Table of contents

- Basic Understanding of Excavator Bucket Pins and Bushings

- GFM’s Advantages in Bucket Pin and Bushing Manufacturing

- Common Problems and Symptoms of Bucket Pin and Bushing Quality

- Practical Methods for Testing Bucket Pin and Sleeve Quality

- Professional Inspection Steps and Operational Suggestions

- Daily Maintenance and Extending Service Life

Within the massive structure of an excavator, many people often focus first on the engine, hydraulic system, or track assembly, often overlooking inconspicuous components like the bucket pin and bushings. However, anyone who has truly engaged in excavator maintenance knows that the health of the bucket pin and bushings directly determines the excavator’s operating efficiency and service life.

The bucket pin is the core connection between the bucket and the boom and arm, while the bushings are protective components that ensure smooth operation and wear resistance. Poor quality of the bucket pin or bushings, or wear and excessive clearance after long-term operation, can not only lead to unstable excavator operation but also cause secondary damage between components and, in severe cases, even shut down the entire machine. Worse still, these problems are often not noticeable in the early stages, but once they occur, they can bring the construction site to a standstill and increase significant repair and replacement costs.

Basic Understanding of Excavator Bucket Pins and Bushings

To inspect the quality of bucket pins and bushings, you first need to understand their basic functions and design principles.

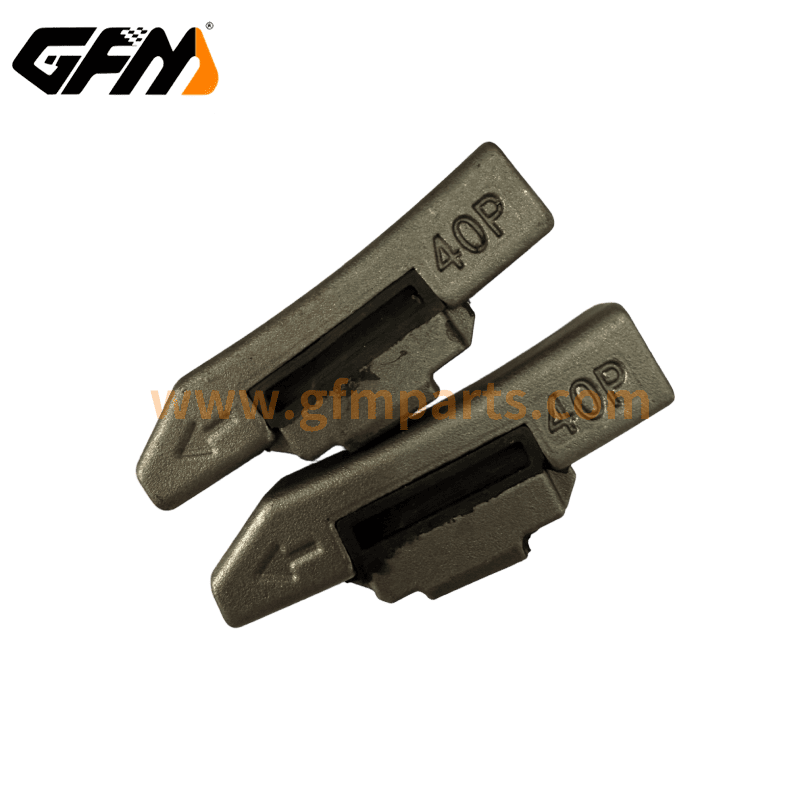

The bucket pin is the “joint” of the excavator’s working mechanism. Through high-strength connections, it withstands the tremendous impact forces generated by digging, lifting, and swinging. The bucket pin’s diameter, length, material strength, and surface treatment directly impact its load-bearing capacity and wear resistance. Generally, bucket pins are made of alloy steel and undergo heat treatments such as quenching or carburizing to ensure both hardness and toughness.

The pin sleeve acts as the “protective umbrella” for the bucket pin. It is typically embedded in the hole at the joint, reducing friction, cushioning impact, and extending the pin’s service life. Common sleeve materials include alloy steel, copper-based alloys, and polymer wear-resistant materials. High-end manufacturers often apply special treatments to the sleeve, such as spraying wear-resistant coatings and integrating oil grooves to enhance lubrication.

The bucket pin and sleeve are an inseparable pair. If the bucket pin is not sufficiently hard, it will easily bend or wear. If the sleeve material is not up to standard, the inner hole may quickly deform, resulting in excessive clearance. This clearance can cause vibration during excavator operation, reduce accuracy, and even damage other components. Therefore, their quality inspections must be considered together. Only when both pass muster can the stable operation of the entire machine be guaranteed.

GFM’s Advantages in Bucket Pin and Bushing Manufacturing

As a professional excavator parts manufacturer, GFM has extensive experience and rigorous standards in the production and testing of bucket pins and bushings.

First, GFM rigorously selects raw materials, often using high-strength alloy steel, and undergoes multiple heat treatment processes to ensure both hardness and toughness. Second, GFM utilizes advanced processing equipment, such as CNC grinders and high-precision boring machines, to ensure the dimensional accuracy of bucket pins and bushings.

During the inspection process, GFM not only uses conventional dimensional and hardness testing, but also incorporates specialized non-destructive testing technologies such as magnetic particle inspection and ultrasonic testing to ensure that every product meets high standards. More importantly, GFM has accumulated a wealth of customer case studies. Many construction companies have significantly reduced equipment failure rates and improved operational efficiency by using GFM’s bucket pins and bushings.

Common Problems and Symptoms of Bucket Pin and Bushing Quality

In actual use, bucket pin and bushing problems don’t suddenly appear overnight; instead, they often show signs of failure. Understanding these “early warning signs” can help us identify problems and take timely action.

Wear and Excessive Clearance

The most common problem is an increase in the clearance between the bucket pin and bushing. Normally, the bucket pin should fit tightly within the bushing, but over time, friction can cause the diameter to decrease or the bore to increase. When the clearance exceeds the normal range, the bucket will feel loose during operation, even accompanied by a metallic knocking sound.

Cracks and Fractures

Fine cracks are prone to developing when the bucket pin material is insufficiently hard or when it has been subjected to excessive loads for extended periods. If not detected promptly, these cracks will gradually expand and eventually lead to bucket pin fracture. Bushings may also experience edge chipping or flaking due to uneven load distribution.

Surface Spalling and Scratching

Some low-quality bucket pins have insufficient surface hardening thickness or uneven processing, which can cause spalling after a period of use. Lack of lubrication can also easily lead to visible scratches on the pin sleeve, which are signs of declining quality.

Insufficient Material Hardness

If the bucket pin is improperly heat-treated during manufacturing, resulting in low hardness, it will wear rapidly. Insufficient sleeve hardness can also lead to increased internal bore wear and deformation. These issues often require specialized testing tools.

Abnormal Sounds and Vibrations

When an excavator is operating, if there is an abnormal gap or damage between the bucket pin and sleeve, an unusual noise, such as a “clicking” sound, will be produced. This sound is often accompanied by vibration and is one of the most obvious warning signs.

Practical Methods for Testing Bucket Pin and Sleeve Quality

After understanding common problems, we need to use some practical testing methods to determine the quality of bucket pins and sleeves.

Appearance Inspection

The first step is the most intuitive appearance inspection. Visual inspection can detect cracks, flaking, scratches, or weld defects on the surface. In particular, if there are obvious grooves or slag on the bucket pin surface, the hardness layer is severely damaged.

Dimensional Measurement

Using a vernier caliper or micrometer, you can accurately measure the wear of the bucket pin diameter. The inner bore of the pin sleeve can also be measured with an inside micrometer. Generally, when wear exceeds the manufacturer’s tolerances, replacement is necessary.

Hardness Testing

Using a Rockwell hardness tester or Brinell hardness tester, you can check whether the bucket pin surface hardness meets the specified hardness. High-quality bucket pins typically have a hardness of around HRC 50. If the hardness falls below the standard, it indicates a problem with the heat treatment process.

Gap Testing

Using a feeler gauge or dial indicator, you can check the gap between the bucket pin and the pin sleeve. If the gap exceeds the specified value, operating accuracy will decrease or even cause seizure.

Non-destructive Testing

More specialized testing methods include magnetic particle testing and ultrasonic testing. These methods can detect fine cracks inside or on the surface of the bucket pin that would be missed by visual inspection. These methods are widely used by large repair shops and professional manufacturers.

Fit Accuracy Test

Install the bucket pin into the sleeve and operate it manually or mechanically to check for smooth movement and any sticking or wobble. This is an effective test method that combines theory with practice.

Professional Inspection Steps and Operational Suggestions

Inspecting the quality of bucket pins and sleeves is not a single action; it’s a comprehensive process. The following steps are provided as a reference:

Step 1: Disassembly and Cleaning

Before testing, disassemble the bucket pin and sleeve and thoroughly clean the surface with detergent to remove oil and impurities. This will prevent dust from interfering with the test results.

Step 2: Appearance and Surface Inspection

Observe the surface visually and with a magnifying glass, focusing on cracks, flaking, or poor welds.

Step 3: Dimension and Clearance Measurement

Use calipers, micrometers, dial indicators, and other tools to measure the bucket pin diameter, sleeve inner diameter, and fit clearance, and compare them to the standard values.

Step 4: Hardness and Strength Test

Use a hardness tester to check whether the bucket pin surface hardness meets the standard. If necessary, samples can be removed for metallographic analysis to assess the effectiveness of the heat treatment.

Step 5: Dynamic Operation Observation

Reinstall the inspected components and observe whether the excavator operates smoothly under low load and whether any unusual noises are heard.

Common Mistakes and Avoidance Methods

Many people tend to overlook lubrication during inspections or rely solely on visual inspection, which can lead to missed inspections. The correct approach is to combine multiple methods to ensure comprehensiveness.

Daily Maintenance and Extending Service Life

Inspection is only one part of ensuring quality; daily maintenance is equally important.

- Regular Lubrication: The interior of the bushing needs to be lubricated to reduce friction.

- Regular Clearance Checks: Measure the clearance to detect wear in a timely manner.

- Avoid Overloading: Prolonged, high-intensity operation accelerates wear.

- Record-keeping and Preventive Maintenance: Maintaining equipment records and regularly replacing wearing parts can prevent unexpected failures.

Through proper maintenance, the service life of bucket pins and bushings can often be more than doubled.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Although bucket pins and bushings are only small parts in an excavator, they play a vital role in the overall operation of the machine. Through scientific inspection methods and proper maintenance, we can not only avoid costly downtime but also significantly improve construction efficiency.

Choosing a high-quality manufacturer like GFM ensures the quality of bucket pins and bushings from the source. Users are responsible for routine inspection and maintenance. By developing scientific management habits, excavators can always maintain optimal condition, providing strong support for construction projects.