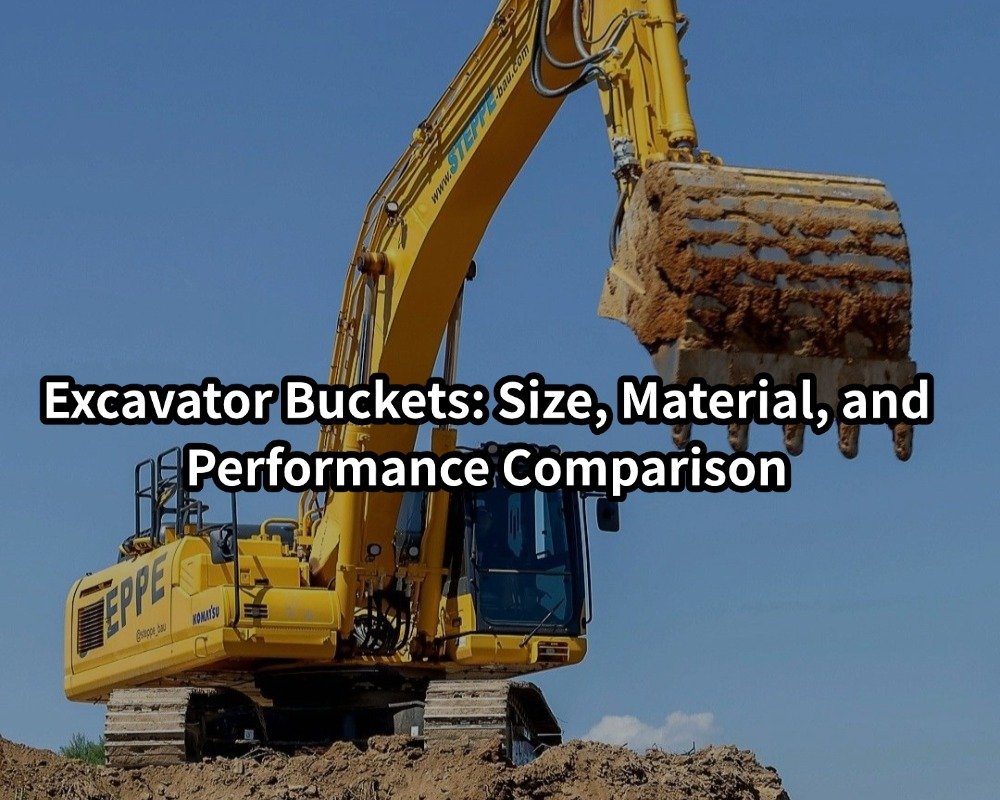

Among all kinds of heavy engineering machinery, bulldozers are widely used in construction, mining, water conservancy and other engineering projects because of their powerful capabilities in tasks such as site leveling, earthwork stripping and obstacle removal. One of the keys to whether a bulldozer can operate efficiently and stably is its undercarriage system. A stable and durable bulldozer undercarriage can directly affect the traction, stability and service life of the whole machine.

Although people usually focus on the engine power, blade structure or tonnage of the bulldozer, in fact, one of the key parts that determines whether a bulldozer can work efficiently for a long time is often the undercarriage system. As the core component that bears the weight of the whole machine and is in direct contact with the ground, the rationality of the structure, matching and maintenance status of the undercarriage directly affect the stability, traction and service life of the whole machine.

Undercarriage parts are not only the “legs and feet” of the bulldozer, but also the bridge connecting the upper structure and the ground. In high-intensity, long-term, and high-frequency construction tasks, a stable, wear-resistant, and scientifically designed undercarriage system can greatly improve the performance of the entire machine and reduce the risk of downtime caused by component failure.

Table of contents

- Full explanation of the structure of bulldozer undercarriage parts

- Precautions and operation strategies under different working conditions

- Bulldozer undercarriage maintenance and maintenance recommendations

- How to choose bulldozer undercarriage parts suitable for different working conditions

- GFM: Providing undercarriage solutions for global projects

Full explanation of the structure of bulldozer undercarriage parts

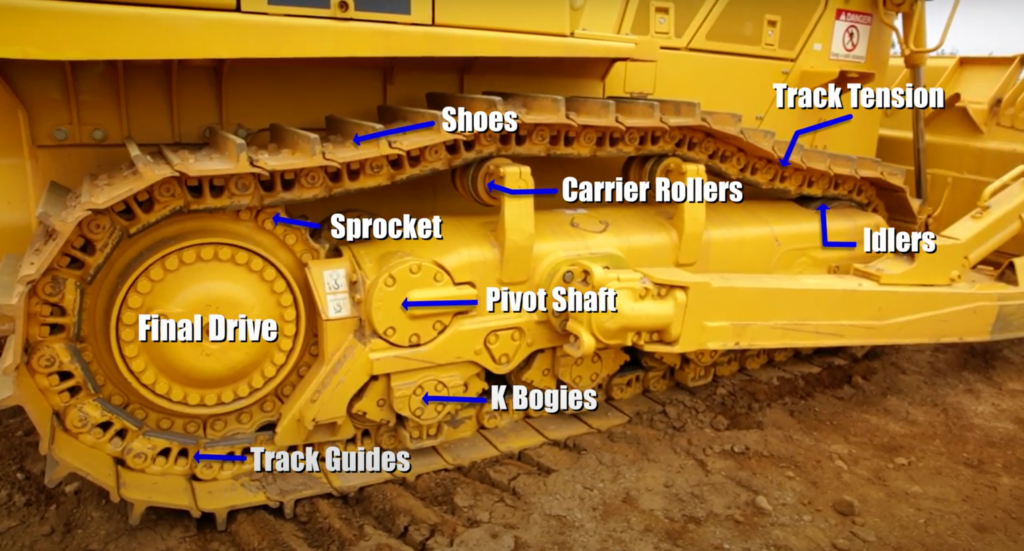

Bulldozer undercarriage parts are a complex motion support system, mainly including the following key components:

Track Chain

The track is the direct medium for the bulldozer to contact the ground, consisting of several chain links and pins. Its function is not only to support the weight of the entire machine, but also to form the driving force for the bulldozer to move forward and backward through engagement with the sprocket. The pitch size, material strength, wear resistance and other factors of the track determine the adaptability of the bulldozer in different environments. For special terrains, such as snow, soft soil or rugged rocks, tracks with different tooth shapes and structures can be selected to achieve optimal performance.

Track Shoe

The track shoe is installed on the chain link and is the part of the bulldozer undercarriage that is in direct contact with the ground. Its width, thickness and surface design determine the passability and stability of the bulldozer. For example, wide track shoes can effectively disperse the weight of the equipment and prevent it from sinking into muddy ground, while thickened track shoes are more impact-resistant and suitable for heavy-load scenarios such as quarries. Some track shoes are also designed with transverse teeth on the surface to enhance grip and avoid slipping.

Bottom Roller and Carrier Roller

The bottom roller is located under the track to carry and distribute the weight of the entire machine; the carrier roller is located above the track to support the return track. Both seem simple, but they face high-frequency impact and wear during long-term operation, so their bearing structure, sealing ring design and material selection must be excellent. If the bottom roller is severely worn, the track will be unevenly grounded, causing the bulldozer to shake or even deviate.

Idler

The guide wheel is installed at the front end of the track. Its function is to guide the direction of the track and adjust its tension. Modern bulldozers mostly use an automatic tensioning guide wheel system, which can adjust the track tension in real time according to the working conditions to ensure stable and smooth operation of the equipment.

Sprocket

The sprocket realizes power transmission by meshing with the track chain link. Its tooth structure and material strength determine the meshing efficiency and durability. If the sprocket tooth profile is excessively worn, it will not only affect the walking efficiency, but also easily cause the chain link to bite and break, which will cause the whole machine to fail.

Track Adjuster

The tensioner adjusts the track tension through a cylinder or spring system. If the tension is too small, the track is easy to fall off. If it is too large, it will increase the friction between components and cause overheating. In daily maintenance, it is necessary to regularly check whether the tensioner is in normal condition and adjust it in time.

These undercarriage components must work together precisely to ensure the stable operation of the bulldozer under complex working conditions.

Are you looking for quality bulldozer parts at the best price? You have come to the right place. We are committed to providing excellent products and offering the best value to our customers. Your satisfaction is our motivation. Send an email to henry@gfmparts.com now and our bulldozer undercarriage experts will be happy to serve you.

Precautions and operation strategies under different working conditions

Muddy wetland working conditions

In swamps, river channel regulation, and farmland operations, bulldozers face problems such as soft foundations, severe soil adhesion, and frequent vehicle sinking. In such environments, the following measures should be taken:

- Use ultra-wide track shoes to increase buoyancy and reduce ground pressure.

- Install a track structure with a self-cleaning design to reduce mud retention.

- After each shift, use a high-pressure water gun or manual cleaning tool to remove mud.

- The tensioning device needs to be checked regularly to avoid tension failure due to mud blockage.

Rock and gravel working conditions

The ground in areas such as mines and quarries is hard and covered with gravel, and the undercarriage components are exposed to high-frequency impact and friction for a long time. Recommendations:

- Use track shoes and sprockets made of high-chromium alloy steel to enhance wear resistance;

- Use thickened chain link pins to extend service life.

- Monitor the expansion of cracks in metal parts and replace wearing parts in advance.

- Limit equipment from turning sharply, starting and stopping frequently, and reduce impact loads.

High temperature and dry working conditions

In deserts and plateaus, high temperatures and dust pose a double test to undercarriage components. Attention should be paid to:

- Use high temperature resistant grease to prevent dry friction of bearings after grease volatilization.

- The tensioning system needs to use heat-resistant materials and prevent the track from deviating due to thermal expansion and contraction.

- Check the aging of the seal ring to prevent dust from entering key parts and causing abrasion.

Extremely cold snowy working conditions

In areas covered with ice and snow, the ground is slippery and the temperature is low, the brittleness of metals is enhanced, and lubricants are easy to freeze:

- Use low-temperature special lubricants, antifreeze and other working condition-adapted materials.

- The track shoes use anti-skid tooth structures to improve grip.

- After the operation, remove the frost on the tracks to prevent freezing at night.

- Deploy electric heating systems or diesel preheating systems to improve starting efficiency.

Slope or uneven terrain working conditions

The road conditions in mountainous and hilly working areas are complex and require high stability. Attention should be paid to:

- Use sprocket wheels and track rollers with automatic balancing systems.

- Track tension control needs to be consistent on both sides to prevent the body from swaying.

- The position of the sprocket and the guide wheel needs to be coaxially corrected to avoid track slanting.

Bulldozer undercarriage maintenance and maintenance recommendations

In order to maintain the best performance of the undercarriage components, it is recommended to implement the following maintenance strategies:

- After each shift, check the tightness of the track and remove the adhesion with a shovel or high-pressure water gun.

- Check the wear of the track chain links and pins once a week. If they are loose or cracked, they should be replaced in time.

- Lubricate and inspect the bearing status of the bottom wheels, sprocket wheels, and sprockets every month.

- Perform undercarriage alignment calibration every quarter to ensure that all components run coaxially.

- Use original or high-quality certified accessories to avoid chain damage caused by low-quality parts.

For detailed maintenance manuals, please see: How to Maintain the Bulldozer Undercarriage Parts

How to choose bulldozer undercarriage parts suitable for different working conditions

Facing different geological conditions and operating requirements, it is particularly important to choose the right undercarriage configuration. The following points are for your reference:

- Terrain factors: wide tracks are preferred for soft ground, and floating track roller systems are used for terrain with large elevation differences.

- Climatic conditions: heat-resistant seals and high-temperature grease are required in high-temperature areas; antifreeze oil circuits and preheating devices should be provided in cold areas.

- Work intensity: thick track shoes and forged sprockets should be selected for long-term heavy-load conditions.

- Budget control: Selecting high-quality accessories or GFM customized parts while ensuring quality can reduce procurement and operation and maintenance costs.

GFM: Providing undercarriage solutions for global projects

As a manufacturer with many years of experience in the production of excavator and bulldozer parts, GFM is committed to providing global customers with high-strength, adaptable and durable undercarriage solutions. Our undercarriage components are widely used in extreme environments such as Middle East oil fields, African mining areas, Eurasian railways, and South American rainforests, and have received good feedback.

As a leading bulldozer parts manufacturer, GFM has automated track production lines, precision heat treatment processes and high-strength alloy steel manufacturing capabilities, covering a full range of undercarriage components such as bulldozer tracks, sprockets, bottom rollers, sprocket wheels, idler wheels, track shoes, etc.

We provide:

- Customized undercarriage solutions for different working conditions.

- High wear resistance, high strength, and high adaptability design.

- Fast delivery and global after-sales technical support services.

Whether it is mud, gravel, extreme cold or high temperature working conditions, GFM can provide bulldozer undercarriage component solutions that match your needs.

In addition, we also provide online working condition analysis services, global technical support and local after-sales systems to ensure that you can work stably and efficiently at any construction site.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Although the bulldozer undercarriage is often overlooked, it carries the durable operation and efficient operation of the entire machine. By scientifically selecting suitable undercarriage components and maintaining them regularly, not only can the life of the entire machine be significantly extended, but also the operating costs can be effectively reduced.

If you are looking for a professional bulldozer parts manufacturer or customized undercarriage solutions, please feel free to contact GFM. We will provide solid support for your project with reliable quality and professional services.

If you have any undercarriage-related questions or customized needs, please feel free to contact GFM. We will escort your construction project with professional services.