Table of contents

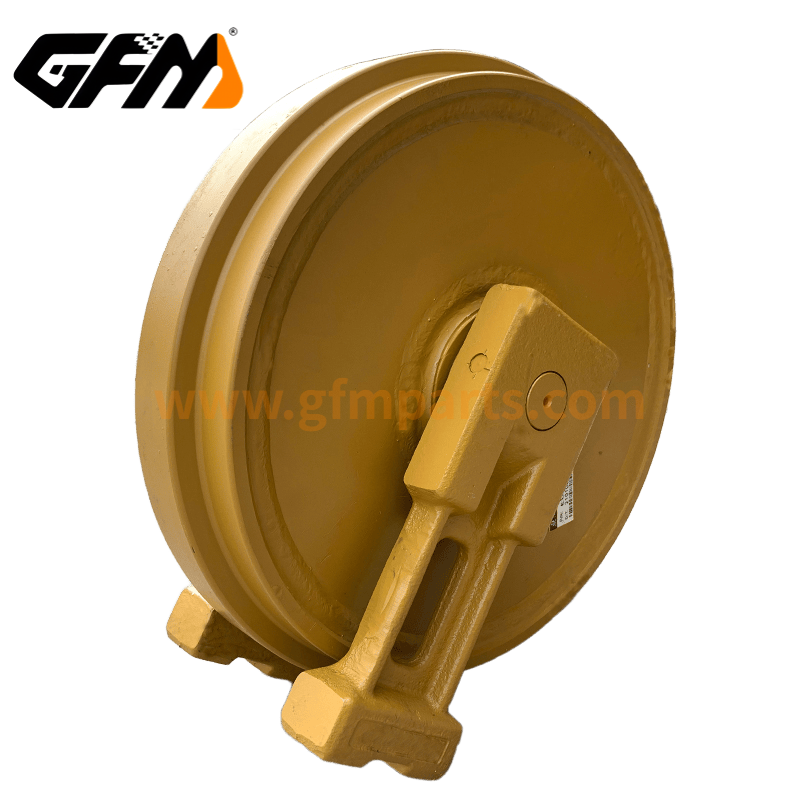

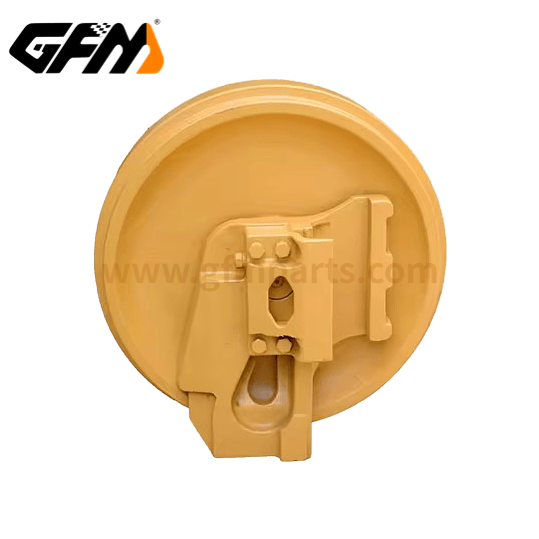

The Role and Value of Excavator Idlers

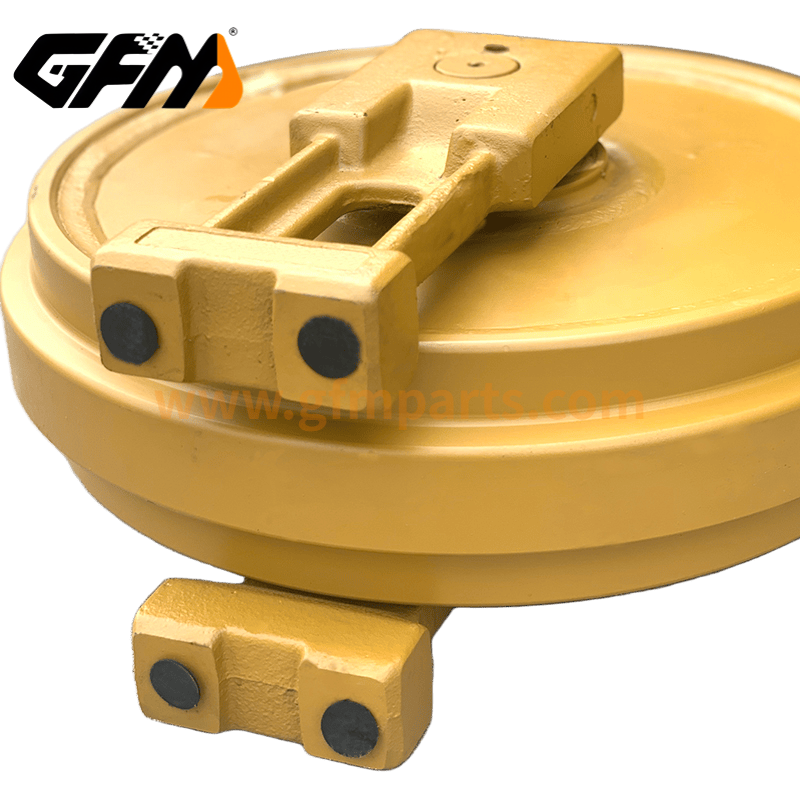

The idler for excavator is one of the most critical components of the undercarriage system. It not only determines machine stability and operating efficiency but also directly affects service life and maintenance costs. Its role and value can be summarized as follows:

- Support and Guiding Function: Positioned at the front of the track frame, the idler effectively guides the track to run in the correct path, preventing derailment and misalignment. This ensures stable operation even under harsh working conditions.

- Tensioning and Buffering: By working with the tensioning device, the idler maintains proper track tightness. This avoids slippage caused by looseness or excessive wear from over-tightening. At the same time, it provides buffering performance to reduce shock and impact on the undercarriage.

- Reduced Wear and Extended Service Life: High-quality excavator idlers are manufactured with alloy steel and advanced heat treatment technology. This ensures excellent wear resistance and impact strength, significantly reducing undercarriage wear and extending the overall machine lifespan.

- Improved Efficiency and Safety: A durable and reliable idler enhances machine balance and flexibility during heavy-duty operations, reducing breakdown rates, improving efficiency, and ensuring safer construction processes.

Clearly, the idler is not just a simple spare part but a key factor that determines excavator performance and long-term economic value.

GFM’s Strength and Development History

Founded in 2011, GFM has grown over 14 years into one of China’s leading excavator idler manufacturers. The company has focused on research, production, and distribution of undercarriage parts for excavators and bulldozers, building a solid reputation in both domestic and international markets.

- Production Base: A modern 20,000 m² factory equipped with 10 advanced production lines.

- Team Size: Over 180 employees, including skilled engineers and quality control experts to ensure precision at every step.

- Annual Capacity: More than 5,000 pieces of high-quality excavator idlers are manufactured each year, meeting large-scale global demand.

- Development Path: Since its founding, GFM has consistently invested in process upgrades, technical improvements, and market expansion, establishing itself as a strong player in the global construction machinery supply chain.

These solid achievements highlight GFM’s authority and professionalism in the field of idler for excavator manufacturing.

GFM’s Core Advantages in Excavator Idler Manufacturing

As a specialized excavator idler supplier, GFM stands out with a number of advantages that give it a leading edge in the industry:

- High-Quality Raw Materials: All idlers are produced using high-strength alloy steel, carefully inspected for hardness and toughness to guarantee durability.

- Advanced Manufacturing Process: CNC machining and quenching technologies are applied to achieve precision dimensions, optimal hardness, and superior performance.

- Strict Quality Control: Each idler undergoes multiple inspections, including hardness tests, metallographic analysis, and load simulations, ensuring compliance with international standards.

- Compatibility with Leading Brands: GFM’s idlers are designed to fit a wide range of excavators, including Komatsu, Caterpillar, Hitachi, Hyundai, Doosan, Sany, Volvo, and many others.

- Stable Production Capacity: With 10 production lines and standardized management, GFM ensures fast response to orders, reliable delivery times, and consistent quality.

These strengths have made GFM a preferred choice among global excavator idler manufacturers.

GFM’s Manufacturing Process and Quality Assurance

High-quality products are built on advanced manufacturing processes and strict quality assurance systems. GFM follows a refined production workflow:

- Precision Forging: Increases internal metal density, enhancing the idler’s strength and resistance to impact.

- CNC Machining: Guarantees dimensional accuracy and perfect fit within the undercarriage system.

- Heat Treatment: High-frequency quenching and tempering provide wear resistance and surface hardness, preventing early failures.

- Automatic Welding: Ensures uniform and robust weld seams for stronger structure integrity.

- Surface Protection: Shot blasting and anti-rust coating are applied to resist corrosion and extend service life.

- Complete Quality Testing: From raw material inspection to final delivery, every idler is strictly tested before leaving the factory.

This comprehensive process ensures that GFM idlers perform reliably even in the most demanding working conditions.

GFM’s Global Market and Customer Trust

GFM’s idlers and undercarriage parts are not only widely used in China but are also exported to international markets, serving clients across multiple continents.

- Export Reach: Products are shipped to countries including India, Russia, Brazil, Turkey, and the UAE, where demand for construction machinery parts is high.

- Customer Base: GFM supplies OEMs, construction contractors, and major spare parts distributors worldwide.

- Reputation: With stable quality, competitive prices, and timely delivery, GFM has earned long-term trust from international customers.

- After-Sales Support: The company provides full technical assistance and after-sales service to ensure seamless product use.

Thanks to its focus on reliability, compatibility, and efficiency, GFM has secured a solid reputation among global buyers seeking dependable idler for excavator solutions.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

As a professional excavator idler manufacturer in China, GFM has built its reputation on precision engineering, strict quality control, and years of manufacturing expertise. By focusing on durable materials, advanced heat treatment, and reliable performance, GFM ensures that every idler for excavator meets global standards. Choosing GFM means partnering with a trusted supplier that understands the demands of heavy machinery and consistently delivers components that maximize efficiency and longevity.