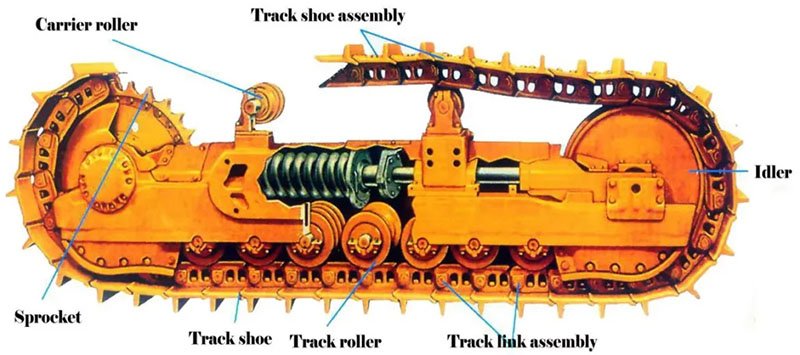

As an important part of excavators and bulldozers, track rollers directly affect the stability and working efficiency of the machines. Correct selection and maintenance of excavator track roller can not only extend the life of the equipment, but also reduce operating costs.

Basic concepts and functions of track rollers

Definition and function

Introduction to rollers: Track rollers usually refer to key wheel components installed on excavators or bulldozers to support the weight of the entire machine and buffer the impact force during operation.

Main functions:

- Stability improvement: When the machine is running, the weight of the machine body is evenly shared to ensure overall stability;

- Impact absorption: Reduce mechanical impact in rugged road conditions or high-intensity operations;

- Wear dispersion: Reduce local wear and increase service life through reasonable design.

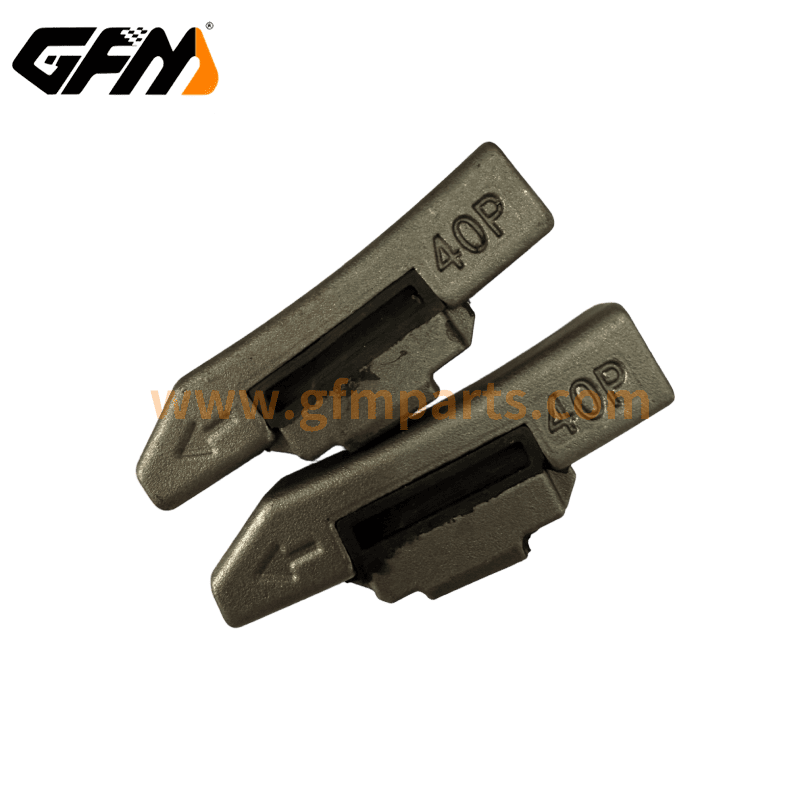

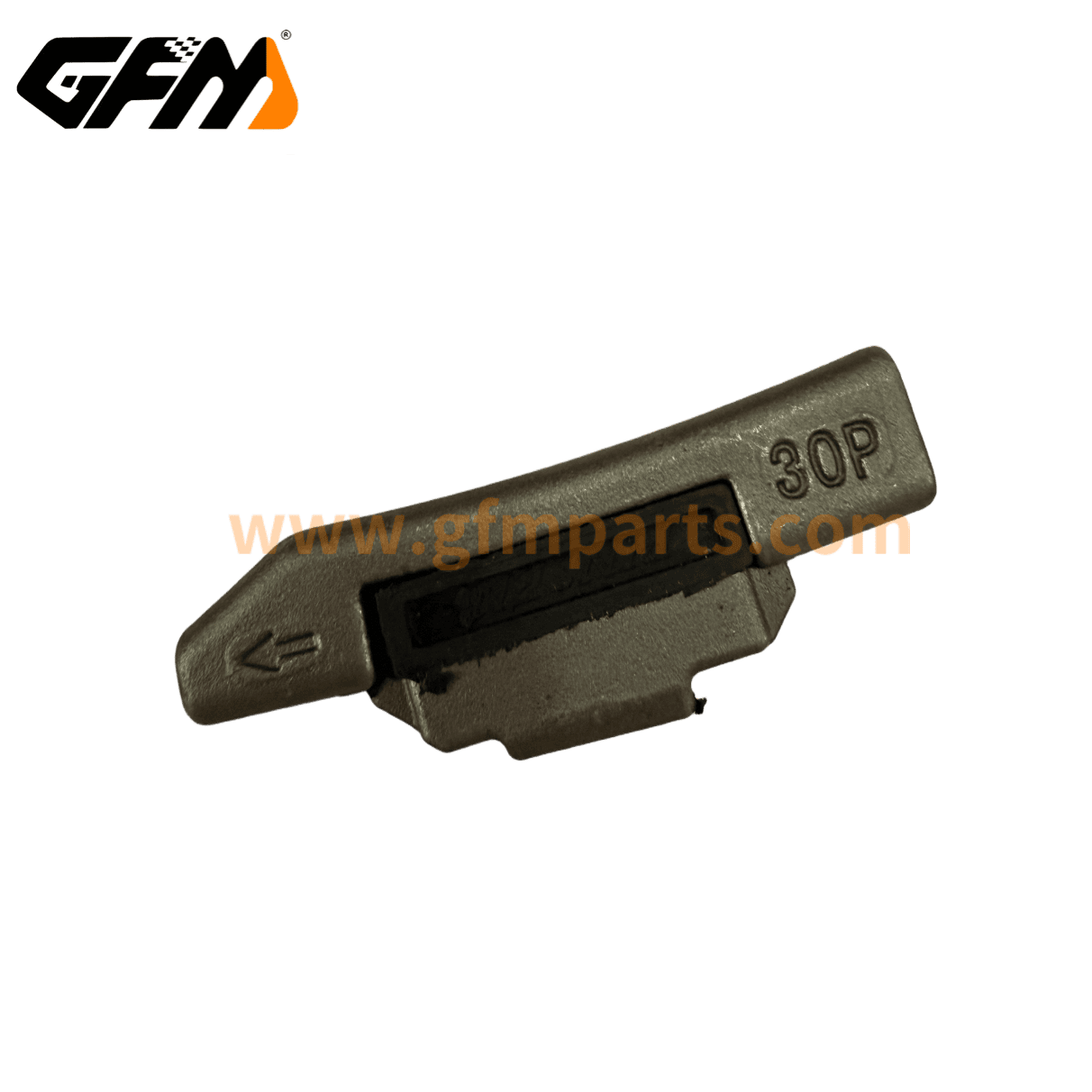

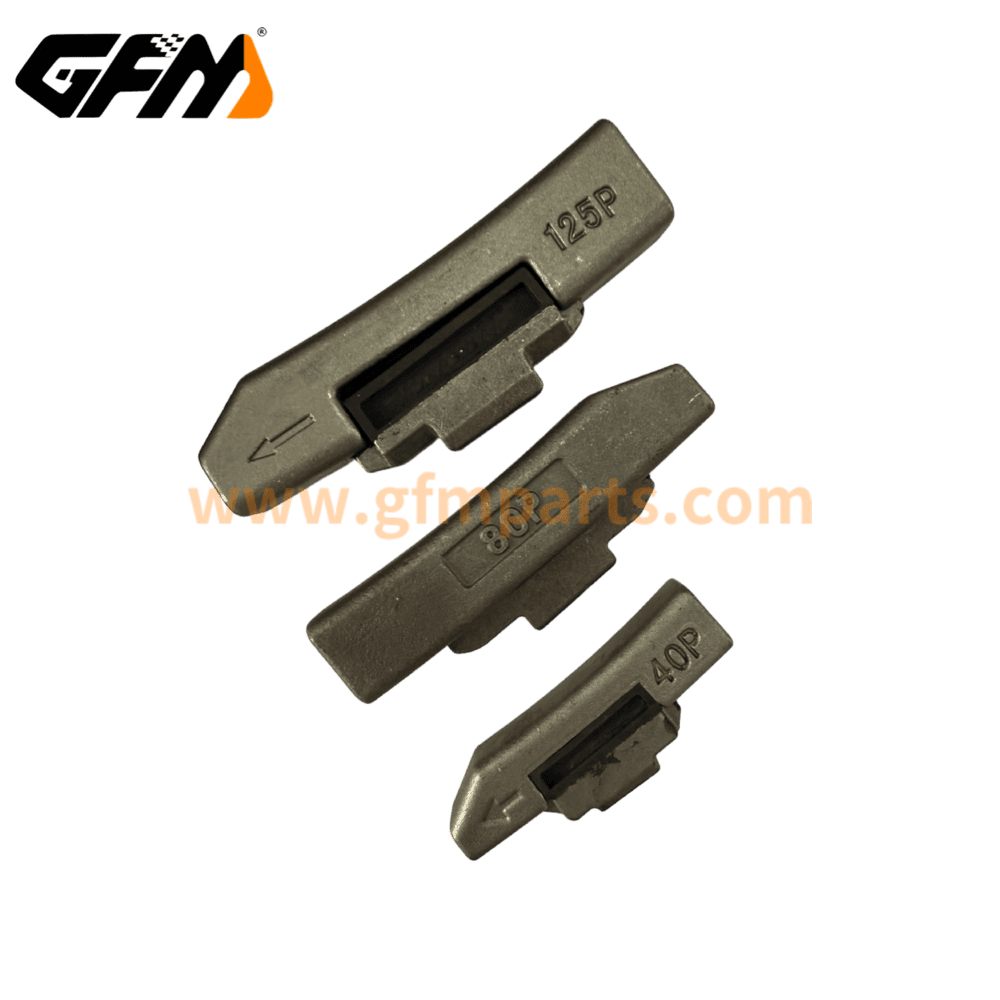

Conceptual distinction between SF and DF bottom rollers

- Single rollers: Usually installed on one side of the equipment, with a relatively simple design structure, suitable for light loads or special working conditions.

- Double rollers: Symmetrical arrangement on the left and right, which can disperse the weight more evenly and is suitable for high-load and high-intensity working scenarios.

Design principles of SF and DF track rollers

Comparison of structural design and mechanical properties

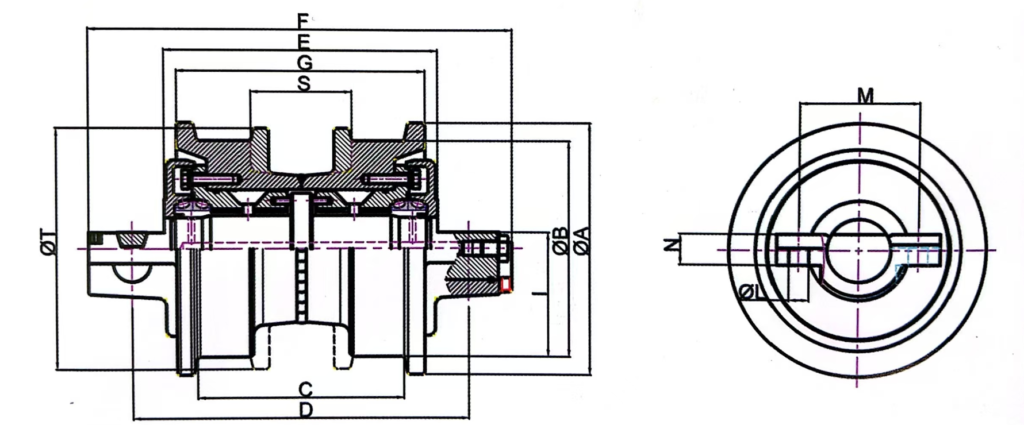

SF track roller

- Structural features: The wheel rim is set on one side, and the wheel body is asymmetrically designed, usually used with open track rails.

- Mechanical principle: The lateral displacement of the track is constrained by the single-sided wheel rim, and the vertical load is transmitted by the contact surface between the wheel body and the track link. Its structure is simplified and the weight is light, but the ability to resist lateral impact is limited.

- Typical applications: small and medium-sized agricultural excavators, light bulldozers, and low-load working conditions.

DF track roller

- Structural features: High-strength wheel rims are set symmetrically on both sides to form a closed guide structure, which is suitable for track systems with higher sealing.

- Mechanical principle: The synergistic effect of the double-sided wheel rims realizes the three-dimensional constraint of the track, greatly improving the ability to resist torsional loads and lateral impacts. The double-sealed bearing system is mostly used inside the wheel body to enhance dust and water resistance.

- Typical applications: large mining excavators, heavy-loaded bulldozers, rugged terrain or high-impact working conditions.

Material and manufacturing process

- Material selection: High-strength alloy steel and wear-resistant rubber are usually used to improve impact resistance and wear resistance.

- Manufacturing process: Precision casting and forging processes ensure structural strength, and subsequent heat treatment and surface treatment are used to further improve fatigue resistance.

Comparative analysis of SF and DF track rollers

Performance comparison

| Comparison dimensions | SF Track Roller | DF Track Rollers |

| Carrying capacity | Optimized for loads in specific directions, with strong local performance ≤15 tons (light equipment) | Balanced overall load distribution, suitable for high-load conditions 80 tons (medium and heavy equipment) |

| Side impact resistance | Medium | Excellent |

| Structural complexity | Simple structure, relatively easy design and installation | More complex design, requiring higher manufacturing accuracy |

| Crawler guide accuracy | ±5mm | ±2mm |

| Cost | Low manufacturing cost and low maintenance cost | Higher cost, but more stable long-term operation |

| Maintenance cycle | 200-400 hours | 500-800 hours |

| Manufacturing cost | Low (reduced by 30% material usage) | High (requires precision machining) |

Usage scenarios and selection considerations

SF track roller:

- Suitable for occasions where the wheel system is not required and the working environment is relatively stable;

- Suitable for small or medium-sized equipment, with advantages when pursuing lightweight design

DF track rollers:

- Suitable for high-intensity operations, complex terrain, and long-term continuous operation;

- Suitable for large-scale mechanical equipment, with high requirements for overall stability and durability.

How to choose the right roller – 5 core considerations

Comprehensively considered key factors

Equipment type and tonnage

- ≤15-ton equipment prefers single-sided design (cost-sensitive)

- ≥20-ton equipment is forced to use double-sided structure (safety redundancy)

Operation environment analysis

- Flat hard ground: single-sided roller

- Muddy/slope/gravel site: double-sided roller

Economic evaluation

- Short-term project: single-sided (low initial cost)

- Long-term operation: double-sided (40% lower full-cycle maintenance cost)

Accessory compatibility

- Confirm that the track shoe model matches the roller flange spacing

Regulations and safety standards

- Mining operations must comply with ISO 10262 explosion-proof certification

Selection steps

- Data collection: Collect equipment operation data and historical maintenance records.

- Load analysis: Conduct mechanical calculations and simulation tests to evaluate the applicability of single-sided and double-sided solutions.

- On-site verification: Test and verify the selected solution to ensure that the theoretical design is consistent with the actual working conditions.

- Cost-effectiveness evaluation: Comprehensively consider the initial investment and long-term operation and maintenance costs, and select the most cost-effective solution.

Common problems and maintenance methods of SF and DF track rollers

Typical failure modes

Single track rollers:

- Asymmetric wear of wheel rim (accounting for 62%)

- Seal failure leads to bearing jamming (mud intrusion)

- Wheel body cracks (overload impact)

Double track rollers:

- Synchronous wear of double flanges (insufficient lubrication)

- Floating oil seal leakage (high temperature causes rubber aging)

- Shaft sleeve micro-motion wear (exceeding the matching tolerance)

Common problems

- Wear and fatigue:Due to long-term operation, the wheel surface and internal components may be worn, cracked, or even fatigued.

- Uneven load phenomenon:Single-sided rollers are prone to excessive local force under uneven load conditions, resulting in deformation or early failure.

- Improper installation:Improper installation or adjustment may cause the track roller to be loosely connected to the machine body, causing vibration or noise problems.

Maintenance methods and operation procedures

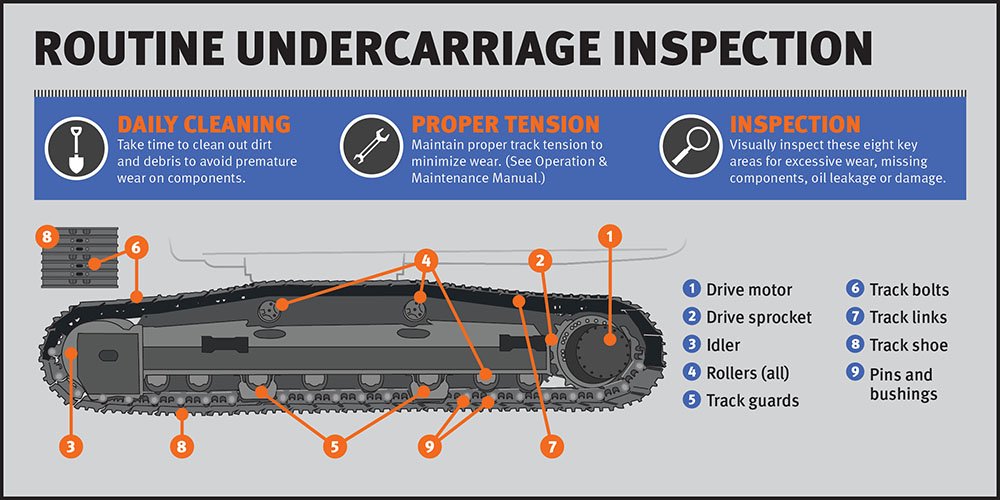

Regular inspection and diagnosis:

- Use professional testing instruments to regularly inspect the wheel surface for wear, cracks and deformation;

- Use vibration monitoring to promptly detect eccentric load problems.

Disassembly and cleaning:

- According to the requirements of the operating manual, ensure that the equipment is in a safe state before disassembling the track roller;

- Thoroughly clean the wheel body and internal components to remove wear particles and impurities.

Replacement and repair:

- For severely worn or cracked parts, it is recommended to directly replace the track roller;

- Minor wear can be repaired by surface grinding or reinforcement measures to ensure that the design requirements are met before reassembly.

Adjustment and reset:

- Perform precise adjustment after installation to ensure that the wheel body is perfectly connected to the main structure;

- Record the adjustment data for future maintenance reference.

Regular lubrication and anti-rust treatment:

- Periodically lubricate the mechanical connection parts to prevent metal fatigue and corrosion.

Maintenance and care of SF and DF bottom rollers

Daily maintenance measures

- Cleaning and maintenance: Regularly clean the rollers and the surrounding environment to prevent the accumulation of mud and impurities;

- Lubrication management: According to the requirements of the equipment manual, use the specified lubricant for regular maintenance to ensure the smooth operation of all moving parts;

- Environmental monitoring: Pay attention to factors such as the temperature and humidity of the operating environment, and adjust the maintenance strategy in time.

Regular inspection and professional maintenance

- Inspection cycle: It is recommended to conduct a comprehensive inspection after a certain number of hours of operation and record the wear data;

- Professional maintenance: Professional technicians perform regular maintenance to ensure that the equipment is in the best working condition;

- Data analysis: Use modern monitoring technology to analyze the equipment operation data, predict potential failures and intervene in advance.

Life cycle maintenance strategy

Daily inspection

Lubrication management:

- Check grease leakage every 8 hours

- Use NLGI #2 grade extreme pressure lithium grease

Wear monitoring:

- Laser rangefinder detects wheel rim thickness (accuracy 0.1mm)

- Infrared thermal imaging monitors bearing temperature rise (alarm threshold 85℃)

Preventive maintenance

Cleaning procedures:

- High-pressure steam cleaning (pressure ≤150Bar)

- Acid and alkali solvents are prohibited

Tightening strategy:

- Tighten bolts according to the torque gradient method (M24 bolts: 450±10% N·m)

Overhaul cycle

- Single-sided roller: mandatory renovation after 2000 working hours

- Double-sided roller: overall replacement after 5000 working hours

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

When selecting suitable bulldozer track roller, the operating environment, load requirements, equipment type, and long-term operation and maintenance costs should be fully considered. Only with the dual guarantee of scientific selection and strict maintenance can the stability and safety of the equipment be ensured and the best economic benefits be achieved.