In the global construction machinery and mining equipment industry, exhibitions are not only platforms for showcasing products and technologies, but also crucial opportunities for companies to expand into international markets and establish partnerships. As a leading Chinese excavator parts manufacturer, GFM recently successfully exhibited at Construction Indonesia and Mining Indonesia. These two exhibitions brought GFM profound market benefits and further demonstrated its production capabilities and international competitiveness.

The Significance of GFM’s Participation in Construction Indonesia

Indonesia is a key country in Southeast Asia for infrastructure construction and mining. With the advancement of the Belt and Road Initiative and increased infrastructure investment by the Indonesian government, demand for construction and mining equipment is growing rapidly.

Construction Indonesia, Southeast Asia’s most influential construction and construction machinery exhibition, brings together leading global construction machinery manufacturers, parts suppliers, and construction companies.

Mining Indonesia, the largest international mining exhibition in the Asia-Pacific region, focuses on mining equipment, parts, and solutions, making it a vital platform for mining buyers to find reliable suppliers.

GFM’s participation in both major exhibitions not only demonstrates the company’s commitment to the Southeast Asian market, but also demonstrates its strong capabilities and comprehensive solutions in both the construction and mining sectors.

Exhibit Highlights and Buyers’ Focus

At the exhibition, GFM showcased a variety of its core excavator accessories and undercarriage components, including:

- Excavator track shoes and track assemblies

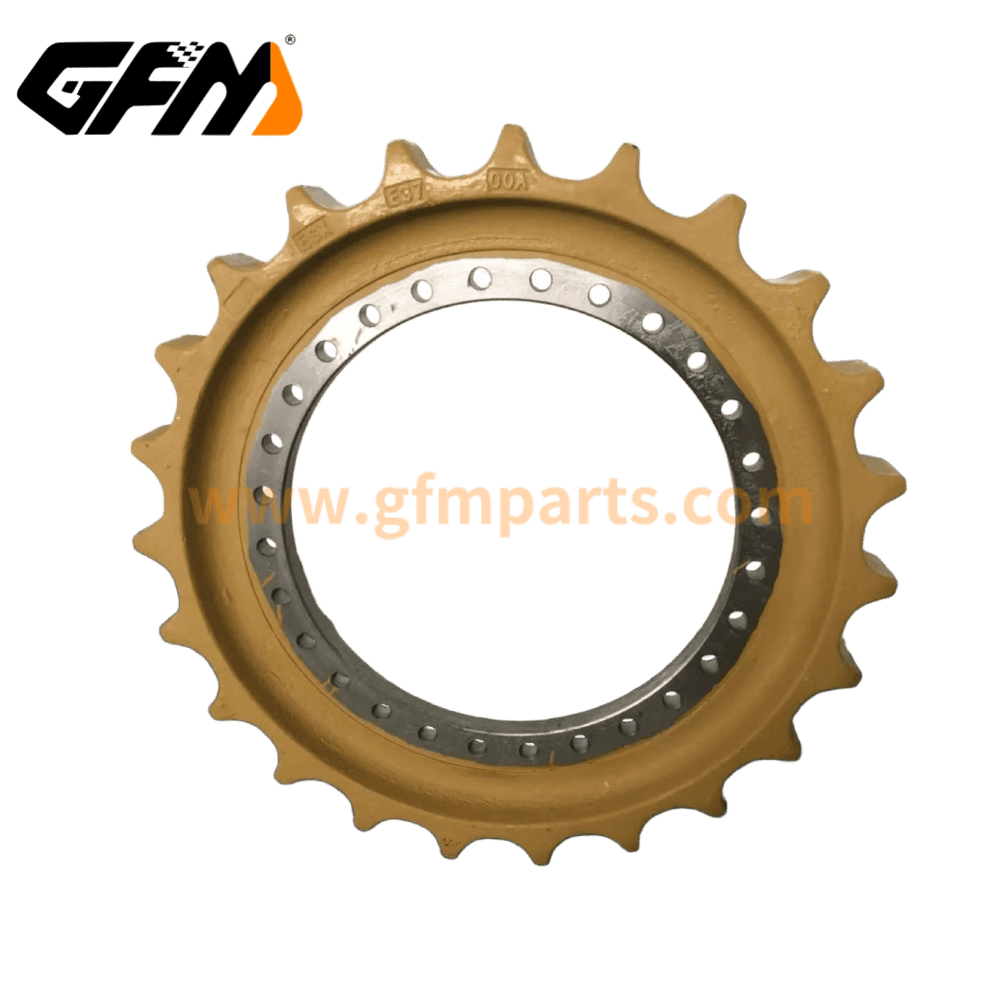

- Roller, idler, and sprocket components

- Wear-resistant parts such as bucket shafts and bushings

These products are designed and optimized for the humid, hot, and high-wear, high-intensity working environments found in Southeast Asia’s mining areas, attracting a large number of buyers.

Common concerns among buyers included:

- Product durability – In mining and infrastructure projects, component lifespan directly impacts downtime costs.

- Supply stability – Customers in Indonesia and surrounding markets prefer manufacturers with stable delivery cycles and comprehensive after-sales service.

- Customization capabilities – Many customers requested custom materials or sizes based on their specific application requirements.

- Balancing Price and Value – Buyers not only compare prices but also prioritize product lifecycles and total cost of ownership (TCO).

Leveraging years of international market experience, the GFM team provided professional answers and showcased real-world case studies, earning high recognition from customers.

GFM’s Key Takeaways from the Expo

GFM not only showcased its products but also gained multi-faceted market feedback and partnership opportunities.

Expanding Customer Repository

During the exhibition, GFM welcomed buyers from Indonesia, Malaysia, the Philippines, Thailand, and the Middle East. Some clients have expressed interest in collaborating, and long-term supply relationships are expected.

Enhancing Brand Internationalization

The exhibition significantly boosted GFM’s brand awareness in the Indonesian and Southeast Asian markets. Through on-site demonstrations and sample displays, buyers shifted their perception of “Made in China” from “price advantage” to “high quality and value for money.”

Factory Strength: The Core of GFM’s Competitive Advantage

Exhibitions are a showcase, but the key to truly impressing customers lies in the comprehensive strength of the factory. As a professional excavator undercarriage parts manufacturer, GFM boasts several key advantages:

Full-Process Production and Strict Quality Control

GFM’s factory is equipped with advanced CNC machine tools, heat treatment equipment, and automated production lines. From raw material selection to finished product testing, we adhere to ISO 9001 quality management system standards.

- Raw Material Testing: We rigorously select high-strength alloy steel and wear-resistant materials.

- Process Control: We utilize multiple heat treatment processes, including quenching and tempering, to ensure product strength and toughness.

- Finished Product Testing: Each batch undergoes hardness, tensile, impact, and wear resistance testing.

A Comprehensive Product Line to Meet Diverse Needs

GFM not only offers standard parts but also offers OEM/ODM customization. Whether it’s for mainstream international models like Caterpillar, Komatsu, Hitachi, and Doosan, or custom parts for specialized operating environments, we can respond quickly.

Fast Delivery and Stable Supply

GFM’s extensive warehousing and logistics network ensures fast delivery of bulk orders. For the Southeast Asian market, the factory has established a dedicated logistics channel to shorten shipping cycles and reduce procurement risks for customers.

Technological Innovation and R&D Capabilities

The factory has an independent R&D center, continuously pursuing breakthroughs in materials science and process technology. For example:

- Using a new alloy steel formula to improve wear resistance.

- Applying surface enhancement technology to track shoes and bucket teeth to extend service life.

- Developing an environmentally friendly coating process to reduce environmental impact.

International Cooperation and Service Guarantee

GFM has extensive experience in overseas cooperation, providing technical support, installation guidance, and after-sales service to customers around the world. This allows buyers to not only purchase products but also receive complete solutions.

Looking Forward: GFM’s International Development Path

Participating in the Construction Indonesia and Mining Indonesia exhibitions is a key step in GFM’s internationalization strategy. Going forward, GFM will continue to:

- Increase investment in the Southeast Asian market – plans to establish a long-term cooperative warehousing location in Indonesia to shorten delivery cycles.

- Continue to research and develop new products – developing more high-performance accessories tailored to different mining areas and construction environments.

- Strengthening the after-sales service network – collaborating with local partners to provide rapid repair and spare parts support.

- Expanding the global market – In addition to Southeast Asia, GFM also plans to increase market development in South America, the Middle East, and Africa.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

GFM’s successful appearance at the Construction Indonesia exhibition not only showcased its product strengths and factory advantages, but also provided a deeper understanding of market demand through practical exchanges and partnership opportunities, laying a solid foundation for its future international expansion.

As a professional excavator parts manufacturer, GFM will continue to adhere to high-quality production, continuous innovation, and global service to provide reliable construction machinery solutions to customers worldwide. In the future, GFM is determined to exert greater influence on the international stage and contribute to the successful implementation of more engineering and mining projects.