Table of contents

GFM’s Industry Experience and Manufacturing Strength

In the construction machinery industry, excavators and bulldozers operate under high-load, high-impact, and high-wear conditions for long periods, and the stability of parts directly affects equipment lifespan and operating costs. Therefore, choosing a reliable excavator parts manufacturer is a crucial consideration for equipment users and parts buyers.

GFM has been dedicated to the manufacturing of construction machinery parts since its establishment in 2011, accumulating 14 years of industry experience and continuously focusing on excavator and bulldozer undercarriage components.

The manufacturing strength of GFM is mainly reflected in the following aspects:

- 15 years of specialized experience in undercarriage parts manufacturing: Since its inception, GFM has focused on high-wear and high-load undercarriage components such as carrier rollers, idlers, track rollers, sprockets, track shoes, track chains, and track assemblies. Serving real engineering conditions over the years, the factory has accumulated mature experience in structural design, material application, and durability control.

- Comprehensive product range and supply capability: GFM has established a product system covering more than 1,000 commonly used part models, meeting the replacement needs of different machine types and applications. With complete inventory and production planning, the factory can provide stable supply for long-term cooperation and bulk purchases.

- Modern factory with forging and automated equipment: GFM operates a production base equipped with casting, forging, and automated processing capabilities, covering key processes such as forming, machining, heat treatment, and assembly. Through coordinated equipment and standardized procedures, product consistency and stability are effectively ensured.

- Strict raw material and heat treatment management: For high-load operating conditions of construction machinery, GFM strictly selects raw material sources and configures heat treatment schemes based on the stress characteristics of different components, maintaining a balanced combination of strength, toughness, and wear resistance.

- Mature compatibility with mainstream brands: GFM products are widely compatible with mainstream brands such as Komatsu, Hitachi, Caterpillar, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kubota, Bobcat, Yanmar, Sany, Liugong, XCMG, Shantui, ensuring stable assembly fit and structural reliability.

Comprehensive Excavator Parts Series

Focusing on the high-wear and high-load characteristics of excavators and bulldozers in practical construction, GFM has built a complete product system covering key stress and wear-prone areas, demonstrating the depth of a mature excavator parts supplier in product planning and manufacturing.

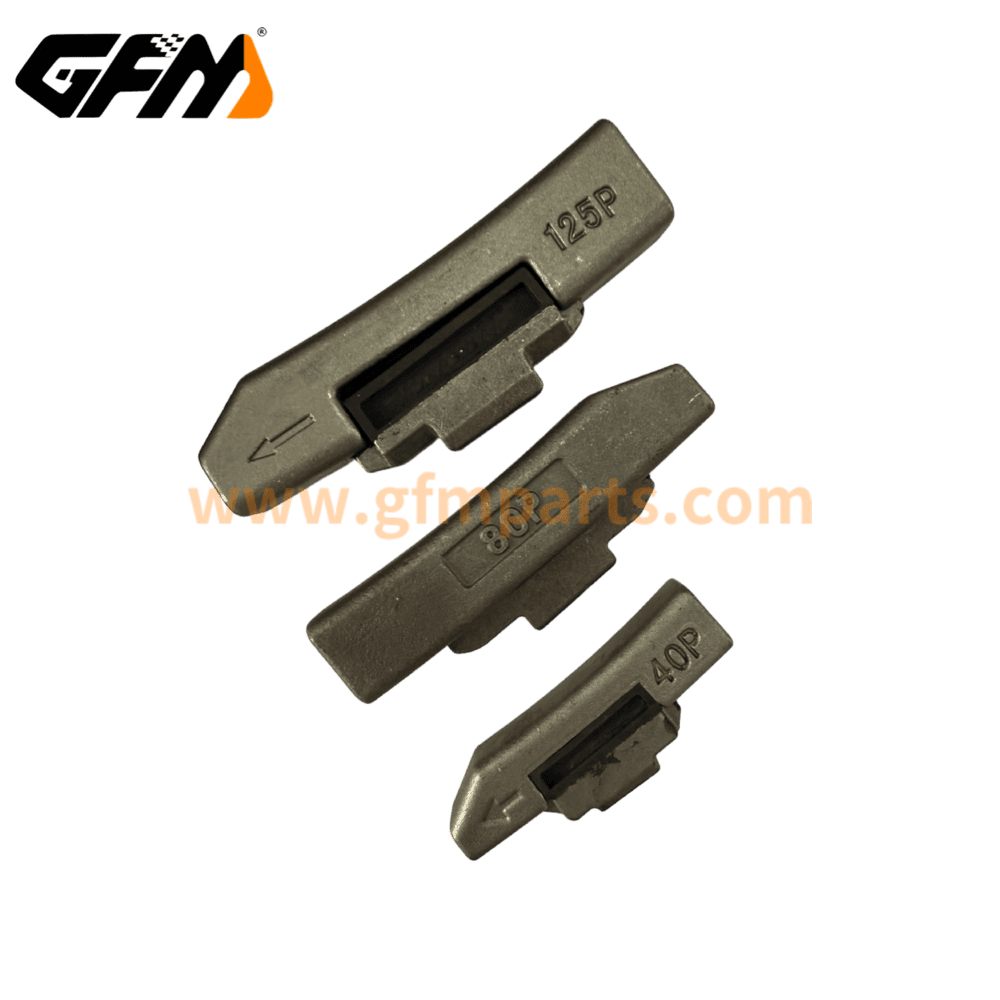

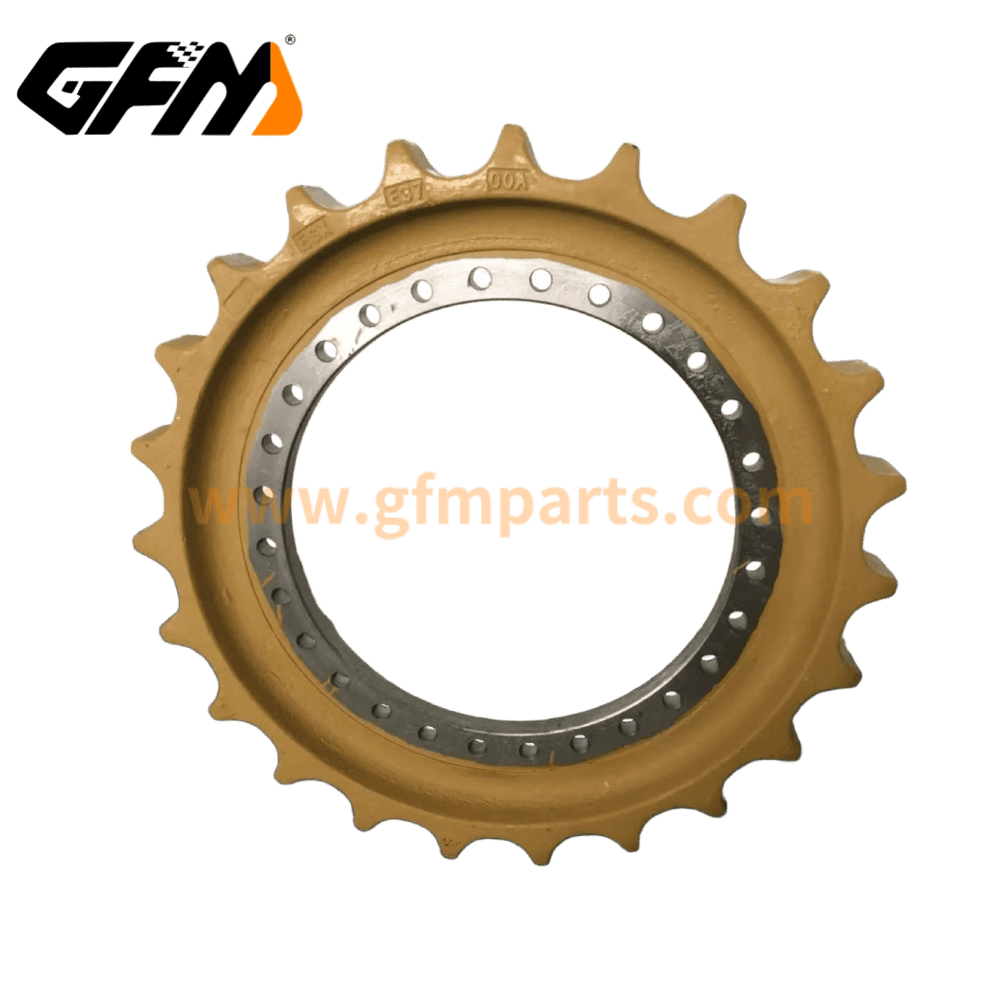

- Core undercarriage components: GFM’s core products include carrier rollers, idlers, track rollers, sprockets, track shoes, track chains, and track assemblies. These components directly bear the weight of the machine and endure long-term impact loads. With mature processes and long-term verification, the products can adapt to complex construction environments.

- Fasteners and connecting components: The factory also supplies bolts, nuts, pins, and bushings. Although small in size, these components directly affect the structural safety of the machine. GFM focuses on dimensional accuracy and assembly stability in the manufacturing process.

- Bucket and wear part support: For parts with high replacement frequency during construction, GFM provides bucket pins, chain pins, and bushings to meet equipment maintenance and bulk replacement needs.

- Mainstream brand model compatibility: Based on years of accumulated model data, GFM’s products demonstrate stable assembly fit, effectively reducing installation and adjustment costs.

- Complete inventory for bulk supply: For high-frequency models, GFM maintains a stable inventory structure to support fast delivery and continuous supply, suitable for distributors and long-term project cooperation.

GFM’s Professional Manufacturing Advantages Across Components

- Structural reinforcement experience for load-bearing and travel components: For load-bearing components such as carrier rollers and idlers, GFM emphasizes long-term fatigue performance, reducing deformation and fracture risks through reasonable design and heat treatment.

- Consistency control for track system components: For high-wear parts such as track shoes and track chains, GFM focuses on material performance and machining consistency, ensuring stable performance across batches.

- Precision and reliability management for connecting components: Pins, bushings, and similar parts maintain dimensional stability and surface treatment to enhance long-term reliability.

- Balance of lifespan and maintenance for wear parts: GFM considers both wear life and replacement convenience in the production of consumable parts, reducing long-term maintenance costs.

- Integrated manufacturing logic based on application scenarios: All components are manufactured based on real working conditions, balancing strength, wear resistance, and stability.

Advanced Manufacturing Processes and Technology

As a professional excavator parts manufacturer, GFM regards manufacturing processes as the core foundation of product reliability, establishing a mature system around materials, structure, and lifespan.

- Raw material selection and front-end quality control: Raw materials are screened and verified before production to ensure basic performance meets manufacturing requirements.

- Differentiated casting and forging processes: Depending on component structure and stress characteristics, casting or forging processes are selected to balance performance and cost.

- Systematic heat treatment process: Standardized quenching and tempering optimize component hardness and toughness, improving service life.

- Machining and dimensional consistency control: Multiple machining processes ensure critical dimensions remain stable, maintaining assembly consistency across batches.

- Process inspection and monitoring: Process checks and final inspections ensure products meet established quality standards.

Mainstream Brand Compatibility and Application Scenarios

GFM’s parts cover key stress and wear components while demonstrating mature experience in brand compatibility and practical engineering applications. Long-term engineering practice has created professional advantages in part fit and operational optimization.

- Wide compatibility with mainstream excavator and bulldozer brands: Products fit brands such as Komatsu, Hitachi, Caterpillar, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kubota, Bobcat, Yanmar, Sany, Liugong, XCMG, and Shantui. Years of model data and working condition analysis ensure assembly fit, structural strength, and durability meet original equipment standards.

- Coverage of multiple machine types and engineering applications: Components are widely used in mining, earthmoving, municipal construction, roadwork, and large infrastructure projects. Each machine type has different stress distribution and wear patterns. GFM optimizes material selection, heat treatment parameters, and geometry to ensure performance stability under complex conditions.

- Reliability verified by engineering practice: Long-term use in domestic and overseas projects has provided abundant test data, including wear cycles, load limits, and fatigue life. Based on this data, GFM optimizes design and production processes to ensure high reliability under heavy-duty operations.

- Inventory management and rapid matching capability: High-frequency models are stocked adequately. With batch management and traceability, customers can quickly obtain required parts, reducing equipment downtime while ensuring product consistency.

- International supply experience and adaptability: GFM’s parts have been exported to multiple countries and regions, covering Asia, Africa, Europe, and the Middle East. Components are optimized for different local construction standards, climate conditions, and soil characteristics to maintain stable performance worldwide.

Quality Assurance and Certification System

GFM regards quality management as a core competitive advantage, establishing a complete quality system and certification process to ensure every part meets the highest standards of performance, reliability, and durability in the construction machinery industry.

- Systematic quality management system: From raw material procurement, forging or casting, heat treatment, machining, to final inspection, GFM has a full-process quality control system. Each stage has strict process specifications and inspection standards to ensure parts meet design requirements and long-term stability.

- High-precision inspection equipment and process control: The factory is equipped with CMMs, hardness testers, metallographic microscopes, and wear testing devices to monitor critical dimensions, hardness, internal structure, and wear resistance. Multi-stage inspections ensure batch consistency and repeatability.

- Authoritative certifications and industry recognition: Products have obtained ISO quality management system certification and related mechanical industry standards certifications, verifying process compliance and product reliability, providing customers with authoritative quality assurance.

- Traceability and factory quality guarantee: Every part has complete batch records, including raw material sources, production parameters, heat treatment records, and inspection data. Customers can trace product information throughout its lifecycle, achieving supply chain transparency and controllable risk.

- Continuous improvement and reliability optimization: Based on long-term engineering feedback, GFM continuously improves manufacturing processes and inspection methods. By analyzing wear cycles, fatigue strength, and field usage data, part design and production parameters are gradually optimized, enhancing overall reliability and service life.

- Quality system combined with global supply capability: Through standardized production and strict quality control, GFM can provide stable, high-quality parts to global markets. Whether for domestic projects or overseas applications, customers can obtain parts that meet standard requirements, reflecting GFM’s professional manufacturing and global supply capabilities.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

With 14 years of professional accumulation since 2011, GFM has become an industry-leading excavator parts manufacturer and excavator parts supplier. From core undercarriage components to bolts, pins, and bushings, every product undergoes strict manufacturing processes, advanced heat treatment, and multiple inspections to ensure excellent performance under high-load, high-wear engineering conditions.

By being compatible with mainstream brands, covering various engineering scenarios, and establishing a systematic quality management and traceability system, GFM provides stable and reliable parts not only for domestic clients but also for international markets. Whether in mining, earthmoving, or municipal construction projects, GFM parts meet high engineering standards, enhancing equipment efficiency and lifespan. Choosing GFM means choosing a professional, stable, and reliable partner for construction machinery parts.