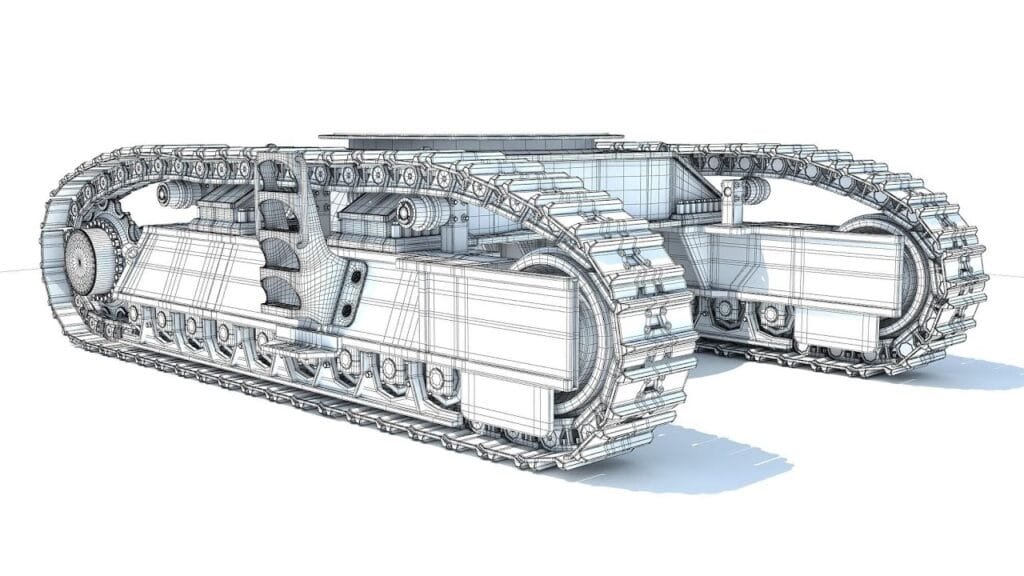

In the construction and engineering industries, excavators and mini excavators have become vital equipment, and the quality of undercarriage parts directly affects the performance and working efficiency of the excavator. As a professional excavator parts manufacturer, GFM provides a series of high-quality, durable and high-performance chassis components to help you improve operating efficiency and reduce maintenance costs.

Are you looking for top parts for your excavator at the best prices? You’ve come to the right place. We are committed to providing exceptional products that offer the best value to our customers. Your satisfaction is our motivation. Email henry@gfmparts.com today and one of our excavator undercarriage experts will be happy to assist you.

Bulldozer Undercarriage and Excavator Undercarriage Part Manufacturer

GFM specializes in providing high-performance excavator and mini excavator undercarriage components to customers around the world, ensuring long-term operation of equipment in harsh environments. Each product is QA inspected and tested to meet and exceed industry benchmarks. Our wide variety of undercarriage parts is sure to get your excavator back on site in no time.

Track Group

Track Link

Track Shoe

Carrier Roller

Track Roller

Sprocket

Track ldler

Digger Buckets

Bucket Teeth

Hydraulic Cylinder

Pin & Bush

Bolt & Nut

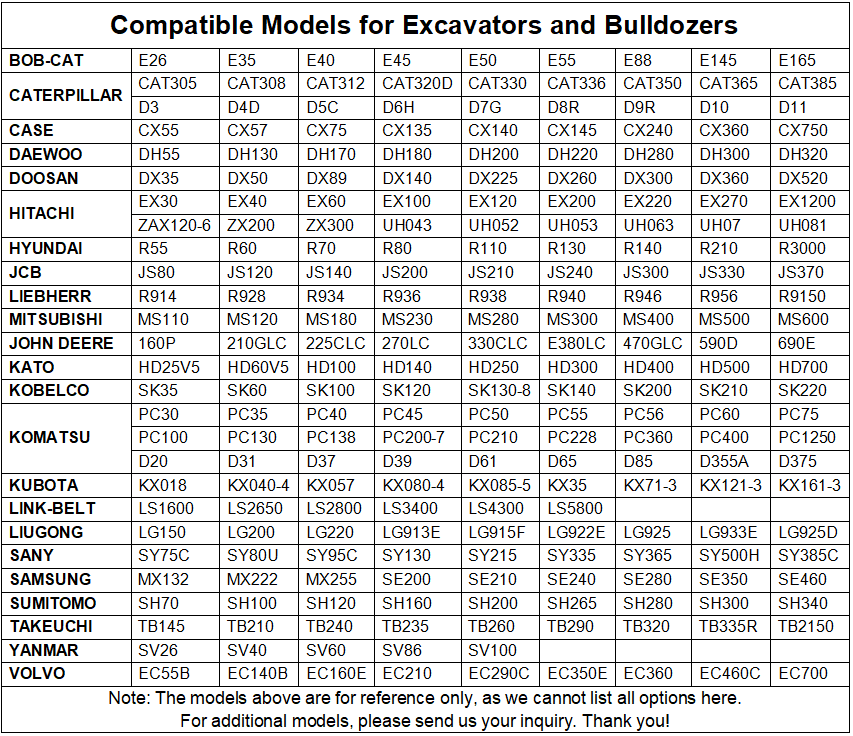

With 14 years of experience, we understand your equipment needs and can help you get the right crawler excavator and dozer undercarriage parts for any model and make.

Advantages of GFM undercarriage parts

- High durability: All GFM chassis components are made of top-quality materials and advanced manufacturing processes, ensuring that they have a long service life and low maintenance frequency.

- Precise adaptation: We offer a wide range of chassis component specifications that can accurately match various excavator and mini excavator models to ensure the perfect fit of the product.

- Strong impact resistance: GFM chassis components are designed to cope with extreme working conditions, ensuring that the equipment can still operate stably in harsh environments.

- Customer customization service: We provide customers with customized services and provide tailor-made chassis solutions according to different usage requirements and working environments.

Provide customers with all-round support

GFM not only provides high-quality bulldozer undercarriage, but also provides customers with comprehensive technical support. Our professional team will provide you with accurate installation guidance, maintenance recommendations and regular product inspection services to ensure that your excavator is always in the best working condition.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Daily inspection of bulldozer and excavator undercarriage part

Track assembly

- Check the tightness of the track: Tracks that are too tight or too loose will affect the stability and operating efficiency of the equipment. Tracks that are too tight will increase fuel consumption, while tracks that are too loose may cause the track to slip or excessively wear.

- Check the wear of the track: Check whether the track is cracked, broken or excessively worn. Timely replacement of severely worn tracks can avoid further damage to other components.

- Check the track guide wheel: whether the guide wheel is loose or worn. The good condition of the guide wheel can effectively guide the movement of the track and prevent the track from being misaligned.

Drive system

- Check the drive wheel: Excessive wear of the drive wheel may cause poor power transmission of the track and affect operating efficiency. Check whether the drive wheel gear is worn or cracked to ensure its normal operation.

- Check the chain and chain plate: The chain is an important part connecting the drive wheel and the track. Check whether the chain is loose, corroded or worn to ensure the tightness and durability of the chain.

Suspension system

- Check springs and shock absorbers: The suspension system of bulldozers and excavators ensures the stability of the chassis. Check whether the springs are deformed, broken or lose elasticity to avoid the stability of the whole vehicle being reduced due to suspension system failure.

- Check the hydraulic system: whether the hydraulic system is leaking or damaged, and whether the hydraulic oil level is normal. Failure of the hydraulic system will directly affect the movement and operating performance of the chassis.

Cab and chassis connection parts

- Check the connection parts between the chassis and the cab: Check whether the fixing bolts between the chassis and the cab are loose, and whether the connecting parts are cracked. Loose connecting parts may cause chassis instability or excessive vibration of the cab.

Lubrication system

- Check the chassis lubrication: Regularly add lubricating oil to the moving parts of the chassis to ensure that the friction between the moving parts is minimized. Check whether the lubricating oil is in good condition and whether there is any leakage.

Daily maintenance of the undercarriage of bulldozers and excavators

Clean the chassis regularly

Clean the dirt, sand and debris on the chassis regularly, which may cause wear to various parts of the chassis or hinder the normal flow of lubricating oil. Cleaning can reduce the occurrence of corrosion and extend the service life of chassis components.

Check fasteners regularly

Check the bolts and fasteners of chassis components to ensure that there are no loose or damaged ones. Loose fasteners may cause equipment vibration and even cause safety accidents.

Lubricate regularly

Regularly lubricate the key moving parts of the chassis, such as tracks, chains, drive wheels, suspension systems, etc., to reduce friction and prevent parts from being damaged due to excessive wear.

Replace worn parts in time

For chassis parts that have been obviously worn or damaged, such as tracks, chains, drive wheels, etc., they should be replaced in time to avoid the spread of faults to other parts.

Check the hydraulic system and lubricating oil

The inspection of the hydraulic system and lubricating oil cannot be ignored. Low hydraulic oil level or poor oil quality will affect the working efficiency and stability of the hydraulic system.

Perform professional inspections regularly

In addition to daily inspections and maintenance, it is recommended to send the equipment to a professional repair station for a comprehensive inspection regularly, especially in the case of heavy loads or long-term high-intensity work. Professional inspections can help discover potential problems and avoid serious damage caused by long-term use.

Equipment chassis maintenance tips

- Avoid excessive load: Overload will cause the chassis to bear excessive pressure and accelerate wear. Ensure that the equipment operates within the designed load range to extend the service life of the chassis.

- Reasonable operation: Operate the equipment smoothly, avoid sudden braking, sudden acceleration and other violent actions, and reduce the impact load on the chassis and other components.

- Regular inspection: In addition to daily inspection and maintenance, comprehensive inspections are carried out at regular intervals, including inspection of chassis components, pressure testing of hydraulic systems, etc., to ensure that the equipment is in good condition.