Excavators play a vital role in various engineering operations. However, the wear and replacement of excavator teeth have always been a key factor affecting work efficiency and cost-effectiveness. To solve this problem, GFM excavator parts manufacturer has launched high-quality tooth pins to help users improve the overall performance and operating efficiency of excavators.

What is an excavator bucket teeth pin?

The excavator tooth pin is an important component that connects the tooth seat and the tooth tip of the bucket tooth, usually made of high-strength alloy steel. The tooth pin firmly connects the tooth seat and the tooth tip through the pin shaft to ensure that the bucket tooth can work stably during the excavation process.

The function and principle of the teeth pin

The main function of the tooth pin is to ensure the stability and durability of the bucket tooth during the excavation process. During the excavation process, the bucket teeth will be subjected to huge squeezing force from the excavated materials. The bucket tooth pin effectively transmits and disperses these forces through precise matching and solid structure, thereby protecting the bucket teeth from damage.

Production process

GFM excavator bucket tooth pin production process strictly follows high-standard quality control. Starting from material selection, high-strength and high-wear-resistant alloy steel is used as the main material. After a series of complex process steps such as electric furnace refining, vacuum degassing, continuous casting billet, high-temperature offline rolling, air cooling, etc., the internal structure and surface quality of the steel are ensured to reach the optimal state. Subsequently, precision machining and heat treatment are carried out to ensure that the dimensional accuracy and physical properties of the bucket tooth pin meet the design requirements.

How to judge the quality of the bucket tooth pin?

The quality of the bucket tooth pin is mainly judged based on the following aspects:

- Material quality: High-quality bucket tooth pins are made of high-strength and high-wear-resistant alloy steel with good mechanical properties and wear resistance.

- Manufacturing process: Precision manufacturing process ensures the dimensional accuracy and surface quality of the bucket tooth pin, reducing friction and wear during use.

- Matching accuracy: The matching accuracy of the bucket tooth pin with the bucket tooth seat and tooth tip directly affects its service life and stability. High-quality bucket tooth pins have precise matching tolerances to ensure that the bucket teeth can work stably during the excavation process.

- Wear resistance test: By simulating the actual working conditions during the excavation process, the bucket tooth pins are tested for wear resistance to evaluate their service life and performance.

Advantages of GFM excavator bucket teeth pins

GFM excavator bucket teeth pins have the following significant advantages:

- High strength and high wear resistance: Made of high-quality alloy steel, it has excellent mechanical properties and wear resistance, and extends service life.

- Precise matching tolerance: Ensure that the bucket teeth work stably during the excavation process and reduce the failure rate.

- Quick replacement: The well-designed bucket tooth pin is easy to disassemble and install quickly, saving maintenance time and cost.

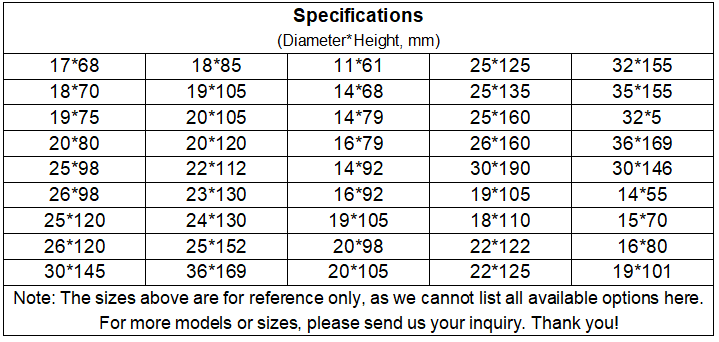

- Diverse choices: According to the different models and working requirements of the excavator, a variety of bucket tooth pins are provided for users to choose from.

How to maintain the excavator bucket tooth pins on a daily basis?

In order to extend the service life of the excavator bucket tooth pins, users should pay attention to the following maintenance measures:

- Regular inspection: Check the wear of the bucket tooth pins regularly and replace them in time if they are severely worn.

- Correct operation: During the excavation process, try to keep the bucket teeth perpendicular to the working surface when digging down to avoid excessive inclination angles that cause the bucket tooth pins to be damaged due to excessive force.

- Reasonable selection of bucket tooth models: Choose the appropriate bucket tooth model according to the working environment to reduce unnecessary wear and damage.

- Keep clean: Regularly clean the dirt and debris around the bucket tooth pins to ensure that the bucket tooth pins can work properly.

Factory Strength Advantages

GFM excavator parts manufacturer, as a leader in the industry, has the following significant strength advantages:

- Advanced production equipment and technology: Introducing internationally advanced production equipment and technology to ensure that product quality reaches the international leading level.

- Strict quality control system: Establish a complete quality control system, from raw material procurement to finished product delivery, every link is strictly inspected and tested.

- Professional R&D team: With a research and development team composed of senior engineers and technicians, it is committed to continuous research and development and innovation to provide users with better products and services.

- Perfect after-sales service system: Provide a complete after-sales service system, including technical consultation, maintenance services, parts supply, etc., to ensure that users receive timely and effective support during use.

As an important part of the excavator, the excavator bucket pin has an important impact on the performance and cost-effectiveness of the excavator. GFM excavator parts manufacturer provides users with efficient and reliable bucket pin solutions with its high-quality products and services. By reasonably selecting and correctly using bucket pins, users can significantly improve the working efficiency of the excavator, reduce maintenance costs, and provide more reliable guarantees for engineering construction.

Email: henry@gfmparts.com

Whatsapp: +86 17705953659