In the field of modern engineering machinery, excavators are important tools for foundation construction, and their operating stability is directly related to the progress and safety of the entire project. Among the various parts of the excavator, the undercarriage parts are undoubtedly the “skeleton” that supports the operation of the entire machine. Whether it is track chain, track idlers, track rollers, or idler wheels, sprocket wheels, and track shoes, these undercarriage parts all bear key functions such as load-bearing, walking, and positioning. Once these components have problems, the construction may be interrupted at the least, or the entire machine may fail or even cause a safety accident.

However, in reality, many purchasers often pay too much attention to the unit price when choosing undercarriage parts, while ignoring the professionalism of the manufacturer, the consistency of the product, and the long-term reliability. This short-sighted behavior of “only looking at the price” not only buries hidden dangers in the operation of the equipment, but may also lead to a continuous increase in maintenance costs. Therefore, choosing an excavator undercarriage parts manufacturer with professional background, rich experience, and customization capabilities can not only improve the overall performance of the equipment, but also bring stable benefits and competitive advantages to the construction unit.

GFM takes you to an in-depth analysis of what improvements can choosing a professional excavator undercarriage parts manufacturer bring to you? How to judge whether a manufacturer is truly reliable? And what key details should not be ignored during the cooperation process.

Table of contents

- Undercarriage parts quality advantages brought by professional manufacturers

- Cost saving is not a price war: the value of professional manufacturers from the maintenance and replacement frequency

- The secret of efficient construction: how the performance of undercarriage parts affects work efficiency and equipment life

- Customized service enables multiple working conditions: OEM/ODM support makes construction more powerful

- How to judge whether a manufacturer is trustworthy? Five key standards

Undercarriage parts quality advantages brought by professional manufacturers

A professional undercarriage parts manufacturer is first reflected in the full process control of product quality. From the selection of raw materials to precision processing, and then to the fine control of heat treatment process, professional manufacturers will accurately control every detail. For example:

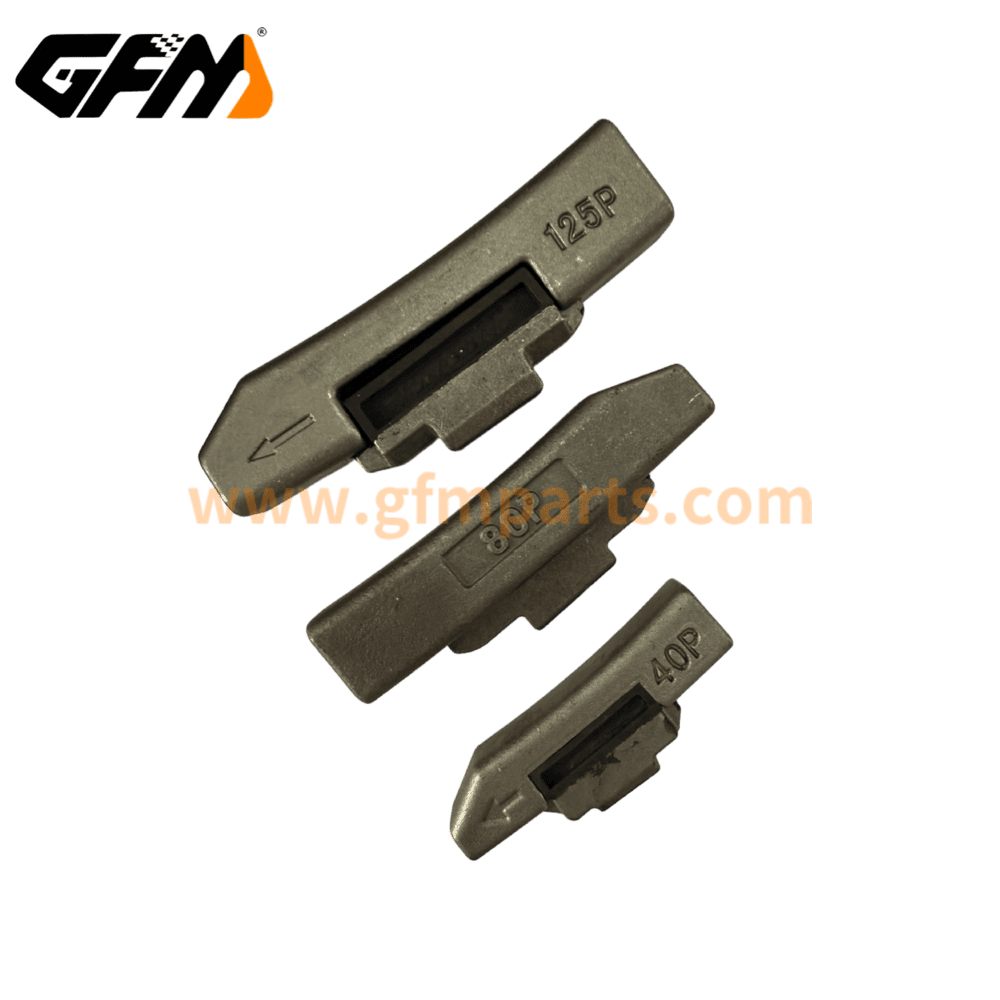

Raw material control: 40Mn, 35SiMn, SCMnH and other alloy steel materials specially used for high-strength working conditions are used. These materials have good toughness and wear resistance, and can adapt to complex working conditions such as mining, crushing, and wetlands.

Precision processing equipment: Use CNC machine tools, automated gear processing centers and other equipment for processing to ensure that the matching tolerance between parts is controlled within ±0.01mm, effectively reducing operating vibration and abnormal noise.

Heat treatment technology: Professional manufacturers usually have a full set of quenching and tempering, carburizing, and induction quenching equipment. By controlling the heating time, temperature, and cooling rate, the surface hardness of the parts can reach HRC50 or above, while ensuring that the core remains tough and not easy to break.

Surface treatment: Including phosphating, electrophoretic spraying, thermal spraying and other anti-rust and corrosion processes, effectively extending the service life of parts in humid or corrosive environments.

In addition, professional manufacturers will also establish a strict testing system, including metallographic analysis, tensile testing, fatigue testing, full dimensional inspection, etc., to ensure that each batch of products meets the specified performance indicators.

Cost saving is not a price war: the value of professional manufacturers from the maintenance and replacement frequency

Many users prefer low-priced parts in the initial purchase, but this strategy is often not worth the loss in later use. Because the undercarriage parts that do not meet the quality standards have a fast wear rate and a high failure frequency, the final result is:

- High replacement frequency, requiring multiple shutdowns for maintenance.

- Due to accidental damage, the chain jumps the track or the equipment deviates, and it needs to be overhauled or even returned to the factory.

- Construction delays bring risks of breach of contract and reputation damage.

Take the chain track as an example: the chain track in the general market needs to be replaced after about 800 hours of use, while the high-strength chain track produced by professional manufacturers can last up to 1200-1500 hours, and can even maintain good condition under special working conditions.

From the perspective of maintenance, high-quality undercarriage parts have higher surface finish and better lubrication, which can effectively reduce the accumulation of foreign matter and sludge pollution, and reduce maintenance difficulty and labor costs.

The secret of efficient construction: how the performance of undercarriage parts affects work efficiency and equipment life

The construction efficiency of the excavator depends not only on the power of the engine and the skills of the operator, but also on the stability and accuracy of the undercarriage system. The structural design, matching accuracy, tension control, etc. of the undercarriage parts will affect the walking track, climbing ability and anti-skid performance of the whole machine.

For example:

- Inconsistent chain track pitch will cause walking jitter, affecting construction accuracy.

- Uneven force on the track rollers can easily cause eccentric wear, resulting in track jamming or even chain breakage.

- Unreasonable arrangement of the sprocket wheel will cause excessive fluctuations in the tension of the chain track and reduce the running stability.

- The deviation of the guide wheel may cause the track to frequently drop the chain and interrupt the construction.

Professional manufacturers will use CAE finite element analysis software to optimize the structure of stress concentration points in the design of undercarriage parts. When assembling parts, special positioning tooling and hydraulic pressing process are used to ensure that the tension of each assembly point is uniform and the error is controllable. And through the whole machine simulation test, the passability, maneuverability and working stability of the whole vehicle are improved.

This is directly related to whether the equipment can operate continuously on complex terrains such as soft soil, stone, and slopes, reducing the failure rate and unplanned downtime, and indirectly improving the engineering efficiency of the whole project.

Customized service enables multiple working conditions: OEM/ODM support makes construction more powerful

Although standardized products are suitable for most construction needs, in many special scenarios, they still need to be personalized according to the environment and construction intensity. At this time, manufacturers with OEM/ODM capabilities are particularly important.

For example:

Wetland track shoes: When constructing in paddy fields, swamps and other places, widened and non-slip track shoes are required, and the material must have a certain degree of flexibility to avoid sinking.

Special track chain for crushing: The chain rail tooth shape is strengthened, and the material is made of high-toughness alloy to improve impact resistance.

Support wheels in extremely cold areas: Low-temperature special grease is required, and the sealing ring material must also adapt to the minus 40°C environment.

Professional manufacturers can provide customers with one-stop services from design-proofing-testing-batch delivery through sample co-creation, collaborative development of drawings, and rapid trial production to ensure that the product is highly matched with construction equipment and working conditions.

How to judge whether a manufacturer is trustworthy? Five key standards

Manufacturing equipment and production capacity: Does it have modern equipment such as large CNC machine tools, heat treatment lines, automatic welding equipment, and robot arms? Is the daily output stable?

Technical team and process capabilities: Is there an independent team of design engineers and quality control engineers? Can it provide technical support such as 3D modeling and structural analysis?

Product testing and quality control system: Has it passed ISO9001, CE, SGS and other certifications? Does it have raw material spectrometers, hardness testers, fatigue testing machines and other testing equipment?

Customer cases and industry experience: Have you served OEMs or overseas engineering customers? Do you have more than 10 years of industry experience? Can you provide project feedback and real-life application pictures?

Delivery capabilities and service response: Can you quickly make samples? Are there professional after-sales engineers to assist in installation and technical consultation? Is the delivery on time?

When selecting manufacturers, it is recommended that the purchaser conduct an on-site inspection of the factory, observe the workshop layout and employee proficiency, check the shipping records and customer return visit materials, and avoid blindly believing in propaganda.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Choosing a professional excavator undercarriage manufacturer not only means better product quality, longer service life and less after-sales troubles, but also means that you have laid a solid foundation for the successful construction of the project. With the continuous escalation of construction difficulty and the increasing refinement of equipment management, having a stable and efficient undercarriage system has become an important part of engineering competitiveness.

A truly professional manufacturer understands products and construction. They can help you reduce the total cost of equipment ownership (TCO) and improve project completion efficiency and construction safety with the support of technology, experience and services.

So, next time you are shopping for undercarriage parts for your project, please look further and spend more time to understand the real professional manufacturers – you will find that this is an investment that will pay off far more than expected.