will continue to uphold the service tenet of “customer first, quality first”, expand the international market, and provide global customers with better quality, reliable, and customized excavator parts solutions.

If you are also looking for a professional, efficient, and trustworthy excavator parts manufacturing partner, please contact us. GFM is willing to grow together with global customers and win the future together.