Table of contents

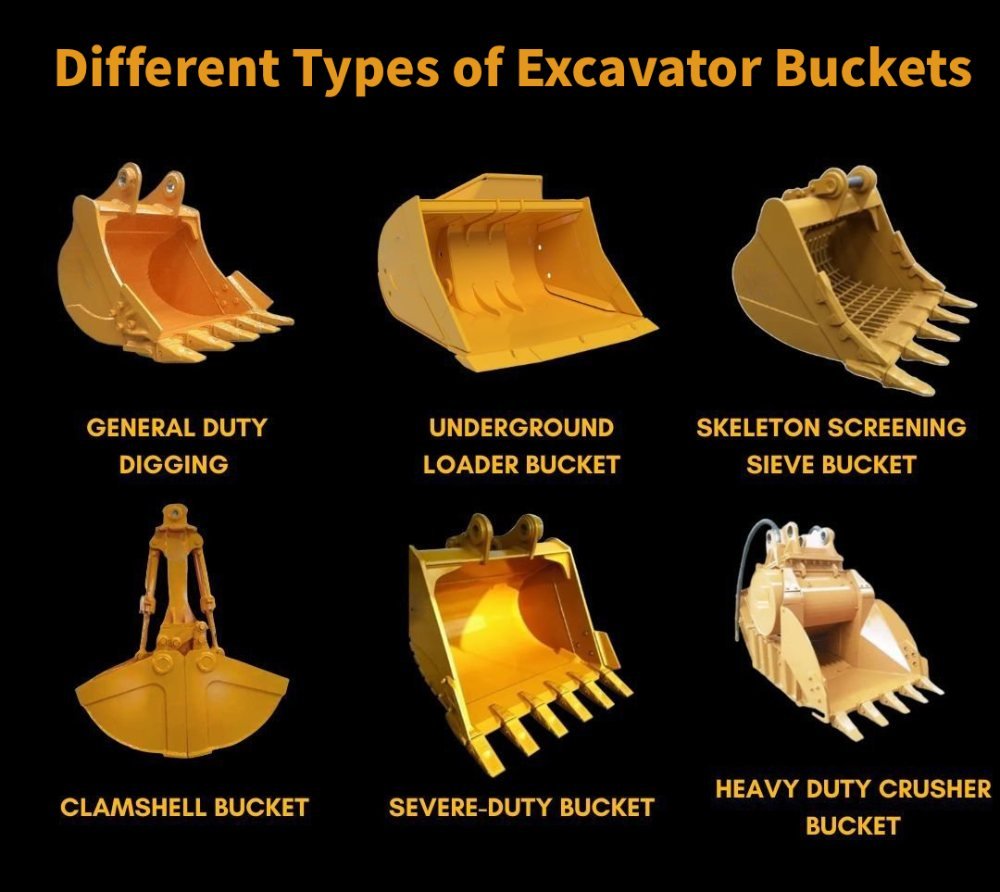

Understand Different Types of Excavator Buckets

Before selecting an excavator bucket, it is essential to have a comprehensive understanding of the different types of buckets. Each type varies in structure, material, and application scenario. Choosing the right one can significantly improve construction efficiency and extend the service life of your equipment.

Standard Buckets (General Purpose Buckets)

Standard buckets, also known as general-purpose buckets, are the most common type of excavator attachment. They are typically used for digging loose soil, gravel, and general construction materials, designed for versatility and durability. The cutting edge is relatively flat, suitable for most earthwork projects, maintaining stable performance under various conditions. According to the International Construction Machinery Association (ICMA), general-purpose buckets account for approximately 60% of daily earthmoving operations.

Heavy-Duty Buckets

Heavy-duty buckets are designed for high-intensity tasks, such as rock excavation, mining, and building demolition. The bucket plates are thick, side panels reinforced, and teeth made from high-wear steel, with heat treatment enhancing hardness and wear resistance. These buckets are usually paired with large excavators and can withstand higher impact and abrasion. According to GFM engineering case data, heavy-duty buckets have a service life 1.5–2 times longer than standard buckets.

Light-Duty Buckets

Light-duty buckets are mainly used for smaller excavators and precise operations, such as landscaping, trench digging, or municipal works. The structure is lighter for easier maneuverability, suitable for projects requiring precision. Advantages include higher mobility, reduced fuel consumption, and lower stress on the excavator.

Specialized Buckets

Specialized buckets include grapples, rock buckets, and cleanup buckets. Grapples handle wood, waste, or bulk materials; rock buckets are suitable for hard rock or concrete, usually equipped with wear-resistant teeth and thickened plates; cleanup buckets are used to clear debris or level the ground, with wide and flat cutting edges. When choosing specialized buckets, it is important to consider construction needs and material properties.

Determine the Right Bucket Size and Capacity

Bucket size and capacity directly affect digging efficiency and construction costs. Using an incompatible bucket can reduce efficiency or even damage the excavator.

Matching Bucket Volume with Excavator Tonnage

Bucket capacity is measured in cubic meters (m³). Different excavator tonnages require different bucket capacities. For example, a 20-ton excavator is suitable for a 1–1.2 m³ standard bucket, while a 50-ton large excavator can be matched with a 2–3 m³ heavy-duty bucket. GFM recommends leaving a 10–15% safety margin when choosing capacity to avoid overloading and prolong machine life.

Common Size Table and Applications

| Excavator Tonnage | Bucket Type | Recommended Capacity | Main Application |

|---|---|---|---|

| 5–10 tons | Standard | 0.3–0.6 m³ | Landscaping, municipal, small earthworks |

| 20–30 tons | Heavy-duty | 1–1.5 m³ | Construction, general earthworks |

| 40–50 tons | Heavy-duty | 2–3 m³ | Mining, demolition, heavy-duty work |

| Below 10 tons | Light-duty | 0.2–0.4 m³ | Precision excavation, trenching |

Estimating Work Efficiency and Load Capacity

Excavation efficiency = Bucket capacity × Cycles per hour × Material density

Example: 1.2 m³ bucket, 20 cycles per hour, material density ~1.6 t/m³ → theoretical hourly excavation ≈ 1.2 × 20 × 1.6 ≈ 38.4 tons. Accurate calculations help engineers choose the most suitable bucket and avoid resource waste.

Key Features to Consider When Choosing a Bucket

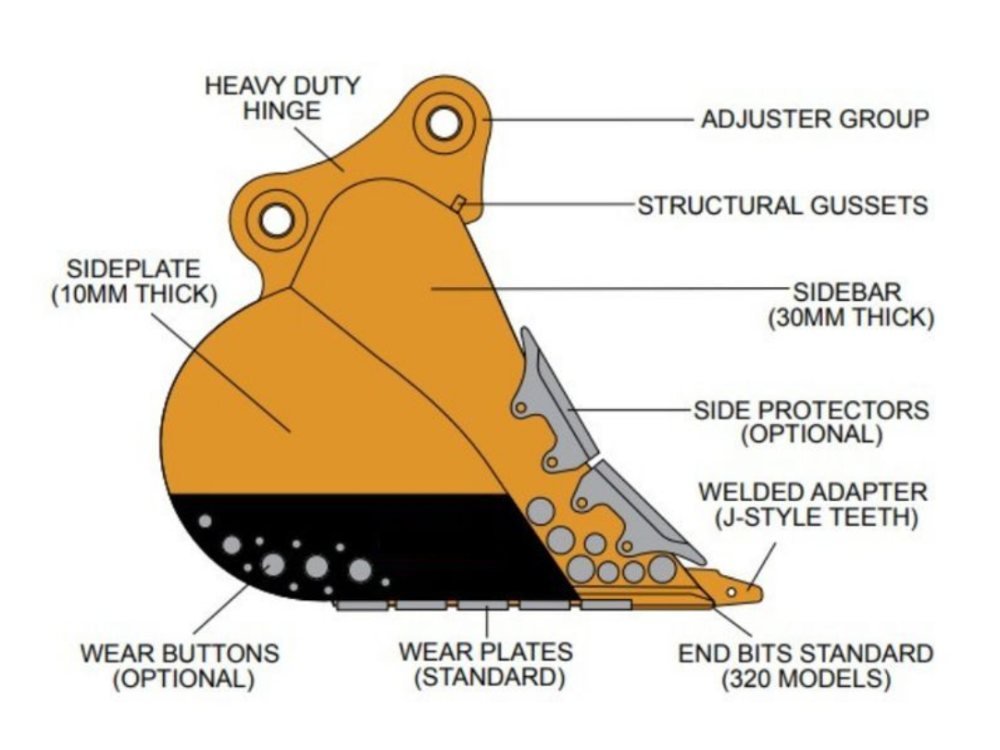

Choosing a bucket involves more than size and type. Design details directly affect service life and efficiency.

- Teeth Design: Bucket teeth contact soil and rock directly; shape, material, and mounting method influence digging performance. Common designs include pointed, flat, and replaceable teeth. Pointed teeth are suitable for hard materials, flat teeth for loose soil, and replaceable teeth facilitate maintenance and extend bucket life.

- Side and Bottom Plate Thickness: Thicker bottom and side plates enhance wear resistance. For heavy-duty tasks, bottom plate ≥ 20 mm and side plate ≥ 18 mm are recommended. GFM ensures through wear tests that buckets remain stable under high-intensity operations.

- Reinforcement and Wear-Resistant Materials: Bucket bottoms and sides often feature wear strips or reinforcement plates to improve durability. Wear-resistant steel with heat treatment prevents cracking and deformation. GFM heavy-duty buckets use HARDOX 450 steel, proven to have 50% longer service life than ordinary steel.

- Quick-Change Systems: Quick-change systems allow rapid replacement of buckets or teeth, improving construction efficiency and reducing downtime. For large projects, this system can save 20–30% of maintenance time.

- Brand and Manufacturer Reputation: Choosing experienced excavator bucket suppliers and an established Excavator Bucket Manufacturer is crucial. Professional manufacturers have complete production lines, strict quality control, and can provide the most suitable solutions based on engineering needs.

Match Buckets to Specific Working Conditions

Different working conditions require different bucket specifications. Precise matching improves efficiency and safety.

- Earthwork: Standard buckets are usually used, emphasizing versatility and wear resistance. Light-duty buckets are suitable for loose soil, while heavy clay requires thick plates and wear-resistant teeth.

- Rock/Mining Operations: Rock buckets require high-wear steel and sharp teeth with reinforced bottoms. GFM uses HARDOX steel in mining projects, improving wear resistance by 50%, with quickly replaceable teeth for continuous operation.

- Demolition: Buckets for demolition must resist impact. Thickened bottoms, reinforced sides, and shock-resistant teeth design are essential. Heavy-duty design ensures the bucket withstands concrete, bricks, and other hard materials.

- Dredging and Municipal Works: Dredging projects typically use cleanup or flat-edge buckets, with straight cutting edges for leveling riverbeds or trenches. Corrosion-resistant materials or coatings are recommended.

- Efficiency Tips: Engineers should consider material type, excavator tonnage, environment, project duration, and maintenance convenience when choosing a bucket. Properly matched bucket type and capacity can increase overall efficiency by 20–30%.

GFM: Your Trusted Excavator Bucket Manufacturer

GFM, as a professional Excavator Bucket Manufacturer, has 14 years of rich experience and extensive engineering case studies in the field of excavator buckets. Choosing a reliable partner ensures high-quality, durable, and dependable bucket solutions, improving construction efficiency and reducing maintenance costs.

- Production Capacity and Experience: GFM has modern production workshops and complete production lines, producing thousands of buckets annually. The experienced engineering team ensures that each bucket meets high standards in design, processing, and testing. Through rigorous production processes, GFM consistently provides durable and reliable bucket products for various construction conditions.

- Certification and Quality Standards: GFM buckets are ISO9001 certified and tested according to international wear standards (e.g., ASTM G65), ensuring excellent wear resistance and impact durability under high-intensity operations. Each bucket undergoes strict inspections to guarantee stable performance over long-term use.

- Customer Cases and Engineering References: GFM buckets have been widely used in mining, construction, demolition, and municipal projects worldwide. Rich engineering cases demonstrate product reliability and provide references for new clients, helping them quickly select the suitable bucket type and specification, improving procurement accuracy.

- Communication with excavator bucket suppliers: When selecting a bucket, maintaining detailed communication with suppliers is crucial. Clarifying project requirements, working environment, material types, and usage frequency helps suppliers provide the most suitable products and maintenance plans. GFM recommends providing excavator models, working conditions, and project duration to obtain accurate advice and reliable procurement solutions.

- After-Sales Support and Technical Assistance: GFM offers professional after-sales service and technical support to ensure any issues encountered during construction are resolved promptly. Whether a long-term client or first-time buyer, GFM provides full-process support from product selection to delivery, creating maximum value for customers.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Selecting the right excavator bucket not only affects construction efficiency but also directly impacts equipment lifespan and project costs. By analyzing bucket types, size and capacity, key features, and matching to working conditions, engineers can accurately choose the most suitable bucket.

Choosing an experienced, ISO-certified Excavator Bucket Manufacturer like GFM ensures reliable, durable buckets that meet construction requirements.

In practice, combining engineering needs with professional advice and thorough communication regarding bucket specifications will help achieve high-efficiency, low-cost construction goals. Whether for standard earthwork, mining operations, or demolition, scientifically selecting buckets is a key guarantee of project success.