Table of contents

The Importance of Undercarriage Parts in Excavators

The undercarriage system is the backbone of an excavator, directly affecting performance, efficiency, and safety. Understanding its significance helps operators make informed choices. Key points include:

- Functionality: Undercarriage parts, including track chains, bottom rollers, idlers, sprockets, and track shoes, bear the machine’s weight, transfer power, and maintain smooth movement. Any wear or failure can impact operational stability and precision.

- Economic Considerations: Maintenance of the undercarriage represents a significant portion of total repair costs. Choosing high-quality parts reduces repair frequency, lowers operating costs, and maximizes long-term investment value.

- Risk Factors: Using unsuitable or low-quality parts can lead to track derailment, chain breakage, or sprocket misalignment, causing downtime or safety hazards. Understanding the critical role of parts ensures safer operations.

- Impact on Machine Lifespan: Worn undercarriage components increase engine load and fuel consumption, shortening the excavator’s overall lifespan. Correct part selection and regular inspection can extend service life and enhance reliability.

Common Types of Excavator Undercarriage Parts

Before purchasing, it’s essential to understand the functions and characteristics of each component:

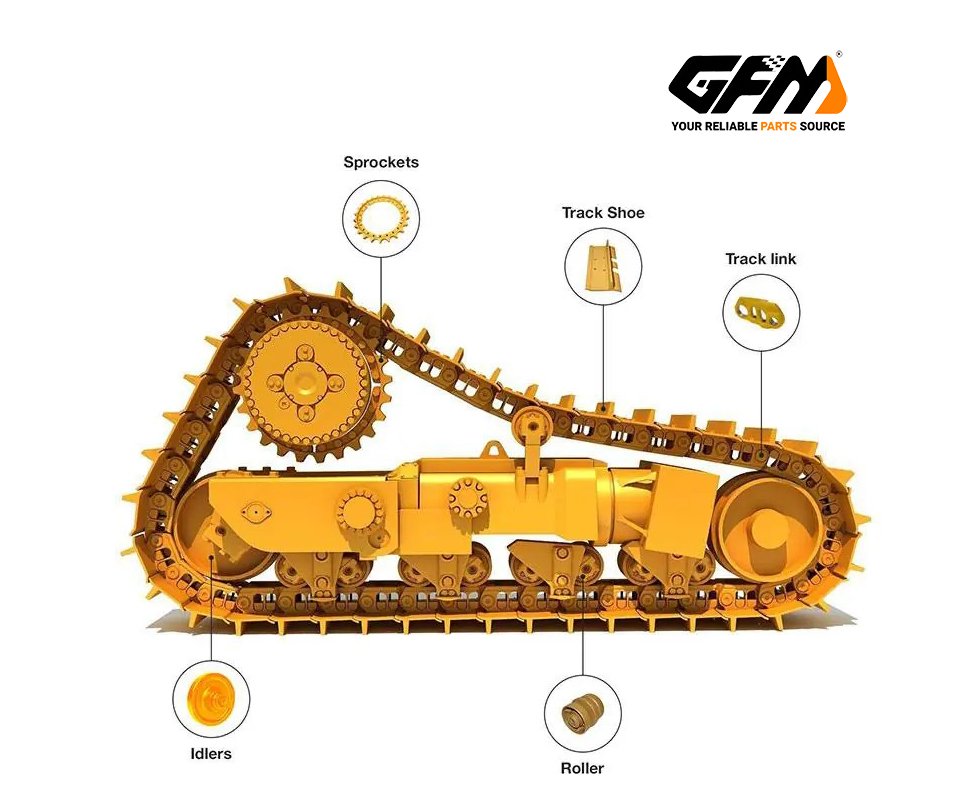

- Track Chain: The track chain is the core component for load-bearing and power transmission. It supports the machine’s weight and transmits engine power to the track shoes. Common wear includes loose links, increased pitch, or breakage, requiring timely replacement to prevent downtime.

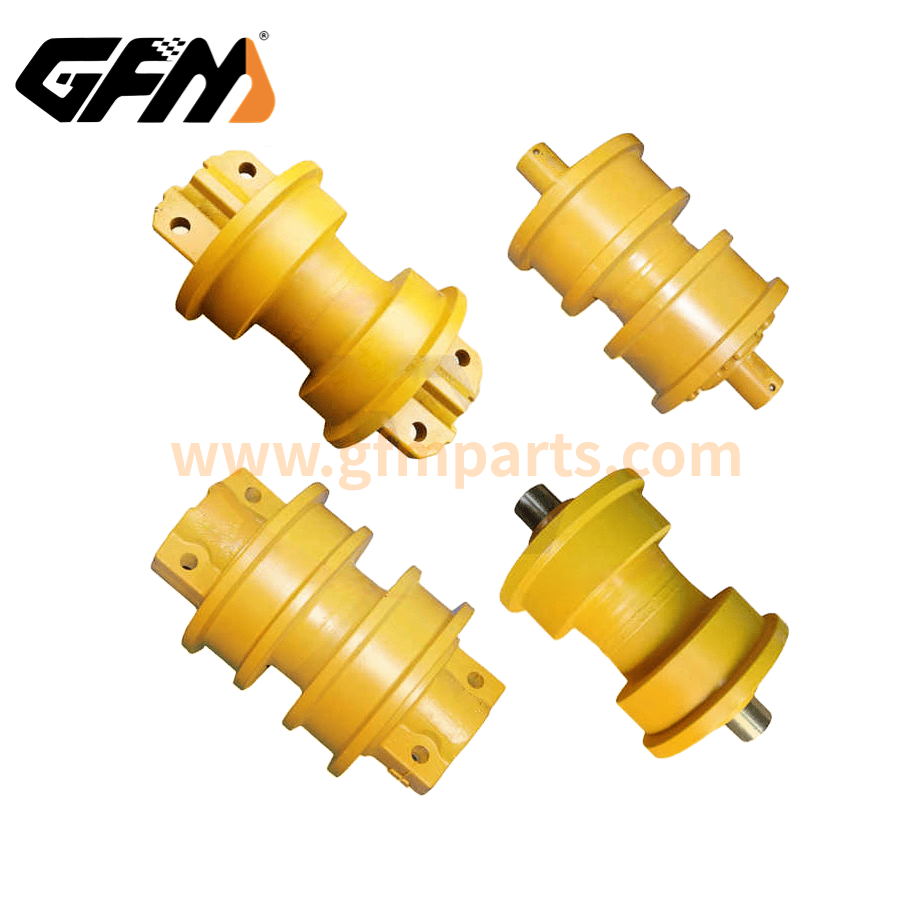

- Bottom Rollers: These support the machine’s weight and ensure smooth movement. Excessive wear can cause the track to sag, increase friction, and reduce operational accuracy.

- Idlers: Idlers maintain track tension and prevent derailment. Worn or damaged idlers can cause track slip, accelerating wear on other components.

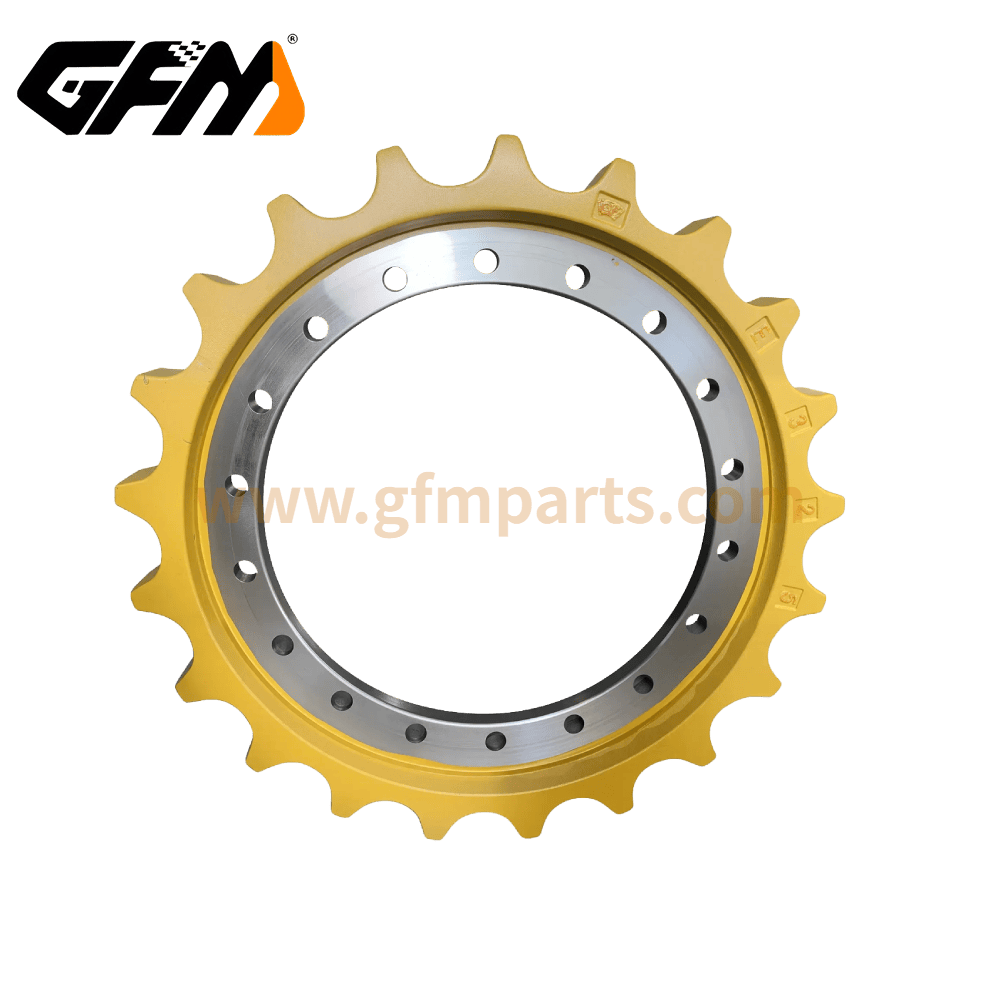

- Sprockets: Sprockets transfer engine power to the track chain. Worn or misaligned sprocket teeth reduce transmission efficiency and accelerate track wear.

- Track Shoes: Track shoes contact the ground directly. Wide shoes are suitable for soft soil, while high-strength, wear-resistant shoes are ideal for rocky terrain. Worn track shoes reduce traction and stability, affecting operational efficiency.

Understanding each part’s function and wear patterns helps determine replacement timing and maintenance schedules, preventing costly downtime.

Key Considerations When Choosing Undercarriage Parts

- Compatibility with Machine Model: Each excavator has unique undercarriage specifications. Parts must strictly match the brand and model. Before purchasing, check the model, track pitch, and bolt hole positions to ensure proper installation and stable performance. Mismatched parts can cause accelerated wear and operational issues.

- Work Environment: Different terrains require different parts. Soft soil needs wide track shoes to distribute weight and prevent sinking. Rocky or gravel terrain requires wear-resistant track chains and sturdy shoes. Wet or corrosive environments require corrosion-resistant materials. Choosing parts according to conditions extends lifespan and improves efficiency.

- Materials and Manufacturing Process: Material quality determines durability. High-quality parts are typically made of alloy steel and processed with forging and heat treatment to improve hardness and wear resistance. Uniform heat treatment reduces localized wear and ensures long-term reliability of the undercarriage system. Always check material grades, hardness, and heat treatment specifications.

- Balance Between Cost and Lifespan: Low-cost parts may reduce initial investment but increase maintenance and downtime. The ideal choice considers lifespan, maintenance frequency, and material quality, offering the best long-term value.

- Manufacturer Selection: Partnering with an experienced, certified excavator undercarriage parts manufacturer is crucial. A professional manufacturer ensures part precision and quality, provides stable supply and technical support, and reduces procurement risks, guaranteeing smooth operation.

How to Evaluate Part Quality: Practical Checklist

- Dimension Accuracy: Use calipers or measuring tools to check track chain pitch, bolt hole positions, and track shoe dimensions. Accurate parts prevent poor installation and excessive wear.

- Material Hardness and Wear Resistance: Test hardness (HRC) or wear resistance. High-quality track chains and shoes typically have HRC 45-50, suitable for heavy-duty conditions.

- Surface Treatment: Inspect heat treatment uniformity and anti-rust coating. Proper treatment reduces localized wear and corrosion, extending service life.

- Certifications and Standards: Choose parts certified to ISO9001, CE, or other recognized standards, ensuring manufacturing and inspection processes meet international benchmarks.

- Professional Inspection Tools: Tools like calipers, ultrasonic hardness testers, and thickness gauges help verify precision and material properties on-site.

- Manufacturer Reputation: Working with a reliable excavator parts manufacturer provides inspection reports and after-sales support, enhancing operational safety and efficiency.

Why Choosing a Professional Undercarriage Parts Manufacturer Matters

- Technical Capability: Professional manufacturers master forging, heat treatment, and CNC precision machining, ensuring part strength, hardness, and dimensional accuracy.

- Production and Delivery Capacity: Large-scale production ensures stable supply, avoiding downtime due to part shortages.

- After-Sales and Technical Support: Manufacturers provide installation guidance, troubleshooting, and maintenance advice, reducing costs and improving machine uptime.

- Industry Example: For instance, GFM has extensive experience producing excavator undercarriage components, strict quality inspection procedures, and provides inspection reports for every batch. Collaborating globally, they ensure reliable supply and technical support.

Partnering with a professional manufacturer guarantees high-quality parts, reduces maintenance risks, and increases operational efficiency and equipment lifespan.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Choosing the right excavator undercarriage parts is essential for ensuring machine performance, reducing operating costs, and extending service life. High-quality parts ensure smooth operation, minimize downtime, and improve work efficiency. Different terrains require components with specific characteristics—soft soil, rocky surfaces, or wetlands all demand suitable track chains, shoes, and sprockets. Collaborating with an experienced and certified excavator undercarriage parts manufacturer ensures accurate, durable parts, stable supply, and professional technical support. Considering part quality, environmental compatibility, and manufacturer reputation leads to durable components, lower maintenance costs, and safer, more efficient operations. Wise decisions bring immediate operational reliability and maximize long-term return on equipment investment.