Table of contents

What Are Excavator Track Shoes?

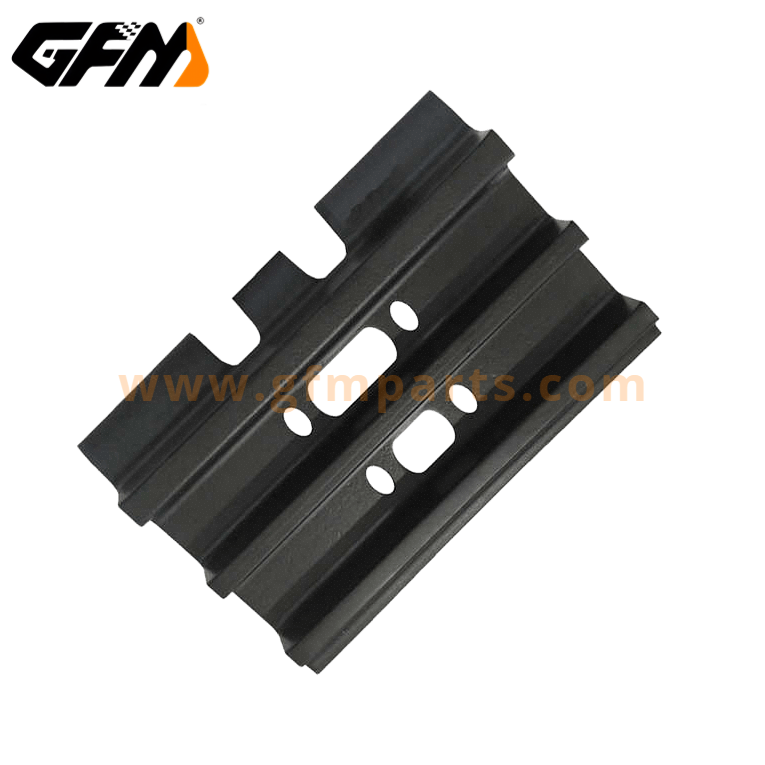

In tracked construction machinery like excavators, the excavator track shoe is a critical component of the undercarriage system. It connects the track links to the ground, ensuring stability, load-bearing, and traction. Its wear resistance and structural strength directly affect the machine’s efficiency and lifespan in complex operating environments.

Core Functions of Track Shoes:

- Load Bearing: Distributes the machine’s weight to reduce ground pressure.

- Traction Support: Enhances grip on slippery, soft, or rugged surfaces.

- Impact and Wear Resistance: Protects the track links and undercarriage.

- Stability: Reduces risks of slippage and deviation.

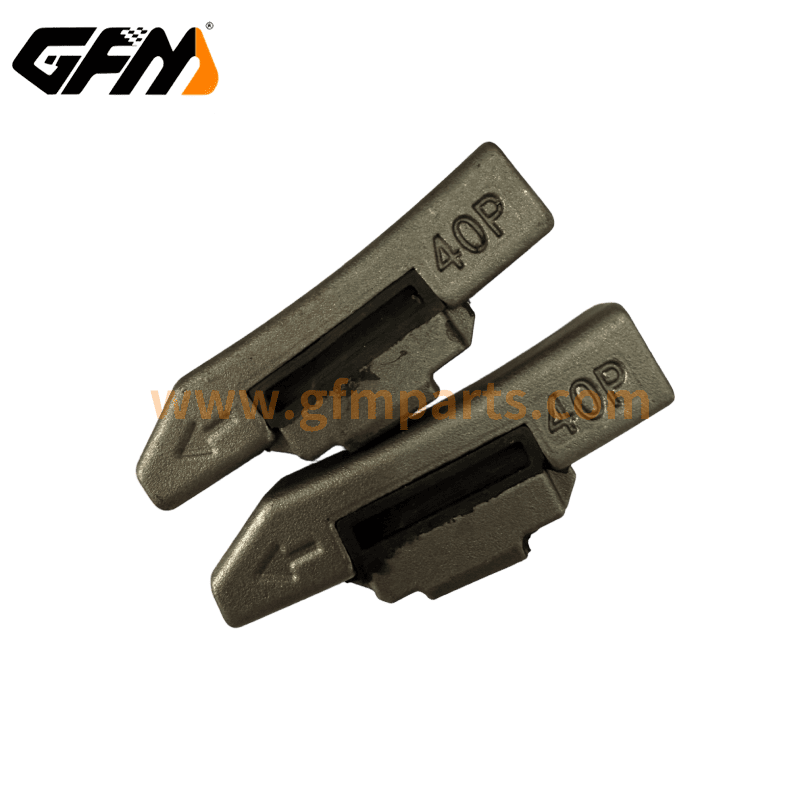

Track Shoe Classifications:

- By Grousers: Single (high grip for soft ground), Double/Triple (balance between stability and maneuverability).

- By Use: Steel track shoes (durable for mines/construction), rubber track shoes (for urban roads or landscaping).

- By Structure: Forged single-body, welded combo, and bolt-on replaceable types.

Material Standards: High-quality excavator track shoes are typically made from boron-manganese steel or medium-carbon alloy steel such as 35MnB and 40SiMnTiB. GFM ensures the selection of certified materials and applies precise heat treatment based on operational scenarios to guarantee hardness, toughness, and crack resistance.

Are you looking for quality track shoe at the best price? You have come to the right place. We are committed to providing excellent products and offering the best value to our customers. Your satisfaction is our motivation. Send an email to henry@gfmparts.com now and our excavator undercarriage parts experts will be happy to serve you.

GFM’s Manufacturing Strength

Founded in 2011, GFM is a professional excavator track shoe manufacture specialist with full in-house production capabilities. From material storage, forging, heat treatment, CNC machining, to final inspection, each step is meticulously controlled.

Factory Capabilities:

- Based in Quanzhou, Fujian, China.

- 5000+ sqm factory space with modern production lines.

- Equipped with hydraulic forging presses, heat treatment furnaces, CNC machines.

- Independent QC center with hardness testers, metallographic analyzers, and dimensional projectors.

Production Process:

- Raw Material Inspection & Cutting: Alloy steel is tested for composition and structure.

- Forging: Closed-die forging improves metal density and crack resistance.

- Heat Treatment: Quenching + tempering ensures surface hardness and inner toughness.

- CNC Machining: Precise positioning holes and mounting features are finished.

- Surface Protection: Shot blasting, painting, phosphating, or plating per customer needs.

Quality System: GFM is ISO 9001 certified. It implements full traceability and SPC quality control checkpoints. Custom QC reports are available for OEM clients.

GFM’s Professionalism and Authority in Global Markets

With years of technical accumulation and quality practice, GFM’s track shoes consistently meet international heavy equipment standards. The goal isn’t just qualified production—it’s long service life, low maintenance, and superior adaptability.

Global Standards Compliance:

- Dimensional specs align with brands like Komatsu and Caterpillar.

- Heat-treated surface hardness: HRC 50–56.

- 100% appearance inspection and randomized mechanical testing before shipment.

High Compatibility: Over 1,000 models are available, compatible with:

- Komatsu, Hitachi, Caterpillar, Volvo, Hyundai, Doosan, SANY, XCMG, Shantui, Kobelco, Yanmar, Bobcat, and more.

Applications span construction, mining, ports, wetland reclamation, and beyond. GFM is the long-term partner for many global distributors and service centers.

GFM’s Technical Advantages in Track Shoe Manufacturing

GFM’s competitiveness lies not just in scale but in its refined manufacturing craft. Continuous optimization of processing details results in track shoes with excellent wear resistance, fatigue life, and uniform stability.

Advanced Heat Treatment:

- Proprietary temperature control curves per thickness/shape.

- Balanced hardness outside, toughness inside.

- Fracture rates well below industry averages.

High-Strength Forging:

- One-piece forging avoids weld-induced fatigue cracks.

- Denser metal structure, higher tensile and compressive strength.

- Greater product uniformity.

Anti-Corrosion Surface Treatment:

- Combined shot blasting, phosphating, and coating.

- Optional salt-spray resistance, high-humidity anti-rust, and noise-reduction coatings.

GFM’s Application Expertise: Track Shoes for Every Jobsite

Different working conditions call for different track shoe designs. With 14 years of experience, GFM provides customized solutions across industries and terrains.

Adaptation Scenarios:

- Mining/Quarries: Manganese triple-grouser for impact and self-cleaning.

- Farmland/Wetlands: Wide double-grouser for low ground pressure.

- Urban Use: Rubber pads reduce road damage and noise.

- Cold Regions: Special heat treatment resists low-temperature cracking.

Support Services:

- Model recommendation, CAD drawing support, installation guidance.

- 3,000+ SKUs in stock for fast delivery.

- Custom packaging, branding, and OEM options for distributors and service centers.

Industry Trends and GFM’s Sustainable Innovation

Excavator track shoe manufacturing is evolving toward automation, eco-friendliness, and smart production. GFM actively integrates new technologies to ensure long-term sustainability while maintaining product excellence.

Industry Directions:

- Lightweight designs for better fuel efficiency.

- Recyclable materials to reduce carbon footprint.

- Digitalized selection systems to improve accuracy.

GFM Innovations:

- Eco-friendly coatings and low-energy heat treatment.

- Dust/oil fume control systems compliant with local regulations.

- Trialing product traceability QR code systems.

- Expanding overseas support hubs in Southeast Asia and the Middle East.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

From raw steel to field-tested reliability, GFM adheres to professionalism, efficiency, and consistency. As a seasoned excavator track shoe manufacture specialist, GFM delivers not just steel parts but complete undercarriage solutions that extend machine life and lower maintenance.

Facing the future, whether your concern is extreme wear resistance or sustainable innovation, GFM stands ready with strong technical capability and industry insight.

If you’re looking for a long-term, reliable partner in the field of excavator track shoes, GFM is your ideal choice. Reach out today to discover how our solutions can support your heavy equipment operations worldwide.