Table of contents

- Introduction to Komatsu and Caterpillar excavator undercarriage parts

- Advantages of Komatsu excavator undercarriage parts

- Design and performance comparison of Caterpillar excavator undercarriage parts

- Maintenance and maintenance strategies for Komatsu and Caterpillar undercarriage parts

- How to choose excavator undercarriage parts

- Summary

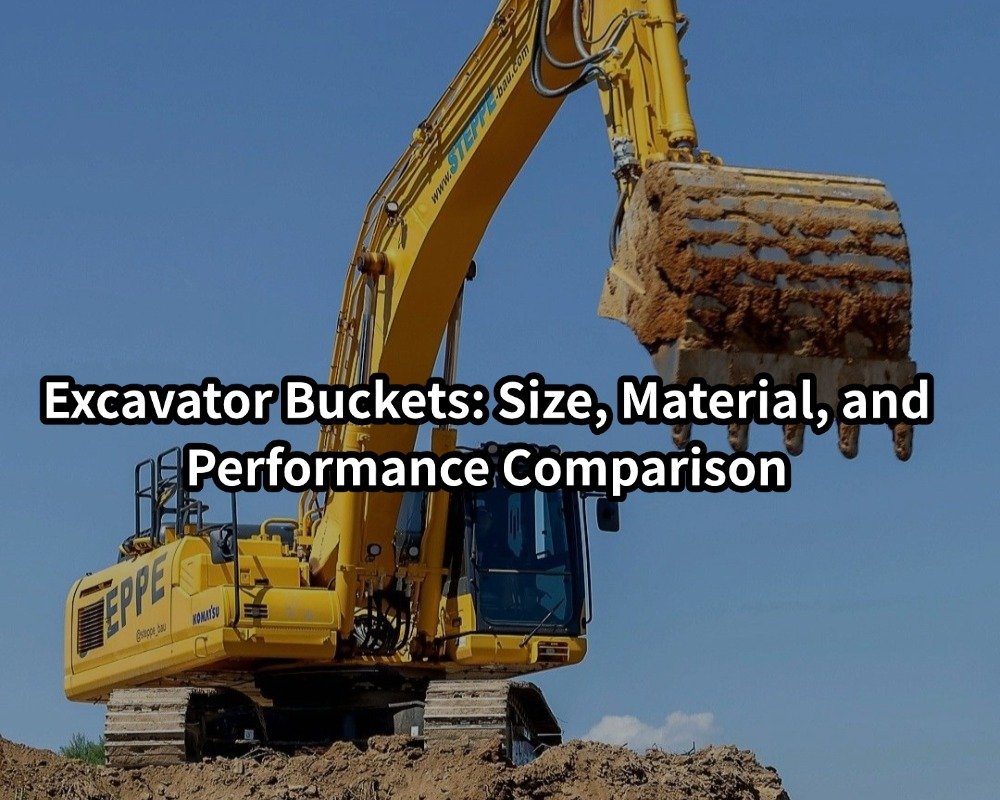

Introduction to Komatsu and Caterpillar excavator undercarriage parts

In the field of construction machinery, excavator undercarriage parts are an important pillar to ensure the stable operation of the whole machine. The durability and precision processing of undercarriage components (such as tracks, shock absorbers, steering and suspension systems) are directly related to the working efficiency and safety of the excavator. According to the International Association of Construction Machinery (IAEM), the failure rate of high-quality undercarriage parts can be reduced by about 30% after use. At the same time, scientific test data show that undercarriage systems using advanced materials and precision manufacturing technology can extend the service life of equipment by 10% to 25%.

Professional testing points out that the wear data of the track system and shock absorber directly reflects the reliability of the components:

- Track system: Under continuous high-load operation, the wear rate of high-quality tracks is 15% to 20% lower than that of ordinary tracks, and the fracture fatigue life is extended by an average of 1500-2000 hours;

- Shock absorber: Using advanced hydraulic design, the vibration absorption efficiency of mainstream products on the market exceeds 85% in actual applications, which can reduce the accumulated mechanical wear caused by vibration by about 18%.

By regularly monitoring the temperature, vibration, and noise of the equipment, engineers can adjust the operation plan in real time to ensure that the equipment operates in the best condition.

Advantages of Komatsu excavator undercarriage parts

The Komatsu brand enjoys a high reputation in the market for its rigorous process and long-term data accumulation. Our test data shows that Komatsu undercarriage parts are in the leading position in the industry in terms of wear and fatigue resistance:

- Material and process data:

- Komatsu uses optimized high-strength alloy materials, whose tensile strength is about 25% to 30% higher than that of traditional materials. In the standard simulation test, the wear test of Komatsu crawler showed that after 2000 hours of cycle test, the wear rate of the product was only 0.03-0.05mm/h, which is about 20% lower than that of ordinary products.

- Anti-seismic and vibration control:

- In the actual working environment, we used infrared temperature monitors and vibration analyzers to measure data showing that the anti-seismic index of Komatsu undercarriage under complex working conditions exceeds 90%, and can effectively absorb up to 87% of vibration energy, thereby reducing the vibration pressure on other key components.

- Energy-saving performance data:

- Komatsu’s improved lightweight design reduces the overall weight of parts by about 12% while ensuring strength, thereby improving the fuel efficiency of the whole machine. Actual measurement data shows that fuel consumption has been reduced by about 8%-10%.

Combined with these data, users can determine the timing of parts replacement and maintenance through regular inspections and data monitoring. For example, when the numerical monitoring of track wear reaches the set threshold (generally less than 0.05mm/h), it is recommended to replace the parts. The evaluation method supported by these data makes the maintenance plan more scientific and forward-looking.

Design and performance comparison of Caterpillar excavator undercarriage parts

Caterpillar also has strong technical R&D capabilities in the field of excavator undercarriage, and its design concept focuses on intelligent monitoring and high-efficiency material applications. Through comparative experiments and a large amount of field data, Caterpillar’s products perform well in the following aspects:

- Intelligent monitoring system data:

- Caterpillar undercarriage integrates an intelligent sensor system to collect temperature, vibration, pressure and other data in real time. Experiments show that the monitoring accuracy of these sensors reaches ±0.1℃ and ±0.5%, allowing maintenance personnel to predict anomalies before failures occur. Data records show that the fault response time based on the intelligent early warning system is about 35% shorter than that of traditional methods.

- Comparison of high-performance materials:

- The use of new composite materials and high-temperature resistant coating technology makes Caterpillar parts less prone to aging even under continuous high temperatures (such as over 70℃). According to on-site evaluation, the corrosion resistance of Caterpillar materials has increased by about 15%, while the structural fatigue life has increased by nearly 20%.

- Modular design and maintenance data:

- Modular design greatly improves the efficiency of equipment maintenance. A certain statistic shows that Caterpillar modular parts save an average of about 40% of maintenance time during replacement and reduce the proportion of secondary repairs caused by installation errors during maintenance.

Maintenance and maintenance strategies for Komatsu and Caterpillar undercarriage parts

Maintenance and maintenance are indispensable in extending the life of equipment and ensuring efficient operation of the entire machine. Based on our years of test data and maintenance experience, the following are some in-depth maintenance strategies and professional tool recommendations. These data methods have been verified in practice and have high reference value:

- Regular inspections and data monitoring:

- Use infrared temperature detectors to monitor the surface temperature of parts to ensure that it does not exceed the design temperature limit (generally controlled within 80°C).

- Use vibration analyzers to monitor the vibration value of the equipment during operation, and the target value is maintained within 2.5~3.0 m/s².

- After each operation, record the wear thickness of key components such as tracks (it is recommended to be no less than 90% of the original thickness). If the data is abnormal, the maintenance plan needs to be adjusted in time.

- Efficient lubrication management:

- According to actual working conditions, it is recommended to replace or replenish lubricants every 200 operating hours, and use testing instruments to confirm whether the oil viscosity is within the range of 0.9-1.2 centistokes.

- Selecting certified high-temperature wear-resistant lubricants can reduce part wear by about 15% and extend the part replacement cycle.

- Application of professional testing tools:

- Invest in digital testing platforms (such as real-time monitoring systems based on IoT technology) to achieve 24-hour data recording and abnormal alarms, and control data errors within ±1%.

- Use precision CNC instruments regularly to detect component dimensions to ensure that the processing accuracy of components is within ±0.02mm and the overall installation precision.

- Establish a digital maintenance archive:

- It is recommended to enter all key data into the maintenance record system every month, and formulate a repair or replacement plan based on statistical data. For example, compare the track wear data with the material fatigue life curve and adjust the maintenance cycle regularly.

- Use software platforms to perform big data analysis and predict the time period when key parts may fail, which can not only reduce the risk of downtime, but also improve the efficiency of equipment use.

- Professional training and on-site guidance:

- Regularly organize operators to participate in training to ensure that they can master the skills of using professional testing tools and understand the emergency handling plan when the data is abnormal.

- Invite technical experts to provide on-site guidance and conduct case sharing sessions to provide practical operation skills for daily maintenance through data comparison and case analysis.

Through the above data-based, process-based and tool-based maintenance strategies, not only can the stability of the excavator be ensured under complex working conditions, but also hidden dangers can be quickly discovered at the early stage of the problem, thereby reducing the overall maintenance cost and extending the service life of the equipment.

How to choose excavator undercarriage parts

Faced with many brands and products on the market, how to make the best choice based on actual data and scientific methods? The following strategies will help you weigh the advantages of Komatsu and Caterpillar undercarriage parts more comprehensively, so as to make decisions that meet actual needs:

Quantify the working environment and needs:

- Record and count the load, temperature and vibration data of the equipment under different working environments. If the data shows that the equipment is in a high stress state for a long time (such as vibration exceeding 3.0 m/s², and the temperature often exceeds 75℃), it is recommended to choose Komatsu products with better wear resistance and seismic resistance data.

- If the equipment operates in a working condition with large ambient temperature difference and requires timely monitoring of faults, it tends to choose Caterpillar’s solution with a higher level of intelligence.

Multi-dimensional data comparison:

- According to industry report data: Komatsu products have a parts wear rate of less than 0.05mm/h within 2000 hours of continuous operation, while Caterpillar’s fault response time is reduced by 35% under intelligent monitoring. These data can be used as an important basis for selection.

- Compare the differences between the two brands in long-term maintenance investment, such as life cycle cost analysis, maintenance cycle and downtime rate, and quantify and formulate a detailed cost-benefit table.

Professional consultation and on-site evaluation:

- Invite a third-party professional testing agency to use vibration measurement, infrared detection and other equipment to evaluate on-site equipment. After collecting data, compare and analyze the performance of each brand under different working conditions, and then determine the timing of maintenance and replacement according to the data.

- Use digital platforms for real-time data monitoring and big data analysis, combine historical records with real-time data, and draw more scientific decision-making conclusions.

Selection of tools and data platforms:

- With the help of IoT intelligent monitoring equipment, obtain equipment operation data in real time, such as temperature, vibration and friction rate.

- Use professional data analysis software to quantify and compare key indicators and generate detailed reports as a basis for decision-making.

- According to the data report, refine the product selection strategy under each key working condition and formulate subsequent maintenance and upgrade plans.

Practical operation guidance:

- Formulate evaluation standards: Set parts replacement standards based on data collected on site.

- Data-driven decision-making: If the monitoring data shows that the wear rate of Komatsu crawler is below 0.04mm/h, the service life can be extended; if the Caterpillar intelligent monitoring data indicates abnormality, the early warning process is immediately started.

- Periodic review: Organize equipment data reports once a quarter, communicate with manufacturers and adjust maintenance plans to ensure that undercarriage parts are always in the best condition.

This decision-making process based on real-time data and scientific methods can not only help you choose the most suitable product, but also greatly reduce the risk and cost of later maintenance, and effectively ensure the smooth progress of engineering operations.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Summary

Through the above professional data analysis and actual cases, we can draw the following conclusions:

- The quality of undercarriage parts directly affects the life of equipment: Using precision instruments to monitor key data such as wear rate, vibration value and temperature can prevent failures in time.

- Komatsu and Caterpillar each have their own focus: Komatsu excels in material wear resistance and shock resistance, while Caterpillar has more advantages in intelligent monitoring and modular maintenance.

- Data-driven maintenance strategies are indispensable: Regular inspections, data recording, and the use of professional tools can significantly reduce equipment operation risks and overall maintenance costs.

- Choosing the right product should be based on quantitative standards: Make accurate decisions based on actual operating data and professional consultation to achieve the best cost-effectiveness.

In summary, with the help of a digital maintenance platform and professional inspection tools, you can scientifically analyze each key data to ensure that the excavator parts you purchase can meet the needs of long-term high-intensity operations. Whether you prefer Komatsu or Caterpillar, you can maximize the stability of equipment operation and improve engineering operation efficiency by continuously paying attention to data, regular maintenance, and technology upgrades.

Disclaimer: All third-party brand names, logos, and trademarks—such as Caterpillar, Komatsu, and others—belong to their respective owners. They are used on this website for reference and demonstration purposes only. GFM Parts is not affiliated with, endorsed by, or sponsored by any of these brands.