Table of contents

Understanding Excavator Track Components

In modern construction, mining, and infrastructure projects, excavators are among the most common heavy machinery. Their operational efficiency and stability directly determine project timelines and safety. The track components are the core system supporting the excavator’s movement and operations, bearing the highest load and experiencing the most wear in the entire machine.

Track components mainly include track shoes, sprockets, carrier rollers, idlers, and undercarriage chains. These parts collectively form the excavator’s walking system, with each component bearing significant mechanical stress:

- Track Shoes: Directly contact the ground, support the machine’s weight, and provide traction. Severe wear can cause slippage, reduced efficiency, and accelerated wear of other parts.

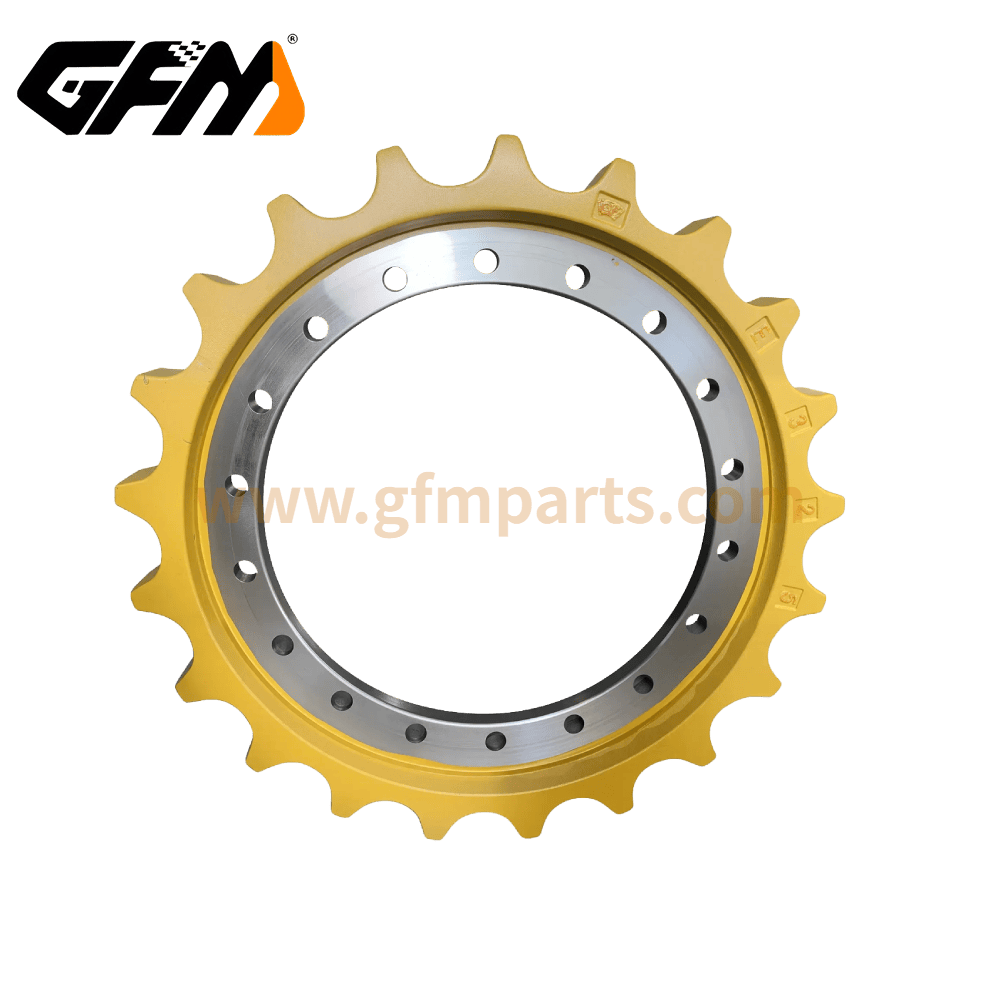

- Sprockets: Drive the tracks and are key in power transmission. Uneven wear can lead to track breakage or derailment.

- Carrier Rollers and Idlers: Carrier rollers support the machine’s weight, and idlers maintain proper track alignment. Deformation or wear can cause uneven track tension and machine deviation.

- Undercarriage Chains: Connect all components to form a complete track system and require high wear resistance. Loose or worn chains reduce efficiency and increase the risk of equipment failure.

According to the Construction Equipment Manufacturers Association (CEMA), high-quality track components can operate approximately 2,000–3,000 hours under standard conditions, while low-quality components last only 800–1,200 hours. This gap affects not only equipment stability but also directly impacts operational costs.

Key Factors for Choosing Excavator Track Components

Selecting suitable track components requires considering materials, working conditions, compatibility, and inspection methods.

- Material Selection: High wear-resistant steel and alloy steel are preferred, offering high hardness, good toughness, and impact resistance. Heat treatment or surface coating can further enhance wear resistance.

- Applicable Working Conditions: Different terrains demand different track designs: muddy environments require wider track shoes to prevent sinking, while rocky or gravel terrain needs high-strength links and impact-resistant sprockets.

- Compatibility: Track components must fully match the excavator model; otherwise, wear accelerates and failures may occur. Provide equipment model and working conditions to suppliers for the best recommendations.

- Inspection Methods: Before purchase, hardness testers can check steel hardness, or wear-testing machines can simulate real working conditions to ensure product performance.

- Supplier Selection: Purchasing from a reputable excavator parts manufacturer ensures reliable materials, precise machining, and access to technical support and after-sales service.

Considering these factors maximizes track system longevity and reduces maintenance costs and downtime.

How to Choose the Best Excavator Track Components

Selecting high-quality track components requires expertise and alignment with actual construction needs. Practical guidelines include:

- Clarify Construction Requirements

- Evaluate terrain: muddy, sandy, rocky, or mixed.

- Consider usage frequency: continuous or intermittent operation.

- Determine excavator model: track length, link count, and sprocket size must match.

- Track Shoe Type Selection

- Standard links: suitable for general conditions, cost-effective.

- Thickened links: suitable for high-intensity or rocky terrain, more wear-resistant.

- Wide track shoes: ideal for soft ground, enhancing traction and preventing sinking.

- Wear and Impact Resistance

- Choose high-strength alloy steel track components treated with heat or surface coating.

- Pay attention to sprocket tooth accuracy and chain tension to reduce wear.

- Cost vs. Longevity Balance

- High-quality components have higher initial costs but longer life and less maintenance, resulting in lower total costs.

- Select the most cost-effective solution based on budget and project schedule.

- Technical Support and Spare Parts

- Purchasing from reliable excavator tracks suppliers ensures access to standard parts, professional installation guidance, and after-sales support.

Following these steps helps construction teams maintain optimal performance across various terrains while minimizing downtime and maintenance.

Choosing High-Quality Excavator Track Components with GFM

GFM is a professional excavator parts manufacturer in China. Since its establishment in 2011, it has focused on the research, development, and production of excavator undercarriage components. Its products include tracks, sprockets, carrier rollers, idlers, track pins, bucket pins, and lock pins, widely applied in various medium and large construction equipment.

- High-Precision Machining: GFM has advanced CNC machining centers and heat treatment production lines. All components are manufactured according to strict tolerance standards, ensuring smooth assembly and stable operation. Precision machining reduces noise and wear, significantly improving equipment efficiency.

- Premium Wear-Resistant Materials: The company selects high-strength alloy steel and applies advanced heat treatment and surface hardening technologies. Components maintain excellent performance in gravel, rocky, and high-load conditions. Multi-layer anti-corrosion coatings also protect against moisture and saline-alkali corrosion.

- Strict Quality Control: GFM operates under the ISO9001 quality management system. Each batch is tested for hardness, wear resistance, and impact strength, with complete traceability mechanisms to ensure consistent product quality.

- Complete Specifications and Stable Supply: GFM products are compatible with major brands, including Komatsu, Caterpillar, Hitachi, Volvo, Kobelco, Doosan, Hyundai, Sany, XCMG, and LiuGong. The company maintains ready stock to quickly meet customer demands. Factory direct sales allow customers to obtain high-quality parts at reasonable prices.

- Comprehensive After-Sales and Technical Support: GFM provides installation guidance and technical consultation, helping customers properly install and maintain track systems. Its technical team offers usage and maintenance recommendations based on different working environments to extend component lifespan.

- Customer Performance Results: A construction company operating on mixed gravel and concrete terrain reported that after replacing track components with GFM products, equipment runtime increased by approximately 25% and maintenance costs decreased by 15%, significantly improving operational efficiency.

With stable quality and professional manufacturing capabilities, GFM has become a long-term trusted excavator tracks & undercarriage components supplier for domestic and international customers.

Common Problems and Solutions

Even high-quality components can experience issues without proper maintenance. Typical problems include:

- Loose Tracks: Caused by chain elongation or loose tension bolts. Regular inspection and adjustment are recommended.

- Chain Breakage: Due to link fatigue or uneven sprocket wear. Replace with high-wear components simultaneously.

- Derailment: Often caused by worn carrier rollers, misaligned idlers, or uneven tension. Check guiding systems.

- Uneven Wear: From complex terrain or improper operation. Avoid sharp turns and high-impact operations.

Industry statistics indicate that approximately 70% of track issues can be avoided with regular inspection and maintenance, reducing repair costs and extending overall equipment life.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

In the construction machinery industry, track system reliability determines operational efficiency and safety. Selecting high-quality components, matching suitable working conditions, and implementing proper maintenance are key to ensuring long-term, high-efficiency operation.

As an experienced excavator parts manufacturer, GFM provides precision-made, quality-controlled, and well-supported track solutions for global customers. Whether for construction or mining, choosing GFM ensures higher productivity and lower maintenance risks.

By combining scientific selection and ongoing maintenance, companies can reduce operational costs and maintain a competitive edge in the challenging construction market.