Table of contents

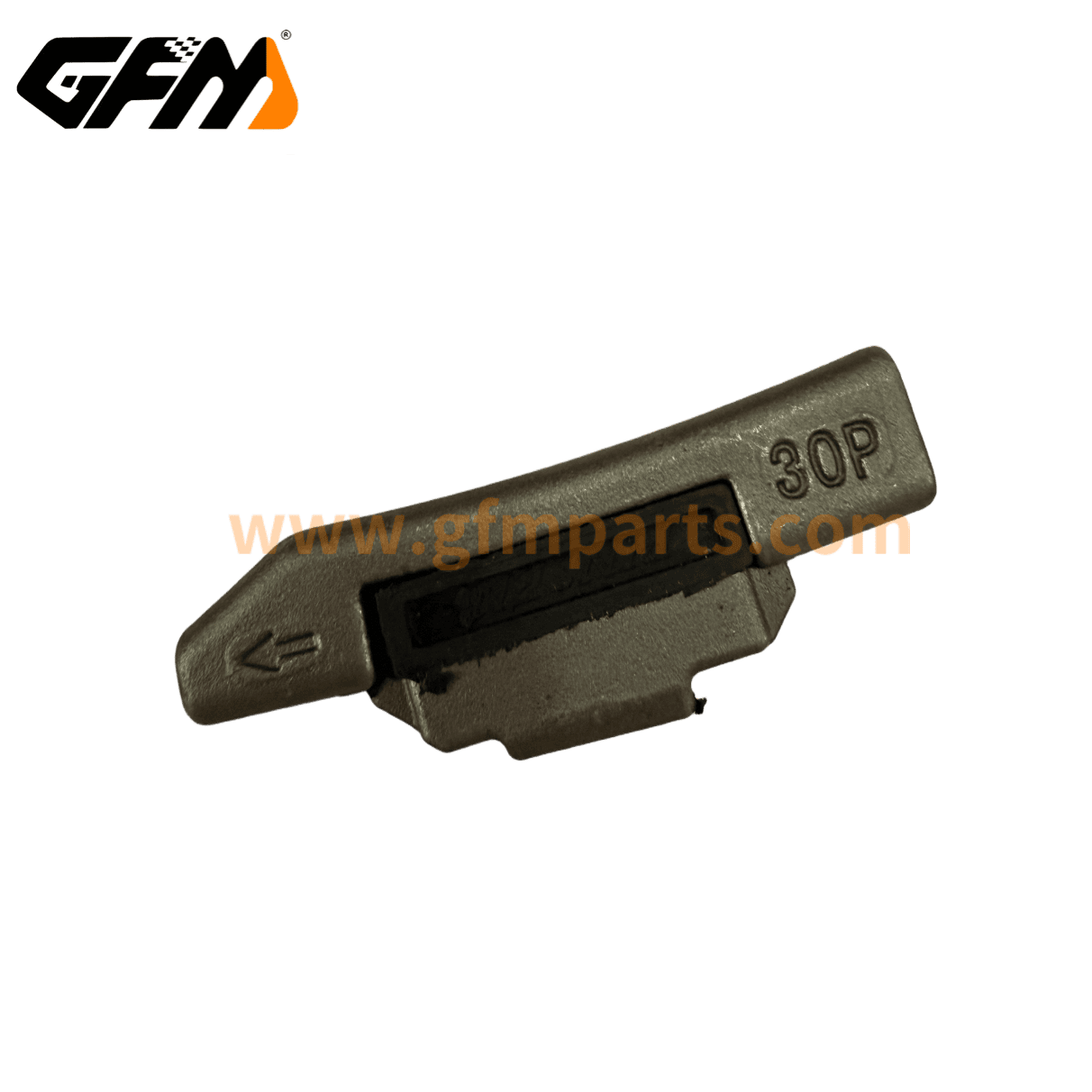

Basics of Excavator Bucket Pins

Excavator bucket pins are the critical components connecting the bucket to the arm of an excavator. They bear the enormous shear and bending forces generated during digging operations. A high-quality excavator bucket pin not only ensures operational efficiency but also prevents structural damage, reducing maintenance costs and downtime risks.

Core Functions of Bucket Pins

- Load Bearing: Bucket pins for excavator support the shear and bending forces of the bucket during digging, loading, and lifting.

- Structural Stability: They keep the bucket steady during hydraulic arm movements, ensuring operational safety.

- Power and Motion Transmission: Excavator bucket pins connect the bucket and arm, enabling smooth power transmission for lifting, lowering, and tilting operations.

Common Specifications and Materials

- Size Range: Small pins ~50–60 mm, medium ~60–70 mm, large ~70–80 mm in diameter; length generally 150–300 mm.

- Material Selection: High-strength alloy steel such as 42CrMo or SCM440 is commonly used, with quenching and tempering to improve hardness and toughness.

- Performance Advantages: High-strength alloy steel offers durability and resistance to bending or fracture under heavy loads.

High-quality excavator bucket pins ensure stability and reliability in a wide range of operating conditions, forming a cornerstone of mechanical safety.

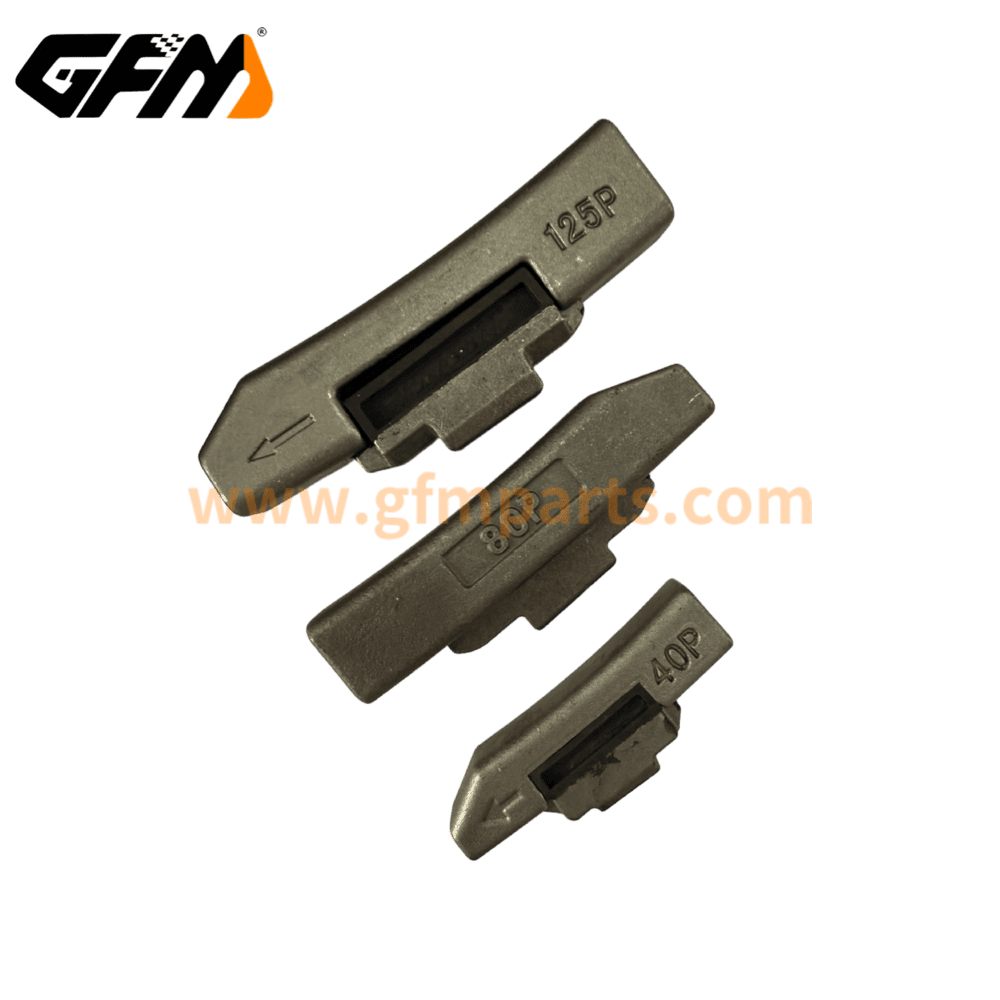

Main Types of Excavator Bucket Pins

Excavator bucket pins can be categorized by structure and operating conditions. Each type has unique advantages, suitable for different excavator models and work environments.

Classification by Structure

- Standard Pins – These have a straight, simple design, widely used across most excavator models. They are cost-effective, easy to replace, and require minimal maintenance, making them ideal for general earthmoving operations.

- Heavy-Duty Pins – Designed with larger diameters or thicker walls, these pins significantly increase load-bearing capacity and wear resistance. They are well-suited for high-impact working conditions such as mining, quarrying, and rock breaking.

- Locking Pins – Equipped with a locking mechanism to prevent loosening caused by vibration, they provide extra operational safety. Locking pins are recommended for long, continuous work cycles, though they may require specialized installation tools and have higher manufacturing costs.

Classification by Application

- Small Excavators (5–10 tons): pin diameter ~50–60 mm, for light earthwork.

- Medium Excavators (10–25 tons): diameter ~60–70 mm, for typical earth and stone work or urban construction.

- Large Excavators (25–50 tons): diameter ~70–80 mm, for mining, heavy-duty, or special conditions.

Choosing the appropriate bucket pin for excavator ensures efficient and stable operation under different working conditions.

Installation and Replacement Tips

Proper installation and replacement of excavator bucket pins are crucial for mechanical safety and longevity.

Preparation

- Tools: hydraulic press, manual wrenches, impact wrench, hammer, safety gloves, goggles.

- Safety Check: Ensure the arm is fully stationary and hydraulic pressure released.

- Clean Work Environment: Clean pin holes and surfaces to remove oil and debris.

Installation Steps

- Positioning: Align the bucket pin holes with the arm holes.

- Pin Fixation: Slowly push the pin into place, ensuring smooth installation.

- Lock Installation: Secure the pin with locking pins or retaining rings to prevent axial movement.

- Initial Check: Gently move the bucket to confirm there is no wobble or binding.

Common Mistakes and How to Avoid Them

- Misalignment: Uneven stress accelerates wear.

- Overtight Installation: Can cause stress concentration, increasing the risk of fracture.

- Lack of Lubrication: Increases friction, accelerates wear, and makes removal difficult.

Practical Tips

- Apply high-temperature grease or anti-wear oil before installation to reduce friction.

- Inspect tightness after the first week of operation and reinforce if necessary.

- Conduct early inspections of new pins to detect minor wear.

Wear Analysis of Bucket Pins

Excavator bucket pins are subject to wear under prolonged heavy-duty operation. Analyzing wear helps select suitable materials and treatment methods.

Common Types of Wear

- Surface Wear: Friction gradually thins contact surfaces.

- Tensile and Shear Damage: Micro-cracks may form under heavy load.

- Fracture: Overload or impact can cause pin breakage.

Factors Affecting Wear

- Material Choice: High-alloy steel plus heat treatment improves wear resistance and toughness.

- Heat Treatment: Quenching and tempering balance hardness and toughness, reducing brittleness.

- Working Environment: Sandy, rocky, or high-humidity conditions accelerate wear.

- Lubrication: Lack of lubrication increases friction and wear rate.

Methods to Improve Wear Resistance

- Surface Treatment: Carburizing or nitriding increases surface hardness.

- Pin Type Selection: Heavy-duty or locking pins reduce stress concentration.

- Regular Lubrication: Maintain the oil film on contact surfaces to lower wear rate.

- Timely Replacement: Replace pins showing signs of wear or cracks to prevent secondary damage.

Selection and Procurement Suggestions

Choosing the right bucket pin for excavator significantly affects operational efficiency and equipment lifespan.

Selection Principles

- Match Excavator Model: Refer to the machine manual or manufacturer specifications.

- Workload Requirement: Heavy-duty operations require thicker or high-strength alloy steel pins.

- Environmental Consideration: In sandy or rocky conditions, prioritize wear-treated excavator bucket pins.

Supplier Selection Criteria

- Experience and Certification: Long-term production experience, ISO9001 certified.

- Quality Control: Strict material testing and dimensional tolerance control.

- After-Sales Support: Technical support and replacement solutions to ensure uninterrupted operations.

Practical Procurement Tips

- Conduct small-batch trials under real working conditions.

- Establish long-term cooperation for consistent quality and stable supply.

- Consider material, treatment, and cost-effectiveness for optimal choice.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Although small, excavator bucket pins bear critical responsibilities in excavator operations. By scientifically selecting types, installing properly, monitoring wear, and working with reliable suppliers, operators can significantly improve efficiency, extend bucket pin for excavator lifespan, and reduce maintenance costs.

Applying these recommendations ensures safe, efficient excavation and highlights the importance of high-quality excavator bucket pins in both operational safety and economic performance.