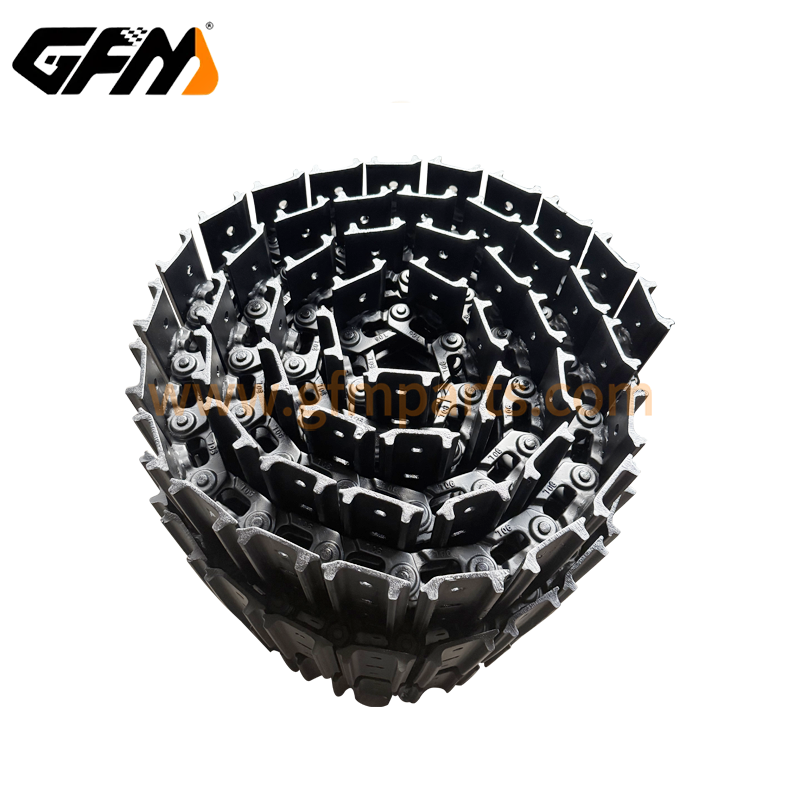

Wholesale PC20 PC30 EX30 Mini Excavator Track Chain Group

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

Share

GFM specializes in PC20, PC30, EX30 Mini Excavator Track Chain Group, providing high-quality and durable excavator track chains. Designed for mini excavators, these track assemblies offer stable support and excellent traction for construction sites, landscaping, or tight spaces.

- Durable Materials: Made of high-strength alloy steel with precise heat treatment, GFM excavator track chains are wear-resistant, impact-resistant, and long-lasting.

- Precision Design: Each chain plate and pin is strictly inspected to ensure tight fit and long-term reliability, reducing maintenance and repair costs.

- Compatibility: Tested to fit various mini excavator models for quick installation and stable operation.

- Easy Maintenance: Chains are simple to install and replace, with clear instructions for convenient daily upkeep.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator or Bulldozer

- Packing: Standard Export Wooden Pallet

Features

- Exceptional Durability: Made from premium materials to endure heavy-duty operations and resist wear over time.

- Perfect Fit: Engineered for precise alignment with excavator and bulldozer track systems, ensuring optimal performance.

- High Load Capacity: Designed to withstand intense workloads while maintaining strength and stability.

- Effortless Operation: Ensures smooth engagement with the track chain, reducing vibration and boosting efficiency.

- All-Weather Performance: Built to resist rust, moisture, and extreme temperatures, ensuring reliability in any environment.

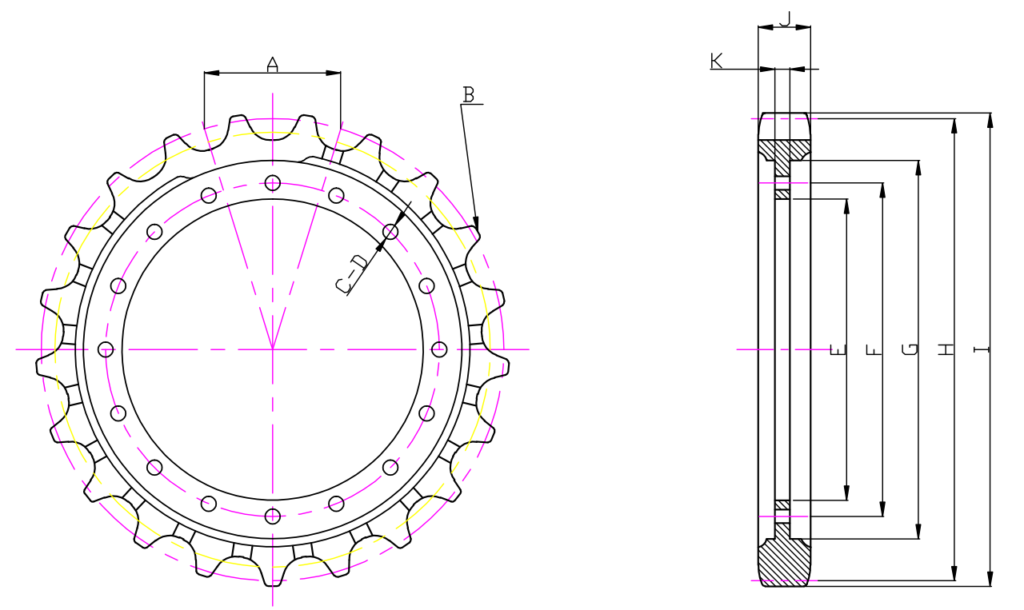

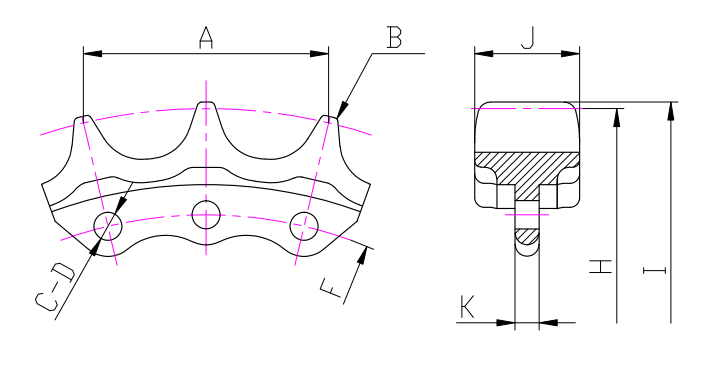

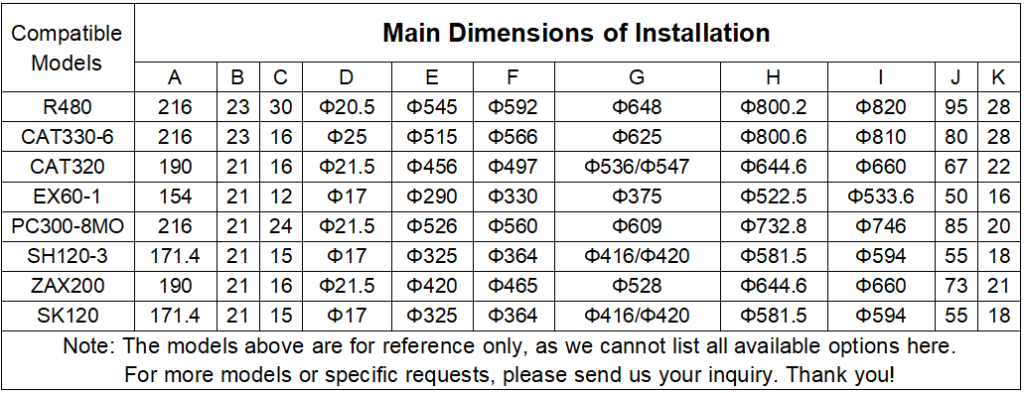

Specifications

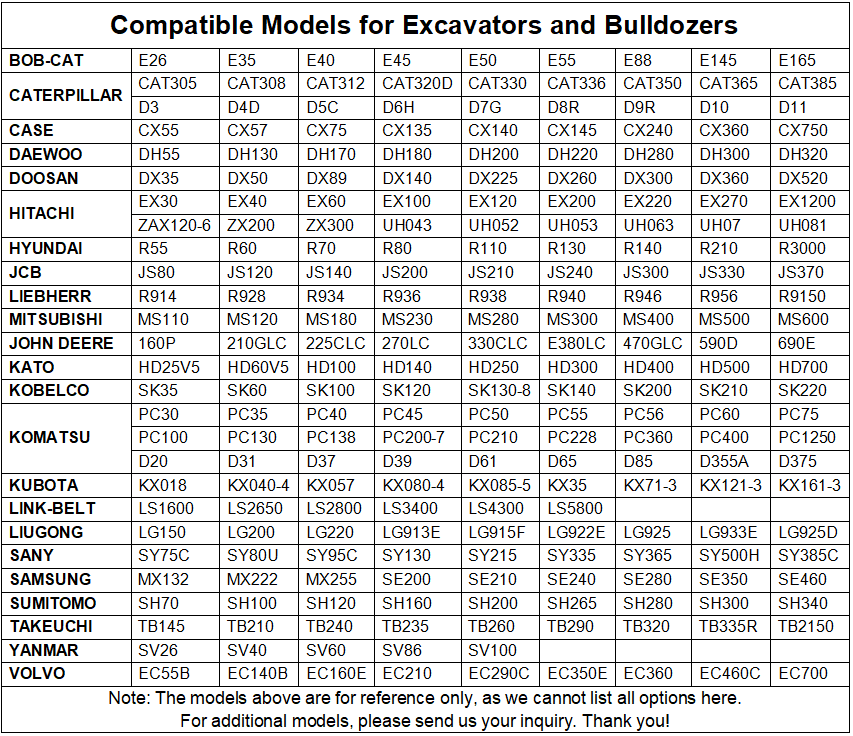

Product Models

Production Process

- Forging blank: high-quality alloy steel bars are selected for isothermal forging to ensure that the internal structure is dense and uniform.

- Heat treatment: first quenching and then tempering, and then temperature tempering to eliminate internal stress; the balance of hardness and toughness makes the sprocket less likely to crack under high torque environment.

- CNC machining: precise cutting is carried out through the five-axis linkage CNC machining center, and each tooth surface is repeatedly polished to ensure the tolerance range and surface finish.

- Surface strengthening: high-temperature nitriding or phosphating treatment, combined with shot peening to eliminate residual stress and improve fatigue life.

- Quality inspection: equipped with advanced inspection equipment such as three-coordinate, hardness tester, profilometer, etc., full inspection of multiple indicators such as size, hardness, surface quality, magnetic particle flaw detection, etc.

- Dynamic balance test: The assembly test bench simulates the operation of the actual vehicle, detects vibration and temperature rise, and ensures that the products shipped meet the use requirements 100%.

Packaging and Shipping

Factory Advantages

- Rich Manufacturing Experience: Since 2011, GFM has specialized in producing undercarriage parts for excavators and bulldozers, accumulating over 14 years of professional expertise. Our experience makes us a reliable excavator sprocket manufacturer, capable of supplying high-quality parts for diverse equipment models.

- Advanced Production Equipment: GFM’s factory features modern forging machines, automated processing equipment, and high-precision CNC machines, ensuring consistent machining accuracy and quality. Our production lines support both large-volume orders and urgent supply requests, making us a dependable excavator sprocket supplier.

- Strict Quality Control: Every part undergoes rigorous testing from raw material to final product, including dimensional checks, hardness testing, and load trials. GFM guarantees at least one year or 2,000 hours of quality assurance, reflecting our standards as a leading excavator sprocket manufacturer.

- Ample Stock & Fast Supply: We maintain extensive inventory covering most models and specifications, ensuring rapid delivery for bulk or emergency orders. This capability reinforces our position as a trusted excavator sprocket supplier for customers worldwide.

- Competitive Pricing & Global Trust: Supplying at direct factory prices, GFM combines reliable quality with competitive rates. Our customers trust us as both an excavator sprocket supplier and excavator sprocket manufacturer for durable, high-performance sprockets delivered on time.

- Comprehensive Customer Support: From part selection to after-sales consultation, GFM provides professional guidance to ensure optimal performance and satisfaction for all customers, strengthening our reputation as a reliable excavator sprocket supplier.

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- UNDERCARRIAGE

SY365 Excavator Track Link Assy Factory

- UNDERCARRIAGE

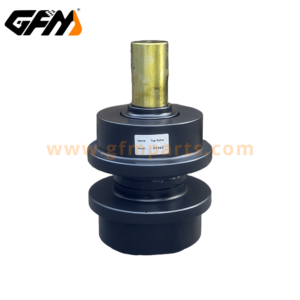

Wholesale Excavator Top Roller SY365

- UNDERCARRIAGE

Excavator and Bulldozer Idler Wheel Manufacturers

- UNDERCARRIAGE

High Quality Excavator Track Shoe Manufacturer