Table of contents

- Structure and Core Function of Excavator Sprocket Wheels

- Common Types and Application Scenarios of Excavator Sprockets

- Primary Causes of Sprocket Wear and Preventive Measures

- Determining the Timing for Sprocket Replacement and Operational Procedures

- Specialised Tools, Technical Methods and Safety Precautions

Structure and Core Function of Excavator Sprocket Wheels

The excavator sprocket wheel serves as a critical transmission component within the undercarriage system, directly determining both the traction force transmission of the tracks and the overall operational stability of the machine. Its design must not only meet stringent requirements for high strength and wear resistance but also ensure precise matching with the track pitch to achieve smooth and efficient operation.

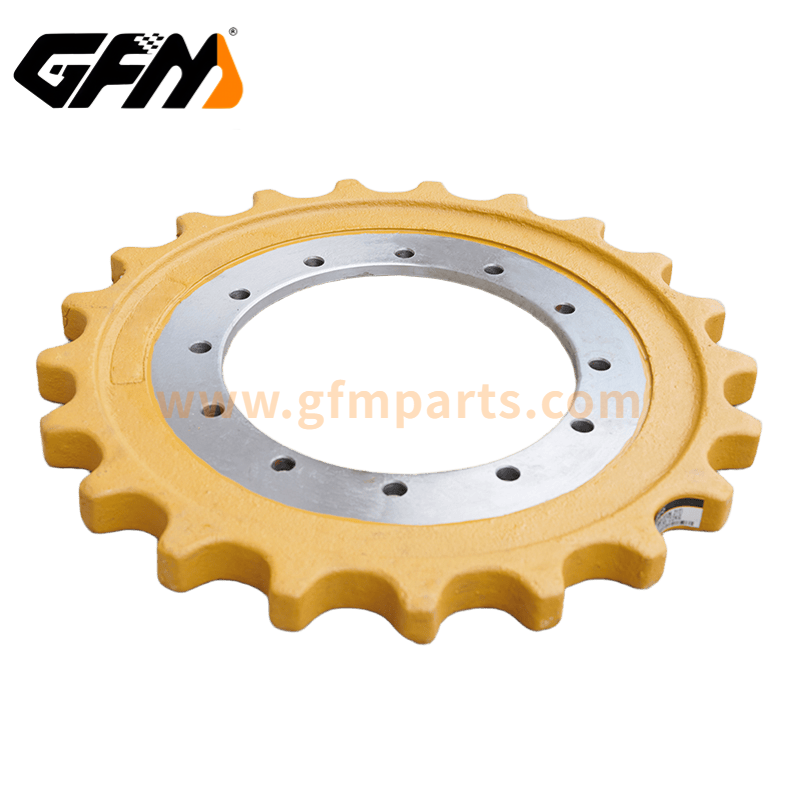

1. Basic Structure of the Sprocket Wheel

- Toothed Ring Section: Engages with the track link teeth, forming the operational core of the sprocket wheel. Typically manufactured from high-strength alloy steel and treated via through-hardening or induction hardening processes to enhance wear resistance.

- Wheel Body Section: Provides structural support, bearing the weight of the entire machine and transmitting impact forces. Requires high toughness and strength.

- Mounting Holes and Connection Points: Secure the sprocket to the final drive, ensuring stable power transmission.

2. Core functions

- Power Transmission: Converts torque from the engine via the final drive into traction force for the tracks, enabling machine movement.

- Load Bearing: Withstands impact loads and gravitational pressure generated during excavator operations, ensuring stable machine performance in complex working conditions.

- Wear Distribution: Through rational tooth profile design, ensures even distribution of meshing forces, reducing localised wear and extending the overall service life of both sprocket and track.

- Compatibility and Precision: The sprocket pitch must precisely match the track pitch. Failure to do so may result in poor meshing, track tooth skipping, or even breakage.

Common Types and Application Scenarios of Excavator Sprockets

Requirements for sprockets vary significantly across different operating conditions. Consequently, excavator sprocket manufacturers design and supply various specifications and types tailored to specific application scenarios.

- Standard Sprockets: Standard sprockets are typically employed in earthmoving, road construction, agricultural, and general engineering environments. Their tooth profile design prioritises stable meshing, offering moderate pricing and reasonable replacement intervals. For routine light-to-medium duty operations, standard sprockets deliver the most cost-effective solution.

- Reinforced/Heavy-Duty Sprockets: Mining, quarrying, and heavy-duty environments impose extreme demands on sprockets. Reinforced sprockets typically feature fully hardened teeth with increased thickness, effectively resisting abrasion from silt and rock fragments. Data indicates reinforced sprockets achieve an average 30%–50% longer service life than standard variants. Though more costly, they represent a more economical choice for high-intensity construction enterprises.

- Monobloc vs. Split Sprockets: Monobloc sprockets are machined from solid steel blocks, offering high strength and resistance to loosening, making them suitable for prolonged heavy-duty operation. However, their drawback lies in cumbersome replacement procedures and extended downtime.Split sprockets comprise multiple tooth rings and a central hub. Replacement requires only the tooth ring section, saving time and costs, making them ideal for construction projects demanding rapid maintenance.

- Specification Matching: Chain sprocket diameter, tooth count, and pitch vary significantly across excavator tonnages. Generally, smaller excavators (1–10 tonnes) exhibit longer sprocket lifespans, whereas larger units (30 tonnes+) experience accelerated wear due to greater load-bearing pressures. Consequently, procurement must strictly adhere to model and tonnage specifications when selecting matching components.

Primary Causes of Sprocket Wear and Preventive Measures

Sprocket wear is inevitable, yet its rate and severity can be significantly mitigated through proper maintenance and operation. Common causes of wear are categorised as follows:

External Environmental Factors

In complex operating conditions involving mud, gravel, or wetlands, contaminants readily enter the meshing areas between sprockets and track links, accelerating tooth surface abrasion. Concurrently, rainwater and chemical substances may induce surface corrosion on the sprockets.

Internal Operational Factors

Excessively slack chain tension may cause chain skipping; conversely, excessive tension subjects the sprocket tooth surfaces to undue stress, accelerating wear. Furthermore, inadequate lubrication and uneven loading during operation are common latent damage factors.

Types of Wear

- Uniform Wear: Overall reduction in tooth height, diminishing meshing precision.

- Uneven Wear: Severe wear on one side of sprocket teeth, often caused by improper tensioning or faulty guide mechanisms.

- Tooth Sharpening: Gradual grinding of tooth tips into sharp angles, increasing chain slippage risk.

- Poor Meshing: Resulting from pitch errors or mismatched chain pitch.

Preventive Measures

- Maintain cleanliness of sprockets and tracks, regularly removing sediment deposits.

- Adjust chain tension according to manufacturer’s recommended standards.

- Lubricate regularly using grease suitable for operating temperatures and conditions.

- Establish a wear inspection log, recording data from each check to predict replacement cycles proactively.

Determining the Timing for Sprocket Replacement and Operational Procedures

Sprockets should not be replaced only after complete failure, but rather when wear reaches a certain threshold to prevent cascading damage to track links and the entire machine.

Wear Assessment Criteria

- Tooth height wear exceeding 50% of original height

- Excessive meshing clearance causing frequent chain tooth skipping

- Noticeable sharpening or uneven wear of tooth profiles

- Chain slippage or abnormal noises during operation

Mandatory Replacement Timing

Immediate replacement is essential when sprocket wear has caused abnormal chain damage or significantly reduced excavator efficiency. Failure to do so may result in track link failure, doubling repair costs.

Replacement Procedure

- Shut down the machine and implement safety precautions. Loosen the track tensioning device.

- Remove the old sprocket using hydraulic tools or a specialised removal tool.

- Clean the mounting area and inspect bearings and oil seals for wear.

- Install the new sprocket, ensuring perfect alignment with the track link.

- Tighten to the specified torque to prevent bolt loosening.

- Adjust chain tension and conduct a brief test run to observe meshing.

Common Issues and Solutions

- New sprocket meshing poorly: Verify model compatibility or check for severe chain wear.

- Abnormal noise after installation: Often caused by insufficient bolt tightening or misalignment.

- Premature wear: May result from inadequate lubrication or abnormal operating conditions.

Specialised Tools, Technical Methods and Safety Precautions

Replacing and inspecting sprockets demands both physical strength and technical expertise. Utilising specialised tools and standardised procedures ensures efficiency and safety.

Essential Tools

- Hydraulic wrench: For installing/removing high-torque bolts.

- Link splitter: Rapidly releases track links.

- Calipers and wear gauges: Precisely measure tooth height, pitch, and wear levels.

Technical Methods

- Alignment adjustment: Ensures the sprocket wheel and track are on the same centreline to prevent uneven wear.

- Torque standardisation: Tighten bolts to the manufacturer’s specified torque values.

- Wear data comparison: Regularly record and compare measurements to assess wear trends.

Safety Precautions

Excavators typically weigh several dozen tonnes. Strict safety measures must be implemented during sprocket wheel replacement:

- Secure the machine using jacks or dedicated support frames.

- Operators must wear hard hats, gloves, and protective footwear.

- For large equipment replacements, at least two personnel should collaborate to prevent accidents caused by human error.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

The excavator sprocket wheel is a core component of the track system, its condition directly impacting the machine’s operational efficiency and lifespan. Through correct maintenance practices, appropriate operating conditions, and scientific inspection and replacement procedures, the sprocket’s service life can be significantly extended, reducing overall operational costs.

Whether for routine construction or high-intensity mining operations, understanding sprocket types, causes of wear, and replacement techniques constitutes essential competency for both equipment managers and operators. Concurrently, selecting excavator sprocket manufacturers offering advanced manufacturing processes and reliable quality remains crucial for ensuring long-term, stable equipment performance.