Table of contents

- What is an excavator bucket pin? Why is it so important?

- Common types of excavator bucket pins and their application scenarios

- Manufacturing standards for high quality bucket pins: materials, processes and testing

- Five advantages of GFM as China’s top bucket pin manufacturer

- Practical guide to installation and maintenance of excavator bucket pins

- Customized service and cooperation process of GFM bucket pin

- Customer success case sharing: Why do global customers trust GFM?

What is an excavator bucket pin? Why is it so important?

Among the various key components of an excavator, the excavator bucket pin (also known as the bucket ear pin, connecting pin) is not large in size, but it plays a vital role. The bucket pin mainly connects the bucket ears of the excavator with the boom, dipper rod and other structural parts, and is an indispensable connection hub in the entire bucket movement.

Every time the bucket is excavated, tipped, lifted or unloaded, the bucket pin bears great mechanical pressure and impact load. It can be said that the bucket pin not only determines the flexibility of the bucket movement, but also directly affects the efficiency and operating life of the entire equipment.

If the quality of the bucket pin is not up to standard, it may cause the bucket to loosen, the fit gap to expand, and even the risk of structural fracture, which will bring serious hidden dangers to operation safety and equipment maintenance. Therefore, whether it is a complete machine manufacturer or an equipment maintenance company, when choosing a bucket pin, it should attach great importance to its manufacturing quality, material selection and precision control.

Common types of excavator bucket pins and their application scenarios

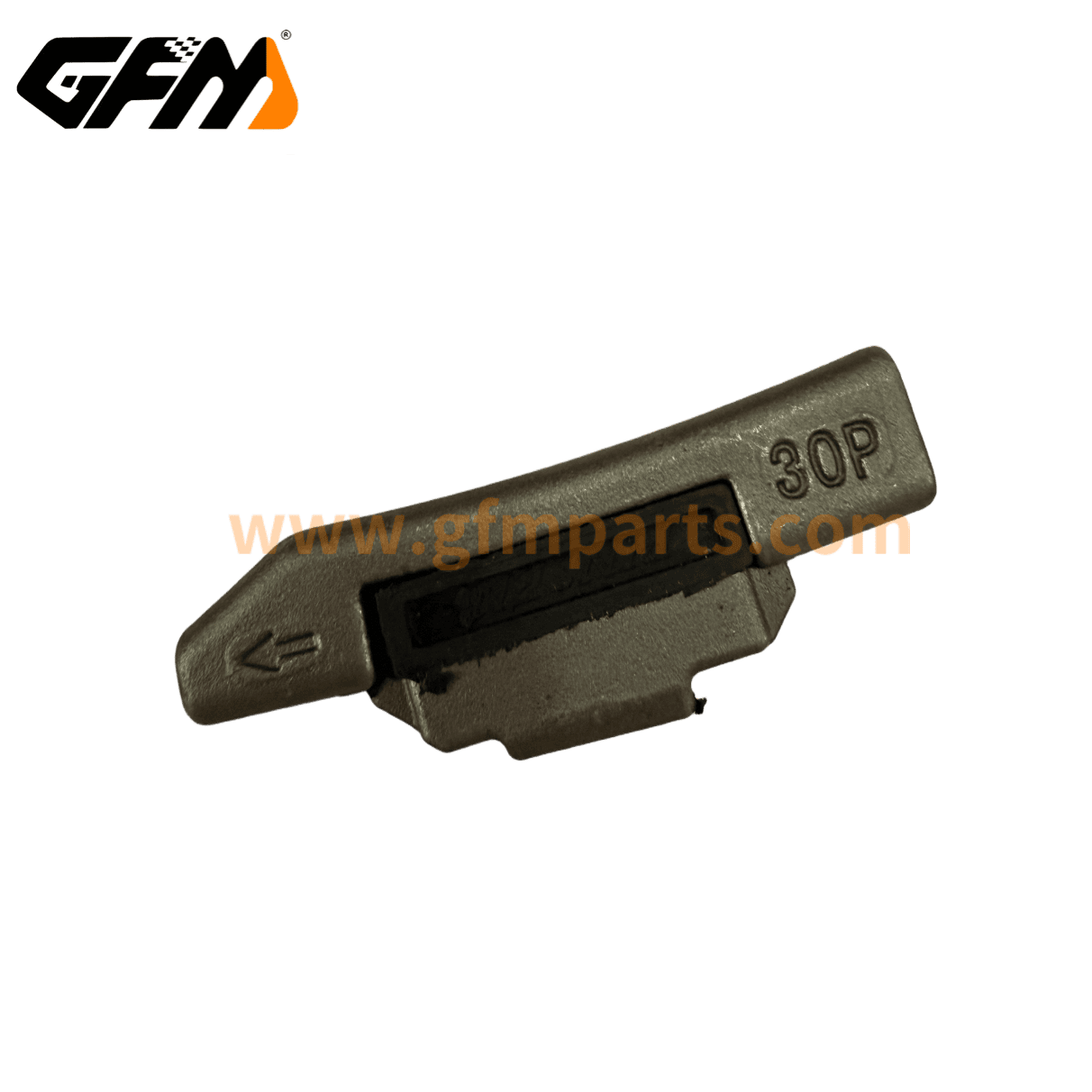

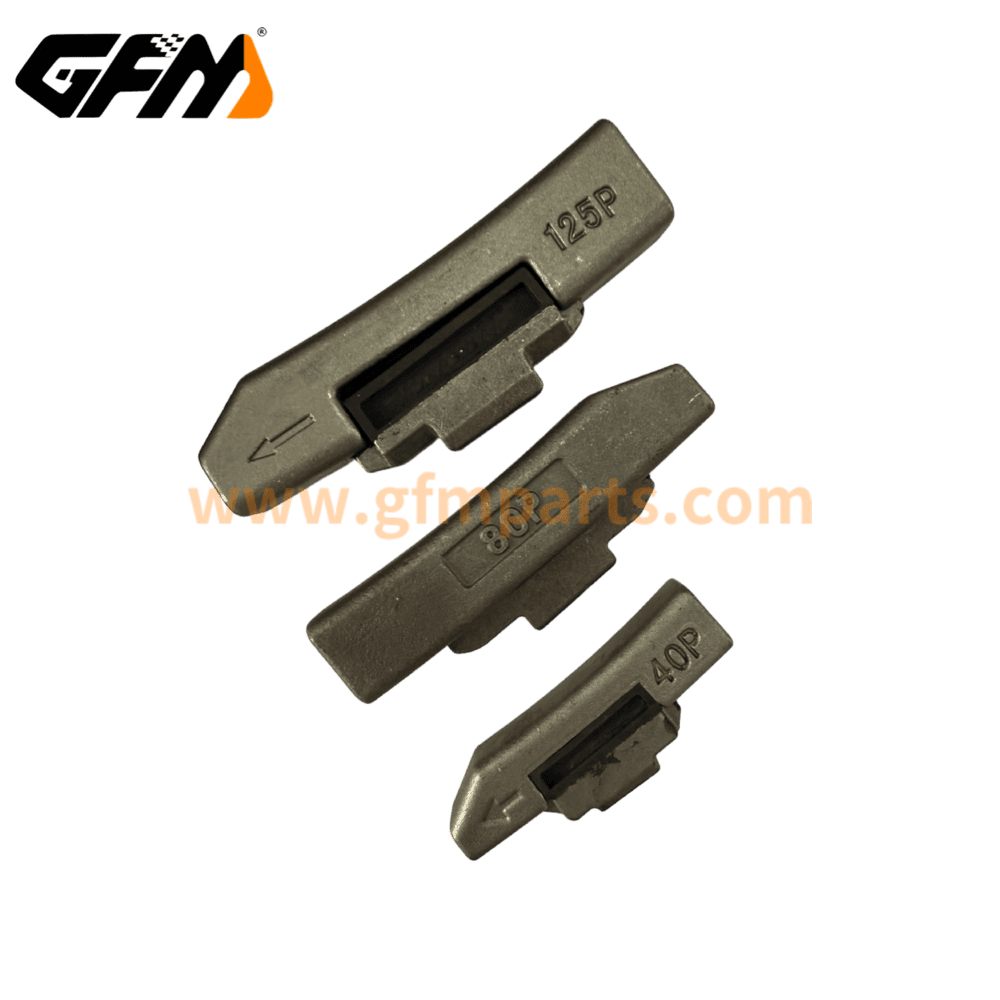

According to different models, working conditions and load requirements of the equipment, bucket pins are divided into many types in actual applications. The most common ones are mainly the following categories:

Standard bucket pin

Standard bucket pin is suitable for small and medium-sized excavators, and common specifications include 80×400mm, 90×500mm, etc. This type of bucket pin is suitable for medium-intensity working conditions such as urban infrastructure construction, earthwork excavation, and ditch finishing. It has the advantages of moderate cost, strong compatibility, and easy replacement.

Reinforced bucket pin

Reinforced bucket pin is often used in heavy machinery and equipment. It is designed for high-intensity working environments (such as mines and stone yards). It is usually made of high-strength alloy steel materials, and the surface is quenched to have higher compression and torsion resistance. This type of bucket pin has a long service life and wear resistance, and is suitable for high-frequency, high-load, and high-wear environments.

Non-standard customized bucket pin

For some customers’ customized equipment or imported excavators, standard bucket pins are difficult to fully match, so non-standard customization is required according to drawings, samples or interface requirements. This type of bucket pin emphasizes personalized matching and is generally produced in small batches, especially suitable for OEM/ODM customers.

Special operation bucket pin

Some operating environments (such as deep-sea operations, high-cold areas, and corrosive environments) have special requirements for bucket pin materials and coatings. GFM can provide bucket pins with anti-corrosion treatment, stainless steel or ultra-low temperature materials to meet diverse application needs.

Manufacturing standards for high quality bucket pins: materials, processes and testing

The manufacturing of high-quality bucket pins is inseparable from strict standard control, which is mainly reflected in three aspects: material selection, process flow and testing methods.

Material selection

GFM uses high-quality 45# steel, 40Cr, 35CrMo alloy steel, etc. as the main raw materials. These steels have good mechanical strength and toughness. After quenching and tempering, the hardness and ductility reach the standards suitable for heavy-duty environments.

Some heavy-duty bucket pins use forged blanks to improve the density and internal structural stability of the pin body from the source and reduce the risk of microcracks.

Process flow

GFM uses high-precision CNC machine tools for processing to ensure that the concentricity, fit tolerance and surface finish of both ends of the bucket pin meet the 0.01mm level standard. Surface heat treatment includes high-frequency quenching and tempering treatment, and the hardness range is controlled between HRC 48 and 55, which effectively improves wear resistance.

For bucket pins for special applications, GFM can also provide a variety of surface treatment solutions such as chrome plating, zinc spraying, and phosphating treatment to enhance corrosion resistance.

Inspection and control

Before each bucket pin leaves the factory, GFM must undergo dimensional inspection, hardness inspection, coaxiality inspection, ultrasonic flaw detection and other processes. All products are accompanied by inspection reports and strictly follow the ISO9001 quality system and GB/T mechanical standards to ensure the safety and reliability of each bucket pin.

Five advantages of GFM as China’s top bucket pin manufacturer

Rich industry experience: GFM has 14 years of experience in manufacturing engineering machinery structural parts such as bucket pins, bucket teeth, and track parts, serving more than 100 customers, covering multiple complete machine brands at home and abroad.

Strong production capacity: self-built 10,000 square meters of modern factory, introduced a number of high-precision CNC processing equipment, heat treatment lines, forging lines, annual production of more than 100,000 bucket pins.

Technical support capabilities: With a professional design team, we can quickly customize and optimize the structure according to customer drawings or samples, provide supporting suggestions, and help customers solve practical application pain points.

Perfect quality management system: strictly implement ISO9001 standards, implement full process quality control (IQC, IPQC, FQC, OQC), and ensure that every product meets the standards.

Export and certification capabilities: GFM products are exported to Southeast Asia, South America, the Middle East, Africa and other regions, and have been highly recognized by many international customers. At the same time, it has multiple export qualifications such as CE and SGS.

Practical guide to installation and maintenance of excavator bucket pins

In order to ensure the stability of bucket pins in actual work, correct installation and daily maintenance are very important. The following is a practical operation guide recommended by GFM:

Installation steps:

- Preparation stage: Clean the pin hole and ear plate to ensure that there are no impurities and burrs, and check whether they are deformed.

- Positioning and assembly: Use a sling or bracket to assist in positioning to avoid eccentric assembly.

- Pressing or insertion: Select hydraulic press-fitting or manual installation depending on the bucket pin structure. Be careful not to knock to cause deformation of the pin.

- Lubrication addition: Fill the lubrication hole with lithium-based grease to fill the lubrication groove.

- Fixed inspection: After installation, check whether the pin rotates smoothly and whether there is any jamming or abnormal noise.

Daily maintenance tips:

- The lubrication should be checked every 100 hours of work and replenished if necessary.

- The pin should be checked for looseness before and after each use.

- Check the wear of the mating parts regularly. If the mating clearance exceeds 1mm, it is recommended to replace it.

Customized service and cooperation process of GFM bucket pin

As a manufacturer with many years of OEM/ODM experience, GFM provides customers with one-stop bucket pin customization service:

Customization process:

Customers provide drawings or samples to clarify parameters such as material, size, working conditions, etc.

- GFM conducts feasibility assessment and solution suggestions to optimize structural details.

- Prototype confirmation: Sample production is completed within 7 days and sent to customers for confirmation.

- Mass production: Quick production after signing the production contract, with stable delivery cycle.

- After-sales follow-up: Provide installation guidance, technical support and maintenance suggestions.

GFM can provide various bucket pins with sizes ranging from Ø40mm to Ø120mm and lengths up to 1000mm, meeting the full range of equipment needs for small, medium and large excavators.

Customer success case sharing: Why do global customers trust GFM?

- A large engineering machinery agent in Vietnam: The original bucket pins were frequently broken, which led to customer complaints. After switching to GFM customized products, the failure rate dropped by more than 90%, and customer satisfaction was significantly improved.

- Customized case of South American mining equipment manufacturers: In a high-wear environment, GFM recommends that customers use a reinforced forged bucket pin + chrome plating solution, which extends the actual service life from 8 months to 18 months, saving more than 40% of maintenance costs.

- Cooperation with OEM manufacturers in the Middle East: The customer needs to supply 30,000 bucket pins annually, and GFM customizes production molds + stable delivery plans for it. The current cooperation has lasted for more than 5 years and is continuing to expand.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Although the bucket pin is small, it carries the key tasks of the entire excavation operation. Choosing a high-quality bucket pin can not only improve equipment performance and reduce maintenance costs, but also fundamentally ensure engineering efficiency and safety.

As China’s leading bucket pin manufacturer, GFM not only has a mature technical team and strong processing capabilities, but also has won the recognition of global customers with stable quality and professional services.

If you are looking for a high-quality, customizable, and stable delivery bucket pin partner, GFM is a trustworthy choice. Welcome to contact us for samples or customized quotes to start a win-win cooperation.