Wholesale Komatsu PC800 Excavator Carrier Roller 195-30-00580/KM2160

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

Share

In the high-intensity working environment of the excavator, the excavator carrier roller is one of the core components that supports the crawler and guides its smooth operation. Its quality directly affects the durability and stability of the whole machine’s walking system. GFM provides special top roller for large excavators suitable for the Komatsu PC800 model. It adopts high-strength forged steel material and precision heat treatment process to ensure excellent load-bearing performance and service life, which is an ideal choice for heavy-duty construction environments.

This carrier roller is specially adapted for Komatsu PC800 heavy excavators and has the following key performance characteristics:

Accurately match the original factory standards: the size, axis, hole spacing, and installation interface fully meet the original specifications of Komatsu, ensuring one-click replacement without additional modification.

Wear-resistant steel forged body: The whole body is made of 50Mn or 40Mn2 high-quality alloy steel, which has been forged and tempered for multiple times, and has strong impact resistance. It is especially suitable for high-impact environments such as rock conditions, mining, and crushing operations.

High-frequency quenching process: The wheel rim surface is treated with high-frequency induction quenching, and the hardness can reach HRC52-58, which effectively delays wear and significantly extends the service life.

Thickened wall design: The wheel body is thicker and stronger than conventional rollers, effectively supports the track chain and the weight of the whole machine, and runs more stably.

Double oil seal protection structure: imported double-channel floating seals are used to isolate dust and sand intrusion, and the internal lubricating oil is extremely sealed to ensure long-term maintenance-free operation.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Bulldozer or Crawler Tractor

- Packing: Standard Export Wooden Pallet

Features

- Long-Lasting Durability: Crafted from high-grade, wear-resistant steel for maximum strength and extended lifespan.

- Sealed and Lubricated: Fully sealed design keeps out dirt, water, and contaminants, minimizing wear and maintenance.

- Smooth Operation: Precision-engineered to provide efficient and stable support for the upper portion of the track.

- Corrosion Resistance: Corrosion-resistant surface treatments ensure reliable operation in harsh environments.

- Fits Various Models: Designed to fit a wide range of excavator and bulldozer models for various applications.

- Proven Toughness: Tested to perform reliably under extreme conditions, reducing downtime and increasing productivity.

At GFM Factory, our carrier rollers are built to optimize your machinery’s performance, ensuring smoother track operations and extended equipment life.

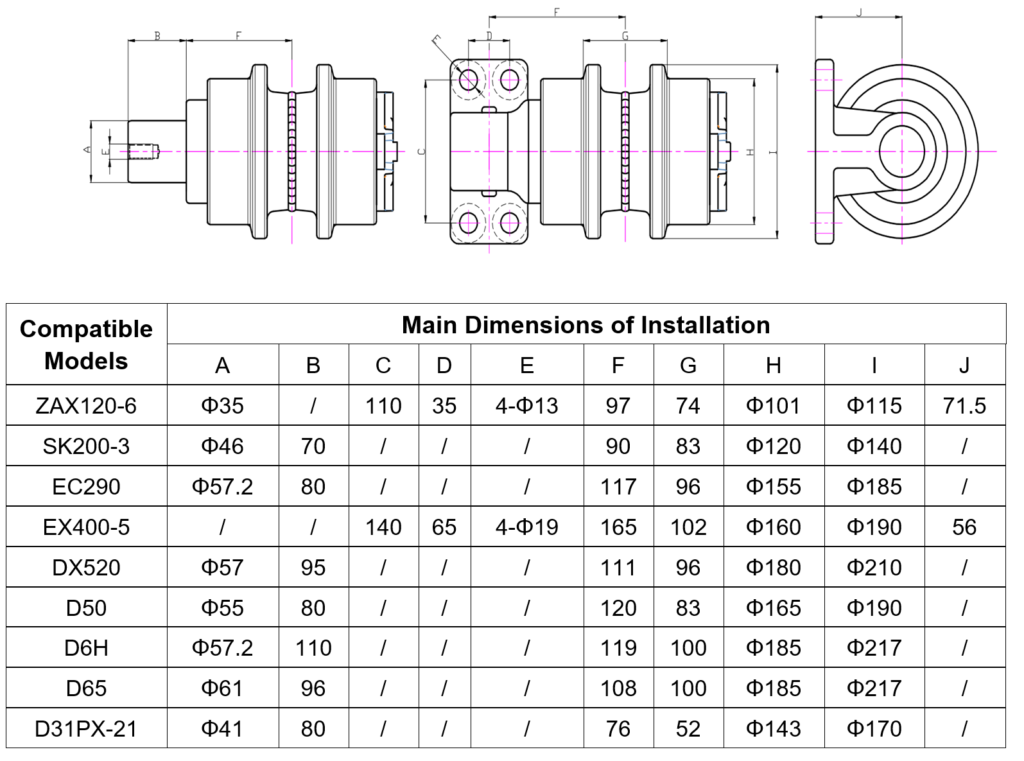

Product Models

Production Process

The production process is divided into four stages: raw material selection, CNC machining, surface treatment and final inspection. Each link is monitored by professionals to ensure that the process is smooth and without omissions.

- Raw material selection: Strictly select qualified suppliers to ensure that the materials are safe and environmentally friendly.

- CNC machining: High-precision equipment monitors dimensional errors in real time to ensure product consistency.

- Surface treatment: Use environmentally friendly technology to improve durability and appearance.

- Final inspection: Each product undergoes multiple tests before leaving the factory to ensure zero defects.

Through this rigorous process, we can provide customers with stable and reliable products, reflecting professional knowledge and technical strength.

Packaging and Shipping

Factory Advantages

As an excavator carrier roller factory with many years of deep cultivation in the industry, GFM has rich experience in the production of excavator undercarriage parts and perfect industrial chain supporting capabilities:

- Modernized machining center: equipped with vertical machining center, CNC lathe, CNC milling machine and other advanced equipment to support large-scale and precision machining tasks.

- Annual production capacity of one million wheels: with annual production capacity of more than 1 million wheels of various models, serving hundreds of OEMs and parts dealers around the world.

- Passed ISO9001 and CE certification: full process quality system management, all factory products can provide quality traceability and material reports.

- Rich adaptation model library: adapted to Komatsu, Caterpillar, Hitachi, Doosan, Hyundai, Volvo and many other brands.

- Global customer cooperation cases: At present, the products have been exported to more than 50 countries including Europe, America, the Middle East, Southeast Asia, Latin America, etc., and are well received by customers.

Customized service: meet your personalized needs

GFM not only provides standardized upper roller excavator products, but also supports OEM & ODM customized services to help customers achieve higher adaptability, stronger performance, and better cost-effectiveness:

- Support drawing sample customization: can quickly develop molds according to the drawings or samples provided by customers, and customize exclusive sizes and structures.

- Personalized brand service: can laser engrave customer brand LOGO, packaging labels, corporate identification colors to enhance brand recognition.

- Multi-specification batch support: support delivery from small batch to large batch, flexible delivery time, meet the requirements of engineering project cycle.

- Professional after-sales response mechanism: equipped with overseas technical service team, provide technical guidance, after-sales tracking and fast delivery of spare parts.

Welcome to contact us at any time to get a quote or technical information, GFM looks forward to becoming your long-term and stable accessories partner.

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- UNDERCARRIAGE

Mini Excavator Carrier Roller Manufacturers

- UNDERCARRIAGE

Bulldozer Swamp Track Shoe Supplier

- UNDERCARRIAGE

Best Bulldozer Bottom Roller Factory

- UNDERCARRIAGE

High Quality Bottom Roller Manufacturer