What are tooth adapters for excavators?

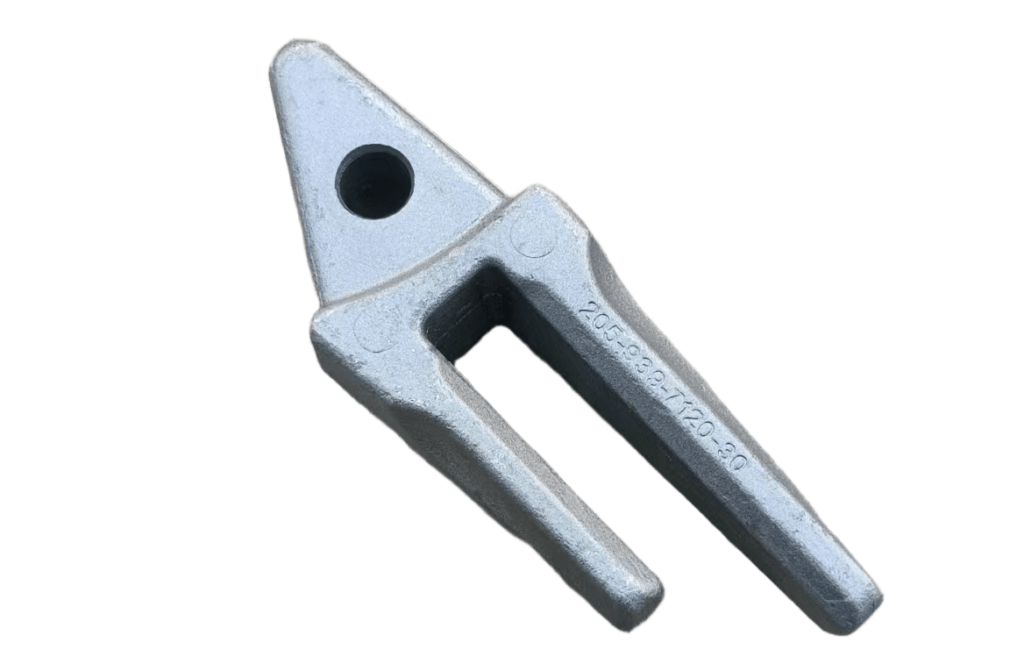

A tooth adapter for excavators is an intermediate device that connects the bucket and teeth of an excavator. It is usually made of high-strength steel and is designed to withstand the tremendous pressure of excavation operations. The main function of a tooth adapter is to firmly connect the bucket to the teeth while providing a certain degree of flexibility so that the teeth can maintain good performance during operation.

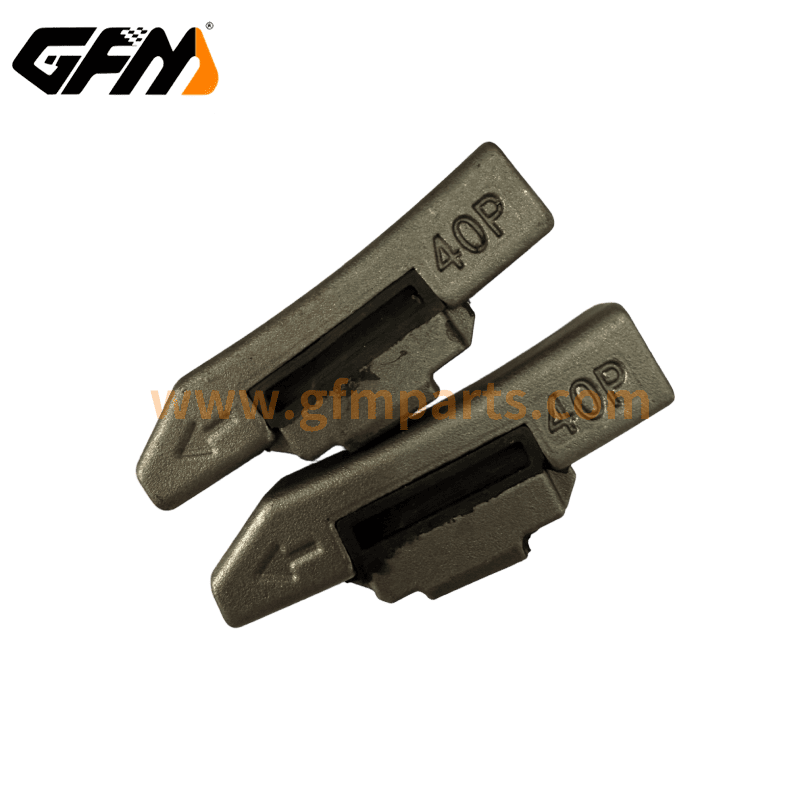

The design of tooth adapters is generally divided into several types, such as:

- Bolt-on type: The adapter is tightly connected to the teeth by bolts, which is suitable for high-intensity excavation operations.

- Slot-type adapter: The teeth are clamped by the slot structure for quick disassembly and assembly.

- Weld-on adapter: Welded directly to the bucket for higher durability.

How tooth adapters for excavators work

The bucket tooth adapter fixes the teeth to the excavator bucket through a close-fitting slot or bolt connection. When the excavator is digging, loading or bulldozing, the tooth adapter transmits the digging force to the teeth, ensuring that the teeth cut into the soil or rock efficiently. Due to the design of the adapter, it can reduce direct wear on the bucket teeth and bucket, and increase the service life of both.

In addition, the adapter also plays a role in absorbing impact forces, which reduces vibration during high-intensity operations of the excavator, thereby protecting the overall structure of the equipment.

Why do you need a bucket tooth adapter?

Bucket tooth adapters play the following key roles in the daily operation of the excavator:

- Enhanced stability: Provides a stable connection to ensure that the bucket teeth will not fall off during high-intensity operations.

- Dispersed pressure: The impact force during excavation is dispersed through the adapter, reducing the wear of the bucket and bucket teeth.

- Easy to replace: When the bucket teeth are worn or damaged, the adapter design makes replacement easier, thereby reducing downtime.

- Improved work efficiency: The adapter ensures that the bucket teeth are always in the best working position, thereby improving work efficiency and results.

Common bucket tooth adapter failures

Although the bucket tooth adapter is made of durable materials, the following failures may still occur during high-intensity operations:

1. Wear: After long-term use, the surface of the adapter may show obvious wear, affecting the strength of the connection.

- Performance: Loose connection, bucket teeth cannot be fixed.

- Cause: Long-term friction between the adapter and the bucket teeth.

2. Deformation: When overloaded or subjected to strong impact, the adapter may deform, resulting in a failure to fit closely with the bucket teeth.

- Performance: Bucket teeth are displaced and the operation effect is reduced.

- Cause: Material fatigue or improper operation.

3. Cracks: Due to material fatigue or external force, the adapter may crack, and further use may cause breakage.

- Performance: Cracks appear on the appearance, accompanied by abnormal noise.

- Cause: Long-term high-intensity operation or adapter quality problems.

Damage to connecting parts: For example, bolt breakage or slot wear causes the adapter to be unable to be fixed normally.

Daily maintenance and care

In order to extend the service life of the excavator bucket tooth adapter, the following maintenance measures are recommended:

Regular inspection: Before and after each operation, check the connection of the adapter to ensure that there is no looseness or obvious wear.

- Check the connection points of the adapter every week, especially the tightness of the bolts.

- Check whether the adapter has cracks or deformation.

Timely cleaning: Remove dirt and gravel from the surface of the adapter to avoid accumulation of foreign matter and increased wear.

- It is recommended to clean up once a day after work, especially after working in muddy environments.

Lubrication and maintenance: Apply an appropriate amount of lubricant to the connection parts to reduce wear and prevent rust.

- Use high-quality anti-rust lubricant to ensure long-lasting lubrication.

Replace worn parts: When the adapter is found to be severely worn or cracked, it should be replaced in time to avoid affecting work efficiency.

- Choose high-quality adapters that match the original parts to avoid installation problems due to size mismatch.

Avoid overload operation: Use according to the rated working conditions of the excavator to avoid deformation or damage of the adapter due to overload.

- Regularly train operators to ensure reasonable use of equipment.

Record maintenance logs: Establish equipment maintenance records, and regularly check and analyze the use of adapters.

Advantages of GFM excavator bucket tooth adapters

As a leading excavator bucket teeth supplier, GFM provides high-quality bucket tooth adapters with the following significant advantages:

- High-strength material: Made of high-quality steel, it has excellent wear resistance and can work stably in extreme environments.

- Precision manufacturing: Strict process control ensures that each adapter is accurate in size, seamlessly installed, and reduces later adjustment time.

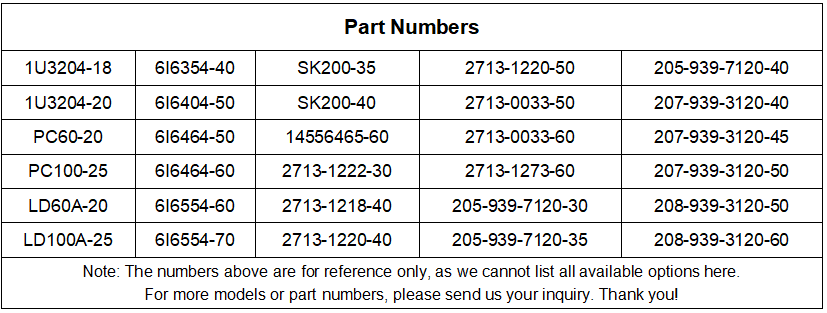

- Diverse selection: Adapt to different types of excavators to meet the needs of various working conditions, including mining operations, construction and water conservancy projects.

- Excellent service: Provide professional technical support and fast after-sales service to help customers solve problems efficiently.

- Customization capability: Support customized adapters according to customer needs to meet the use requirements of specific working conditions.

Whether you are engaged in mining or earthmoving, choosing a high-quality bucket tooth adapter is a key step in optimizing the performance of your excavator. For more details, please visit our official website or contact our professional team.

Optimize your excavator performance, start with choosing a high-quality bucket tooth adapter!

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |