Table of contents

- Why Excavator Undercarriage Parts Are Crucial for Performance and Safety

- Common Excavator Undercarriage Parts and Their Functions

- How to Identify High-Quality Excavator Undercarriage Parts

- How to Choose Reliable Excavator Undercarriage Parts Suppliers

- Practical Tips to Extend Excavator Undercarriage Parts Lifespan

Why Excavator Undercarriage Parts Are Crucial for Performance and Safety

The undercarriage system of an excavator bears the entire machine’s weight and operational stress, directly affecting efficiency and safety. This importance can be understood from the following aspects:

- Core Support and Load Bearing: Excavator undercarriage parts support the machine’s weight, including track chains, track shoes, bottom rollers, and top rollers, forming the foundation for stable operation. If these components are worn or lack sufficient strength, the machine may tilt or run unstably, increasing the risk of accidents.

- Impact on Fuel Efficiency and Operational Performance: Worn track chains or rollers increase friction, forcing the engine to consume more fuel to maintain operations. High-quality undercarriage parts ensure smooth power transmission, improving efficiency and reducing energy waste.

- Safety Assurance: Failure of undercarriage parts can lead to track slippage, jumping, or sprocket misalignment, directly threatening operator safety and worksite security. Poor maintenance is one of the main causes of downtime and accidents, making the choice of reliable excavator undercarriage parts suppliers essential.

- Effect on Machine Longevity: Excessive wear in the undercarriage can accelerate the damage of other components, such as increased hydraulic load or structural fatigue. Regular use of high-quality undercarriage parts and proper maintenance can significantly extend machine life and reduce long-term operational costs.

Common Excavator Undercarriage Parts and Their Functions

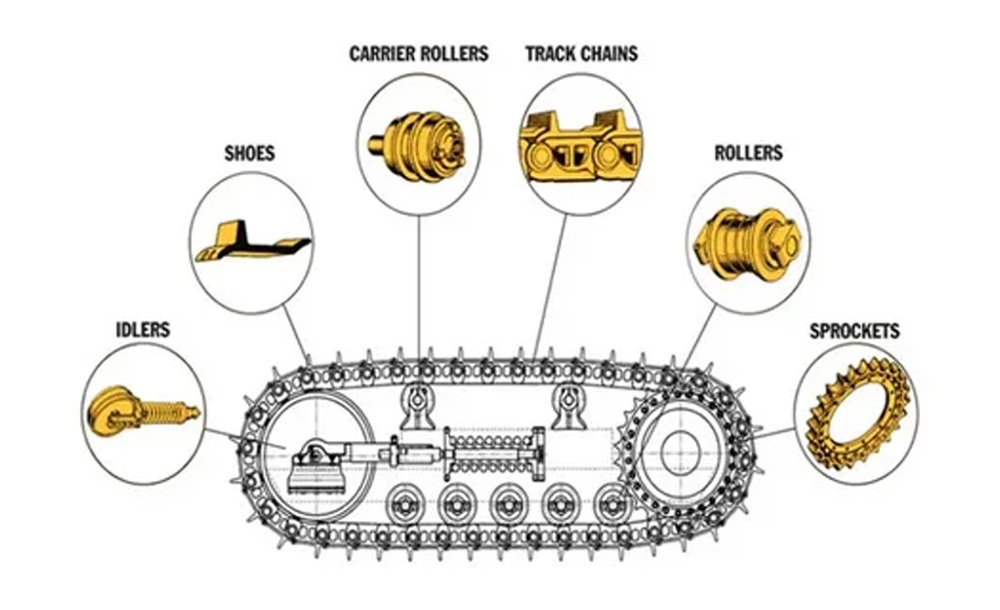

Understanding each component’s role helps assess its quality:

- Track Chains & Shoes: Track chains and shoes are the parts that contact the ground, bearing machine weight and providing traction. High-quality chains are made of high-strength alloy steel and heat-treated for wear resistance. Track shoes undergo surface strengthening to maintain grip on muddy, sandy, or rocky terrain.

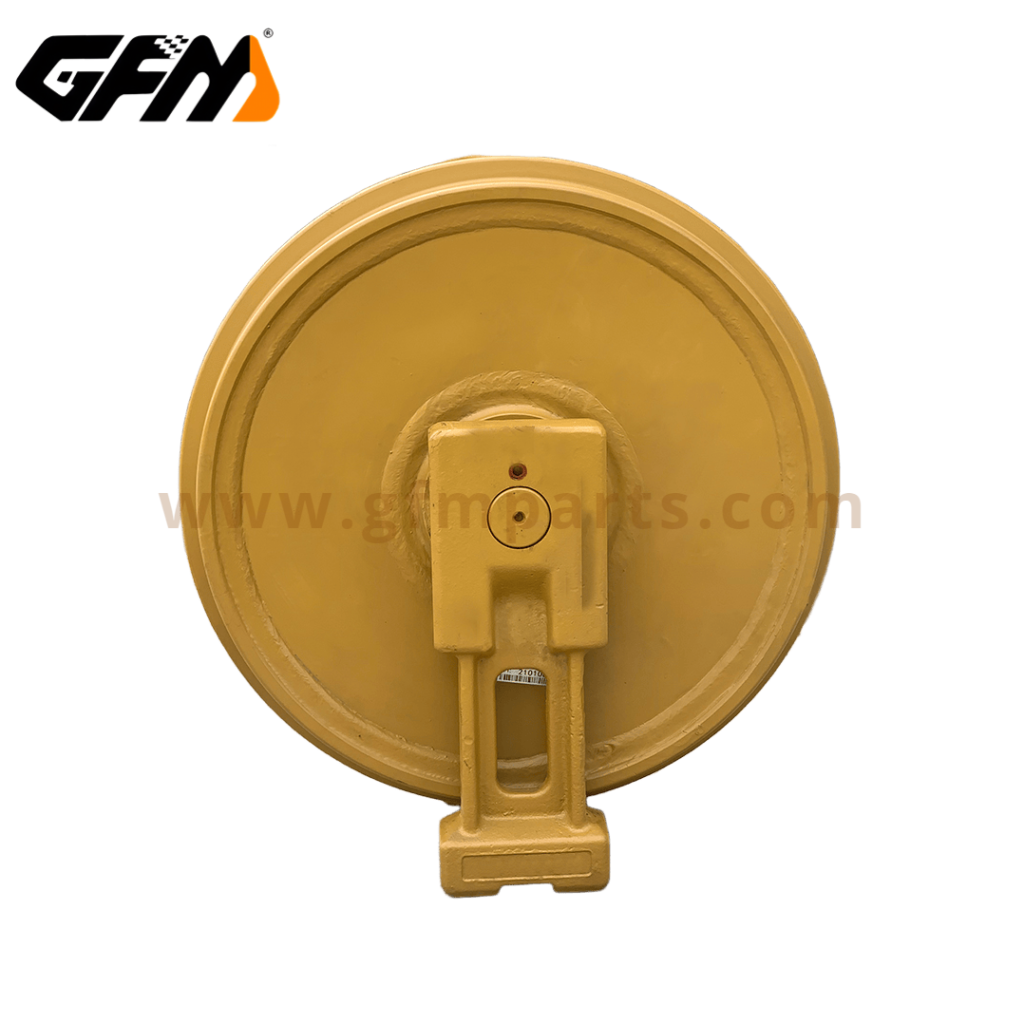

- Idlers & Sprockets: Idlers and sprockets maintain track tension and transmit power to the track chains. Quality idlers are made from high-strength steel and precision machined, while sprockets ensure smooth engagement and efficient power transfer.

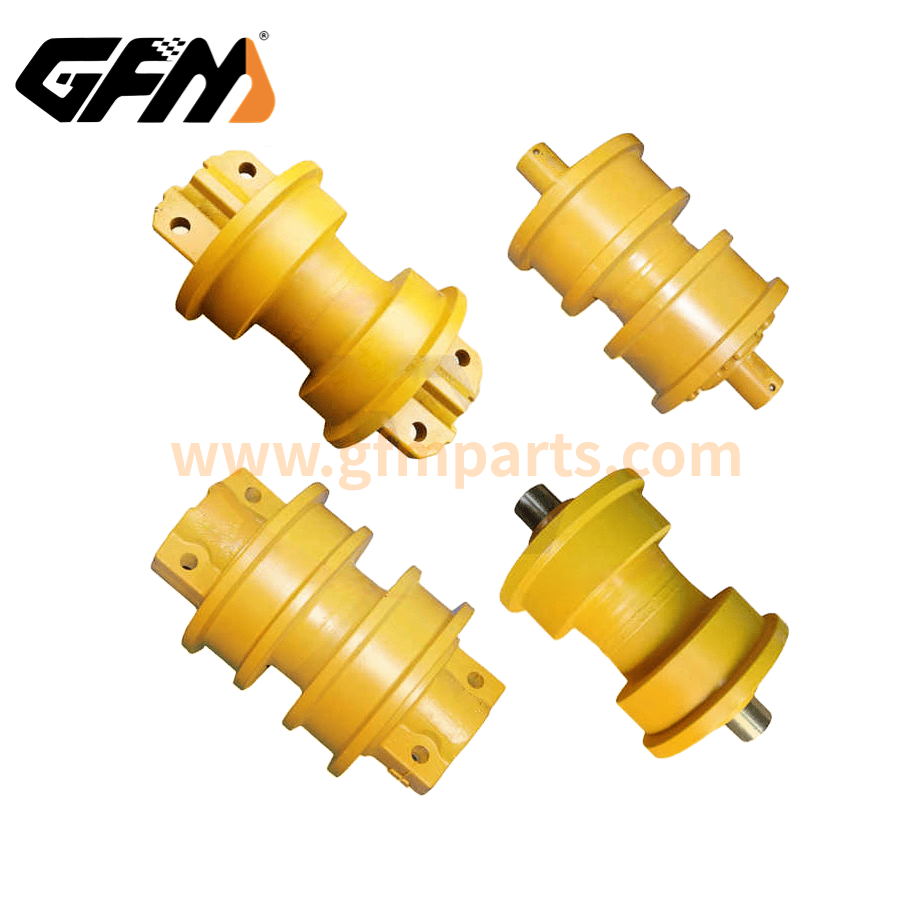

- Top & Bottom Rollers: Top and bottom rollers support the track chains, reduce friction, and carry machine weight. Low-quality rollers can suffer from bearing wear or cracks, causing uneven tracks or slippage. Checking roller hardness, bearing type, and lubrication method is critical.

- Track Bolts & Nuts: Though small, track bolts and nuts secure the entire track system. High-quality bolts use alloy steel with heat treatment to prevent loosening, and nuts often include lock washers to remain tight under heavy vibration.

Being familiar with the function and lifespan standards of each excavator undercarriage part helps make informed purchasing decisions.

How to Identify High-Quality Excavator Undercarriage Parts

Selecting high-quality components requires attention to materials, workmanship, precision, and wear resistance:

- Material Quality: High-quality undercarriage parts typically use high-strength alloy steel with heat treatment and quenching to improve hardness and durability. Chains, track shoes, and rollers should generally reach HRC 50–55 for high-stress conditions.

- Precision Manufacturing: Precision machining ensures compatibility with the host machine. CNC machining controls chain link dimensions, sprocket tooth spacing, and hole positions, minimizing installation gaps and preventing track slippage.

- Surface Treatment: Shot peening, plating, or anti-corrosion treatments extend component life and protect against rust in muddy or humid environments.

- Compatibility: Different excavator models require precise undercarriage specifications. Components must match the machine’s model to prevent operational issues.

- Wear Testing Methods: Hardness testing, metallographic analysis, or simulated wear testing can scientifically evaluate component lifespan, ensuring reliable excavator undercarriage parts selection.

How to Choose Reliable Excavator Undercarriage Parts Suppliers

Choosing high-quality components also involves selecting experienced and trustworthy suppliers:

- Experience and Reputation: Suppliers with over 10 years in the industry and long-term client cases demonstrate reliability. Experienced suppliers offer precise solutions and understand different excavator models.

- Certifications: ISO9001, CE, or OEM authorization ensures standardized manufacturing processes and controllable product quality.

- Production Capacity and Delivery: Large projects require bulk purchases. Suppliers must have stable capacity and timely delivery to maintain project schedules.

- After-Sales and Technical Support: Reliable suppliers provide warranties, installation guidance, and spare parts support. Quick technical response reduces downtime in case of issues.

- Global Client References: Suppliers serving major international projects or collaborating with global brands demonstrate product quality and credibility.

Chinese suppliers often provide cost efficiency and flexibility, while international suppliers emphasize certification standards and brand reputation. Selecting the right supplier depends on project needs.

Practical Tips to Extend Excavator Undercarriage Parts Lifespan

Even with high-quality components, proper use and maintenance are essential:

- Routine Inspection: Check track chains, rollers, and bolts daily or weekly. Address cracks, looseness, or abnormal wear immediately.

- Proper Track Tension Adjustment: Over-tightened tracks increase friction and wear; loose tracks may slip. Adjust tension according to the manufacturer’s guidelines to extend component life.

- Good Operating Habits: Avoid sharp turns, prolonged high-speed travel, or operating over sharp rocks to reduce uneven stress and damage.

- Lubrication and Cleaning: Regularly remove mud and debris, and lubricate chains and rollers to minimize friction and corrosion.

- Replacement Schedule Management:Set replacement plans based on operating hours, terrain conditions, and wear levels. Preventive replacement avoids downtime and secondary damage.

Proper operation and maintenance can extend component life by 20%–30%, significantly lowering maintenance costs.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

High-quality excavator undercarriage parts are essential for safe and efficient excavator operation. Understanding the function, material, manufacturing process, and wear standards of each component—and choosing experienced, certified, and responsive excavator undercarriage parts suppliers—enhances equipment reliability, reduces downtime, and lowers long-term costs.

Additionally, routine inspection, proper operation, lubrication, and scheduled replacement are vital for prolonging component life and ensuring project success. Combining high-quality parts with good maintenance practices is a smart strategy to keep excavators running at peak performance.

By applying the identification methods, supplier selection criteria, and maintenance tips discussed, users can confidently select and manage excavator undercarriage parts, avoiding common issues and ensuring their machines perform optimally.