Kubota Mini Excavator U15 Idler

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

Share

GFM’s Kubota Mini Excavator U15 Idler is designed specifically for this compact model. It is made from high-strength forged steel and enhanced through heat treatment to withstand wear and tear in diverse jobsite conditions.

- Precision Fit: Engineered according to Kubota’s original parameters to ensure exact fitment with the track system—no further adjustment needed.

- Wear & Corrosion Resistance: Treated with anti-rust and heat-resistant processes for extended service life in muddy, rocky, or humid environments.

- Reinforced Structure: A robust internal design absorbs impact and reduces vibration during intense operations.

- Quiet Operation: Uses sealed low-noise bearings to maintain a smooth and quiet working experience.

This idler is also compatible with other mini excavator models of similar size and is widely recognized by clients from overseas markets.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator

- Packing: Standard Export Wooden Pallet

Features

- Durable:Built to withstand tough conditions for long-lasting performance.

- Perfect Fit: Designed for easy installation on various excavator and bulldozer models.

- Heavy Duty: Supports heavy loads for smooth and stable operation.

- Smooth & Quiet: Minimizes vibration for smoother movement and improved traction on all terrains.

- Low Maintenance: Self-lubricating for less upkeep and more uptime.

- Weather-Resistant: Performs well in any climate, resistant to rust and extreme temperatures.

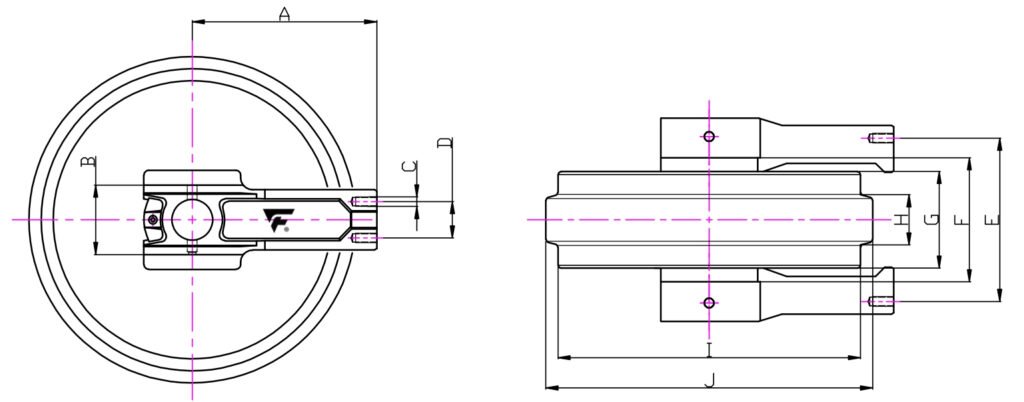

Specifications

Product Models

Production Process

From design to delivery, every process link of our products is strictly controlled to ensure product stability and durability. The following is an introduction to the basic process flow:

- Material refining

Select high-strength bearing steel, and improve the purity of the metal through refining, deoxidation and electroslag remelting processes

The chemical composition of the material is stable and can effectively resist fatigue cracks and impact loads - CNC machining

In the rough machining stage, a high-power CNC milling machine is used to quickly shape the blank and strictly control the allowance

In the fine machining stage, a multi-axis linkage CNC lathe and grinder are used to ensure the dimensional accuracy of the outer circle, inner hole and tooth surface - Heat treatment strengthening

The segmented quenching + low-temperature tempering process is adopted, and the hardness is uniform, with high wear resistance and toughness

Accurately monitor the quenching temperature and holding time to ensure that the internal structure of the parts is stable and crack-free - Surface treatment

Shot peening, phosphating, nitriding and other processes can be selected according to customer needs to further improve fatigue resistance

Under special working conditions, an environmentally friendly high-temperature resistant coating is provided to delay wear and corrosion - Strict testing and packaging

Comprehensive use of three-coordinate measuring instruments, roundness meters and hardness testers to ensure that key dimensions and mechanical properties meet the standards

Dust-proof and moisture-proof packaging, and customized packaging solutions can be provided according to the mode of transportation

Packaging and Shipping

Factory Advantages: Integrated Manufacturing & Service

With over 15 years of experience in undercarriage parts, GFM stands out among excavator idler manufacturers. We prioritize product quality and overall customer experience.

- Modern Facility: Over 10,000 sqm of manufacturing space, 60+ precision machines, and 5 auto production lines. Daily capacity exceeds 600 pieces.

- Strong R&D: A 15-person team with over 10 years of industry expertise.

- Global Customer Base: Our excavator track idler products are exported to 30+ countries including Europe, Southeast Asia, and the Middle East.

- Full Certifications: ISO 9001 quality system certified, CE and RoHS compliance for international markets.

- Flexible Delivery: Small-batch fast shipping, custom sampling, and flexible air/sea logistics reduce time and cost.

GFM is committed to being your long-term partner, offering reliable quality, punctual delivery, and flexible support. Whether you’re a startup brand or an established importer, we’re here to provide professional solutions for your Kubota Mini Excavator U15 Idler or other excavator track idler needs.

For more specifications, samples, or quotations, feel free to contact us or visit our website. GFM—Your trusted excavator parts expert.

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- UNDERCARRIAGE

John Deere 330 Excavator Track Idler

- UNDERCARRIAGE

Sumitomo SH210 Excavator Idler Roller

- UNDERCARRIAGE

New Holland E385C Idler On Excavator

- UNDERCARRIAGE

Track Idler Parts Komatsu D30 Bulldozer Idler