جدول المحتويات

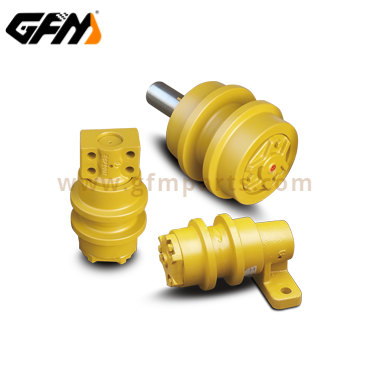

Understanding the Role of Excavator Carrier Rollers

Carrier rollers play a crucial role in supporting and guiding the track system of excavators and bulldozers, ensuring stable operation of the entire machine.

1. Structure of Carrier Rollers

Carrier rollers mainly consist of frames, roller bodies, bearings, and seals:

- Frame: Bears the weight and impact of the machine; the core of the carrier roller’s load-bearing function.

- Roller Body: Supports the upper track links via bearings, maintaining smooth track movement.

- Bearing: Ensures smooth rotation, reducing friction and wear.

- Seal: Prevents water, mud, and dust from entering the bearing area, extending service life.

2. Core Function

Carrier rollers support the upper track links, keeping the tracks stable on uneven terrain while distributing load, reducing vibration and wear, and improving operational efficiency.

3. Difference and Coordination with Idler Wheels

Carrier rollers are installed on the upper track and mainly guide and support the upper chain, while idler wheels are on the lower track, bearing the machine’s weight. Both work together to ensure track stability under heavy loads and extended operation.

4. Performance Indicators

High-quality carrier rollers must meet the following criteria:

- Load capacity: Withstand high impact loads.

- Wear resistance: Adapt to harsh conditions like mud and stones.

- Smooth rotation: Reduce machine vibration and noise.

- Impact resistance: Prevent cracks and deformation, extending service life.

Why Choose GFM as Your Carrier Roller Manufacturer

Since its establishment in 2011, GFM has focused on manufacturing undercarriage components for excavators and bulldozers, becoming a trusted مصنعي بكرات الناقل partner globally.

1. Factory Advantages

GFM’s factory is equipped with advanced CNC machining centers, automated heat treatment systems, and modern production lines, capable of handling large-scale orders with high precision and consistency.

- Production Scale: Supplies 1000+ types of parts, including bottom rollers, carrier rollers, idler wheels, sprockets, track shoes, and track chains.

- Modern Facilities: Combines forging and casting equipment with automated machinery to ensure strength and durability.

- Sufficient Inventory: Covers mainstream brands and models, readily meeting domestic and international customer needs.

2. Material and Process Advantages

Carrier rollers use high-strength alloy steel, undergo multiple forging and heat treatment processes, achieving surface hardness HRC50-55. This significantly enhances wear resistance and deformation resistance. Compared with ordinary rollers, GFM carrier rollers can last approximately 30% longer under harsh working conditions.

3. Quality Certification and Strict Management

GFM is ISO9001 certified. Each carrier roller undergoes dynamic balance testing, hardness inspection, dimensional precision verification, and sealing performance testing before leaving the factory, ensuring compliance with international standards.

4. Global Compatibility and Cooperation

Products are compatible with Komatsu, Hitachi, Caterpillar, Volvo, Kobelco, Doosan, Hyundai, Kubota, SANY, XCMG, LiuGong, Shantui and more, exported to Asia, Europe, and the Middle East.

GFM combines factory strength, advanced equipment, and extensive experience to provide reliable, durable, and high-performance بكرة حاملة للحفارة products.

The Manufacturing Process of GFM Excavator Carrier Rollers

GFM strictly controls the production process of carrier rollers, following international standards to ensure high precision and reliability.

- Material Forging: High-strength alloy steel is selected and forged multiple times at high temperatures with controlled cooling, ensuring dense metal structure and excellent toughness. Every forging is inspected to eliminate inclusions and porosity, ensuring durability and load-bearing capacity.

- Precision CNC Machining: Critical components such as roller bodies and bearing seats are processed with high-precision CNC machines, maintaining dimensional tolerance within ±0.02mm. This guarantees assembly accuracy and smooth rotation, reducing friction and extending service life.

- Heat Treatment Process: Carrier rollers undergo overall quenching and tempering along with high-frequency surface hardening. This balances surface hardness and core toughness, allowing the roller to withstand high loads while reducing wear, cracks, and deformation risks.

- Sealing Assembly: A double-layer dust-proof seal keeps grease inside while preventing mud and dust from entering the bearing area. High-precision assembly ensures smooth rotation under heavy-duty operation and reduces maintenance frequency.

- Inspection: Each carrier roller is tested for dynamic balance, hardness, dimensional tolerance, and sealing performance before leaving the factory. All data is traceable, ensuring consistent performance even under extreme conditions.

Advantages and Performance of GFM Excavator Carrier Rollers

- High Wear Resistance and Long Lifespan: GFM carrier rollers can last 20–30% longer than industry standards under high-load conditions, maintaining low wear and reducing overall maintenance costs.

- Excellent Sealing Performance: The double-layer composite seal prevents mud, stones, and moisture from entering the bearing area, ensuring long-term smooth rotation.

- Precision Assembly and Dynamic Balance: Dynamic balance testing ensures uniform rotation, low vibration, and reduced noise, improving overall machine comfort.

- Strong Compatibility: Products cover major brands such as CAT, Volvo, Doosan, Komatsu, and Hitachi, meeting diverse customer requirements.

- Proven Reliability: Extreme durability tests show GFM carrier rollers maintain stable operation under high temperature, humidity, and impact without structural damage.

GFM’s Technological Innovation and Global Service

- Technological Innovation: GFM develops lightweight and low-noise carrier roller designs to reduce machine energy consumption and improve operator comfort. Optimized roller cavity design increases strength by 12% and reduces weight by 10%.

- Smart Manufacturing Upgrade: The factory integrates automated inspection lines and robotic assembly systems, achieving full-process digital monitoring to ensure production accuracy and consistency.

- Global Adaptation and Supply: Carrier rollers are well-stocked, delivered promptly, and exported to Asia, Europe, and the Middle East, compatible with mainstream machine models.

- Eco-Friendly Manufacturing: Energy-efficient equipment, circulating lubrication systems, and low-carbon production processes ensure high-quality manufacturing while protecting the environment.

- Technical Support and After-Sales Service: GFM provides installation guidance, operational feedback, and long-term technical consultation, ensuring customers receive comprehensive lifecycle support.

| احصل على عرض أسعار سريع ومجاني | البريد الإلكتروني: henry@gfmparts.com | واتساب: +86 17705953659 |

With 14 years of industry experience, modern production facilities, and strict quality control, GFM has become a global leader among carrier roller manufacturers. Its excavator carrier roller products are trusted worldwide for their wear resistance, reliability, and compatibility, continuously advancing the construction machinery industry. Choosing GFM means selecting high-quality, long-lasting carrier rollers that maximize value for customers globally.