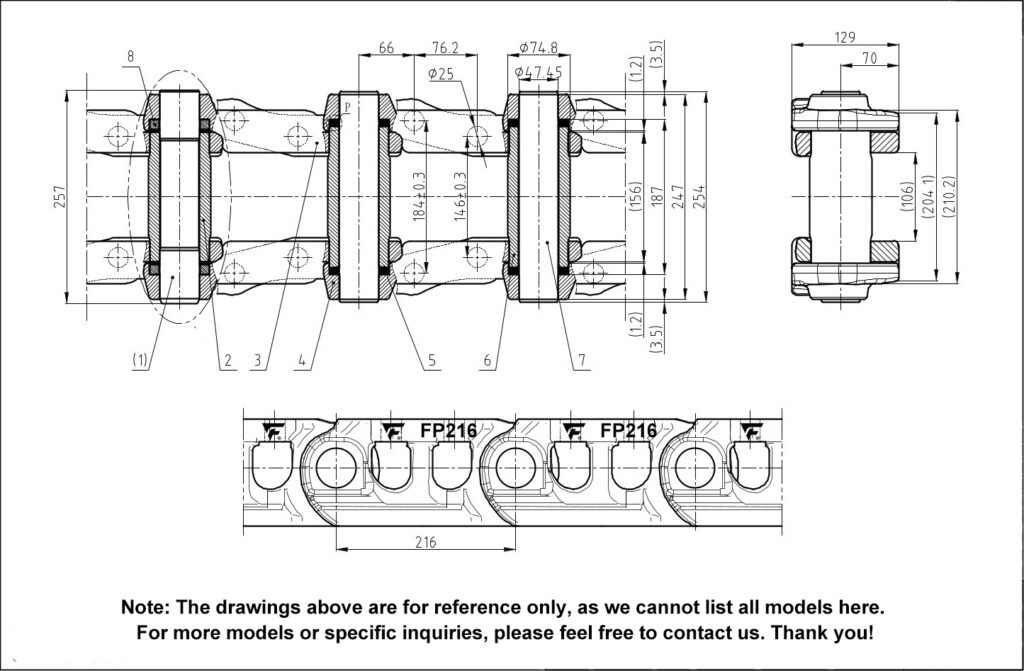

In the operation of the excavator, the track chain and track shoe (track group) are an indispensable part of the chassis system. Their performance directly affects the working efficiency, life and operational stability of the excavator.

Functions and Roles of Excavator Track Group

The Role of Track Chain

The excavator track chain is mainly responsible for transmitting power to the crawler to ensure the movement of the machine. It is the core component connecting the drive wheel and the track shoe, and needs to withstand huge tension and torque.

The Role of Track Shoe

The track shoe contacts the ground, provides traction for the excavator and maintains the stability of the machine. It needs to cope with wear and impact in complex terrain and harsh environments.

Material Selection of Excavator Track Group

High-quality track chain and track shoe are usually made of high-strength alloy steel, and their tensile strength and wear resistance are improved through heat treatment. The following are the key characteristics of both:

Track chain material: should have high hardness and toughness to prevent breakage and premature wear.

Track shoe material: needs to have good corrosion resistance and impact resistance to cope with mud, water and other harsh working conditions.

Common Problems of Excavator Track Group

Improper track chain tension

Problem manifestation: Too loose or too tight track chain will cause the track to fall off or accelerate component wear.

Solution: Check the track chain tightness regularly to ensure that it is within the manufacturer’s recommended range.

Severe track chain plate wear

Problem manifestation: Excessive wear on the chain plate surface will reduce traction and affect driving stability.

Solution: Choose a more wear-resistant chain plate material according to the working conditions, and replace wear parts regularly.

Rusted or broken chain pin

Problem manifestation: Broken or rusted chain pin will cause chain failure and affect the normal operation of the excavator.

Solution: Pay attention to lubrication and cleaning, and avoid long-term exposure to humid environments.

How To Correctly Choose Excavator Track Group

Matchability

Ensure that the specifications of the track chain and track shoe meet the requirements of the excavator model to avoid installation problems or performance degradation due to size mismatch.

Quality certification

Choose suppliers that have passed ISO quality system certification, whose products are more guaranteed in manufacturing process and performance.

Durability test

High-quality track chain and track shoe usually undergo rigorous durability tests to ensure that they can perform well in different working environments.

After-sales service

Reliable manufacturers usually provide comprehensive after-sales support, including installation guidance, daily maintenance recommendations and timely replacement services.

Daily maintenance and maintenance recommendations

Cleaning and lubrication

Regularly clean the sand and impurities on the surface of the track chain and track shoe, and use suitable lubricants to reduce wear.

Tightening inspection

Check the tightness of the chain connection to avoid looseness and chain derailment or poor operation.

Regularly replace wear parts

When the track chain and track shoe are obviously worn or deformed, they should be replaced in time to ensure the performance and safety of the excavator.

Features and Advantages of GFM Factory Track Group

As an industry-leading excavator track chain supplier, GFM factory is committed to providing customers with high quality excavator track shoe. The following are the core advantages of GFM track chains and track shoes:

High-strength materials

GFM track chains and track shoes are made of strictly screened high-strength alloy steel, combined with advanced heat treatment technology, which greatly improves the wear resistance and impact resistance of the products.

Excellent manufacturing process

With the help of automated production equipment and precision processing technology, GFM products have a high degree of consistency and accuracy, ensuring perfect fit with various types of excavators.

Strict quality inspection

Each batch of products undergoes multiple quality inspections, including tensile strength tests, durability tests and corrosion resistance tests, to ensure that the products still perform well in harsh environments.

Customized service

GFM factory provides flexible customized solutions, designs and produces track chain and track shoe according to the specific needs of customers, and meets the special requirements under different working conditions.

High cost performance

GFM products bring customers a higher return on investment with their excellent performance and reasonable price.

As key components of the excavator undercarriage system, the quality and condition of track chain and track shoe directly affect the operating efficiency and service life of the equipment. Through correct selection, installation and maintenance, you can effectively extend the service life of these components and improve work efficiency. If you are looking for high-quality excavator track chain and track shoe, our products will be your ideal choice. Feel free to contact us for more information!

Email: henry@gfmparts.com

Whatsapp: +86 17705953659