Table of contents

Structure of Excavator Buckets

Excavator buckets are essential components that directly interact with soil and rocks, affecting digging efficiency, stability, and lifespan. Understanding the main parts helps operators and maintenance teams work more effectively and choose reliable excavator bucket manufacturers.

- Bucket Body: The bucket body bears most operational forces and is usually made of high-strength wear-resistant steel. It includes the bottom plate, side walls, and back plate. Proper design and welding distribute stress evenly, preventing cracks and deformation while ensuring durability in different work environments.

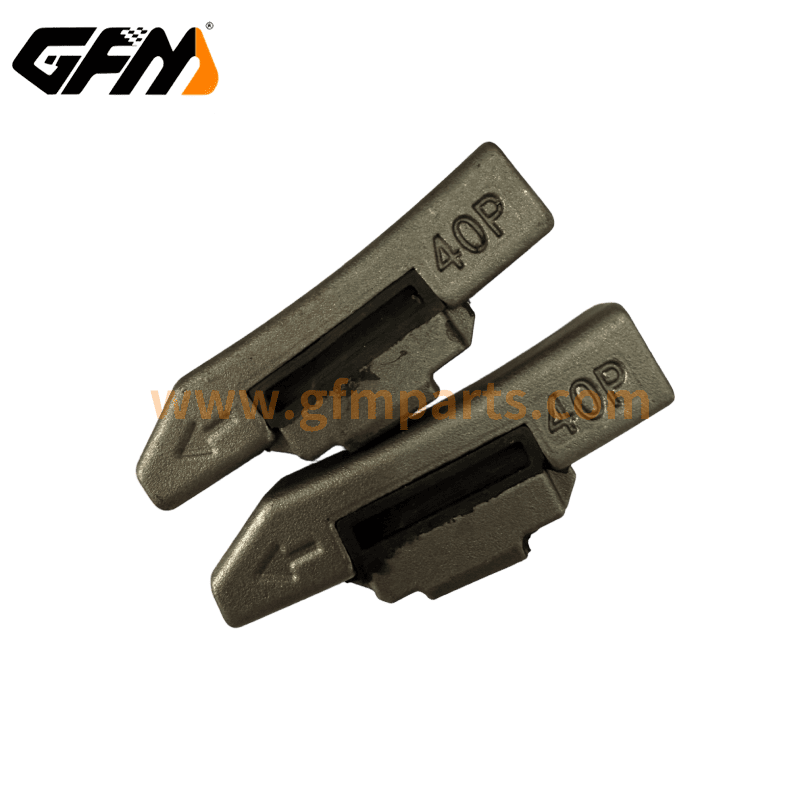

- Teeth and Tooth Adapters: The bucket teeth contact soil and rocks directly and are often the most worn parts. Teeth are mounted on adapters with bolts, allowing easy replacement and rotation. Sharp teeth suit soft soil, while wider or reinforced teeth are better for rocky or abrasive conditions, extending bucket life and maintaining efficiency.

- Pins and Bushings: Pins and bushings connect the bucket to the excavator arm, enabling motion and force transfer. High-quality heat-treated alloy pins resist wear and impact. Regular lubrication and clearance checks prevent looseness and ensure precise operation.

- Reinforcements and Wear Plates: Wear plates on the bottom, side walls, and corners reduce abrasion and extend bucket lifespan, especially in environments with constant friction. Their thickness and placement depend on actual work conditions.

Common Causes of Bucket Wear

Buckets inevitably experience wear over time. Understanding the causes helps implement effective maintenance to extend service life.

Types of Wear

- Tip wear: The bucket tooth tips, directly contacting soil and rock, wear the fastest and become blunt.

- Side wall wear: Side walls experience friction during rotation and digging, particularly noticeable during rotational loading.

- Bottom plate wear: The bottom plate constantly endures friction and impact, which may lead to thinning or surface scratches.

Impact of Working Environment

Soil type and working conditions significantly affect bucket wear. For instance, sandy and gravel environments accelerate bottom plate wear, while rocky environments increase tooth wear. Selecting the appropriate material based on actual working conditions is essential for durability and reliability.

Operator Habits

Improper operation accelerates wear, such as impact digging, high-frequency loading, or incorrect bucket angles. Skilled operators who adjust entry angles, control impact force, and manage load frequency can slow down wear and extend bucket lifespan.

Material and Manufacturing Influence

The material and manufacturing process determine the bucket’s wear resistance. High-strength wear-resistant steel and proper heat treatment significantly improve the durability of the bottom plate and teeth. Additionally, wear-resistant coatings or liners help reduce wear, especially in high-intensity operational environments.

Maintenance Tips to Extend Bucket Lifespan

Proper maintenance can minimize downtime, reduce operational costs, and improve efficiency.

Regular Inspection and Cleaning

- Clean the bucket after each shift, focusing on tooth and adapter gaps to prevent sand and debris accumulation.

- Inspect the bottom plate, side walls, and wear plates for cracks or noticeable wear.

- Check welds, bolts, and fasteners to ensure they are secure, preventing secondary damage.

Teeth Replacement and Rotation

- Replace or rotate teeth once wear is observed to ensure even wear.

- Choose tooth types based on environment: sharp teeth for soft soil, wide or reinforced teeth for rocks or gravel.

- Tooth rotation strategies can prolong overall bucket lifespan and reduce downtime.

Pin and Bushing Lubrication

- Regularly lubricate pins and bushings with high-quality grease to reduce friction and wear.

- Inspect pin clearances and replace worn bushings as needed.

- In extreme conditions, sealed bushings can prevent debris ingress, protecting the joint from wear.

Wear Monitoring and Early Warning

- Use measurement tools or wear markers to monitor bottom plate thickness and tooth length.

- Handheld thickness gauges or laser distance meters provide quick and accurate wear assessments.

- Maintain a wear log, correlate wear with working environment and frequency, and schedule maintenance or replacement proactively.

Professional Recommendations from Excavator Bucket Factories

Working with a reliable excavator bucket factory ensures better performance and extended lifespan.

High Wear-Resistant Materials and Heat Treatment

- Bottom plates and teeth should use high wear-resistant steel, heat-treated for improved hardness and toughness.

- High-wear areas may use additional wear plates or surface hardening treatments to extend life.

Matching Bucket Types to Work Requirements

- Different environments require different bucket types: standard digging buckets for soil, reinforced wear-resistant buckets for rocks or mining.

- Bucket capacity should match the excavator arm to avoid overloading, enhancing efficiency and reducing wear.

Wear-Resistant Liners and Coating Technology

- High-wear areas, such as the bottom plate and tooth adapters, can be equipped with liners or hardened coatings.

- These technologies reduce direct friction, increase durability, and lower replacement frequency and downtime costs.

Frequently Asked Questions (FAQ)

How often should buckets be replaced?

Buckets should be replaced when teeth or the bottom plate show wear affecting efficiency or safety. The exact interval depends on environment, operation, and materials.

When should teeth be rotated or replaced?

Teeth must be replaced when worn or cracked. Uneven wear can be mitigated by rotation to extend life.

Are there simple tools to monitor wear?

Yes, handheld thickness gauges can measure the bottom plate, laser distance meters or visual inspection can measure teeth, and wear markers can provide a quick assessment.

Is it worth working with a professional excavator bucket manufacturer?

A professional excavator bucket manufacturer provides high-quality materials, optimized design, and maintenance guidance, reducing downtime, lowering repair costs, and extending bucket life and efficiency.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Understanding the structure, wear causes, and maintenance tips of excavator buckets is crucial for safe, efficient, and durable operation. Through regular inspections, tooth management, lubrication, and wear monitoring, operators can significantly extend bucket life and reduce maintenance costs. Choosing a reliable excavator bucket factory that provides high-quality materials and optimized manufacturing processes ensures long-term operational stability.