Excavator track assembly installation matters and processes

Preliminary preparation

- Environmental inspection: Before installation, ensure that the working environment is safe, the ground is flat, and there are no sharp objects to prevent the track from being damaged during installation.

- Tool preparation: Prepare the required installation tools, such as wrenches, pipe clamps, hammers, etc., to ensure that the tools are of reliable quality and avoid damage to the tools during installation.

- Track inspection: Check whether the new track is damaged and ensure that all bolts, nuts and other parts are complete and in good condition.

Installation steps

- Positioning adjustment: Park the excavator on a flat ground, adjust the distance between the excavator and the track, and ensure that there is enough space for installation.

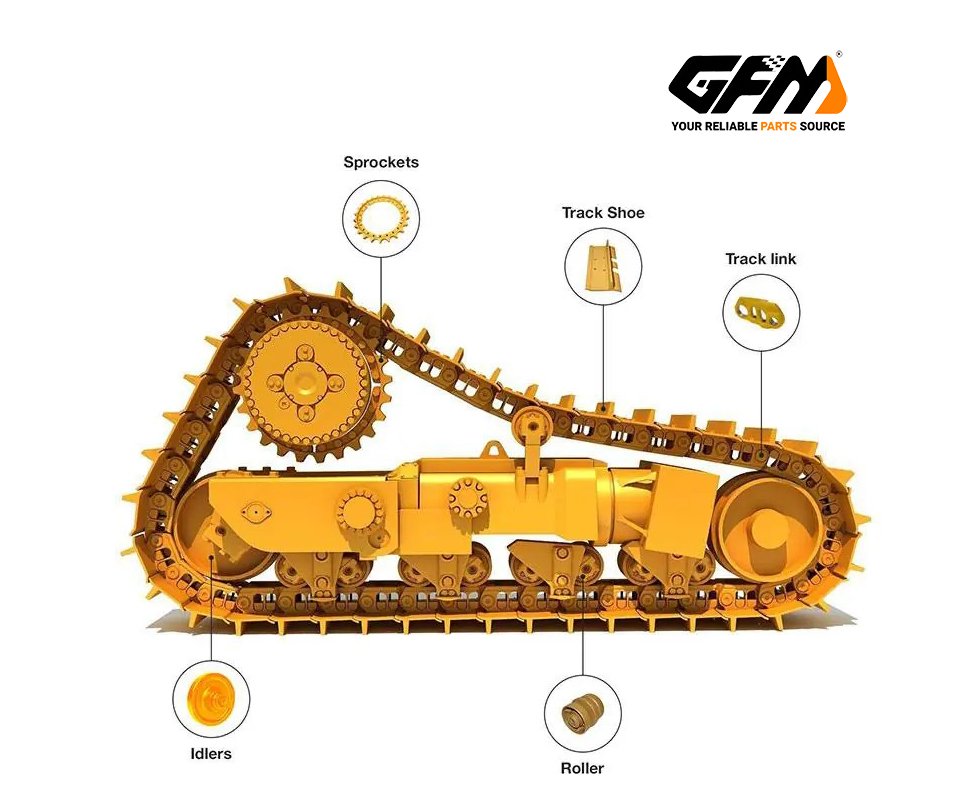

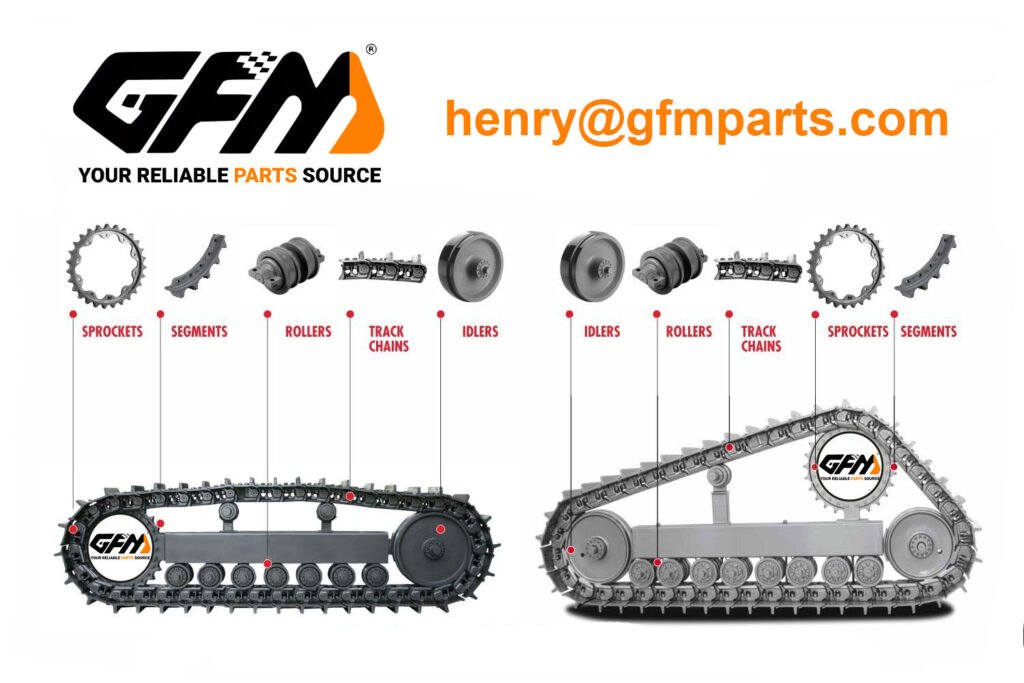

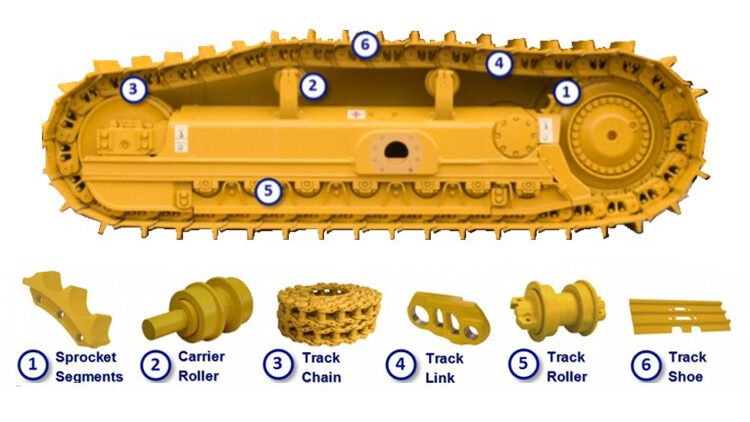

- Track laying: Lay the track flat under the excavator, and ensure that the track chain links correspond to the excavator sprocket and drive wheel.

- Install the drive wheel: Fix one end of the track on the drive wheel and tighten the bolts with a wrench or pipe clamp.

- Guide the track: Guide the track around the guide wheel and supporting wheel manually or with auxiliary equipment to ensure that the track tension is appropriate.

- Install the track pin: Insert the track pin into the track link, make sure the track pin is in place, and tap it gently with a hammer to ensure it is tight.

- Check and adjust: After installation, start the excavator, drive slowly, and check whether the track is running smoothly without abnormal noise or jamming.

Installation precautions

- Safe operation: During the installation process, always wear safety equipment to avoid injury. The track is heavy, so it is recommended that multiple people work together to ensure safety and efficiency. Follow the installation guide provided by the manufacturer to ensure standard operation.

- Avoid damage: During the installation process, avoid using violent means to avoid damaging the track or excavator parts.

- Check the hole position: Before installation, carefully check whether the hole positions on the track and the excavator correspond to each other to ensure that there is no misalignment during installation.

- Adjust the tension: Moderate track tension is the key to ensuring the smooth operation of the excavator. Too tight or too loose may cause premature wear or damage to the track.

Behavior to avoid to keep the track in the best condition

- Unilateral wear: Due to the influence of operating habits or working environment, it is easy to cause unilateral wear of the track. The machine position should be changed regularly to reduce excessive wear on one side.

- Reduce sharp turns: Frequent sharp turns can easily cause uneven force on the track.

- Avoid climbing with heavy loads: Especially on muddy ground, climbing with heavy loads will accelerate the wear of the track and drive wheel.

- Irregular operation: Repeatedly traveling on inclined ground or turning suddenly during long-term load operation can easily cause track wear. Scientific operating specifications should be strictly followed to avoid irregular operations.

- Neglecting maintenance: Neglecting the maintenance of the track will shorten its service life. The track should be checked regularly and loose bolts, nuts and other parts should be reinforced.

- Overload use: Avoid using the excavator for a long time under extremely harsh conditions to reduce the risk of track wear and damage.

Maintain and maintain the track assembly

Regular inspection and replacement

- Bolts and nuts: Regularly check whether the bolts, nuts and other parts on the track are loose or damaged, and replace or reinforce them in time.

- Track shoes: Check whether the track shoes are cracked or severely worn, and replace the severely worn track shoes in time.

- Track pin: Check if the track pin is loose or damaged, and replace it in time to ensure stable operation of the crawler.

Cleaning and lubrication

- Regular cleaning: Clean the dirt, sand and other debris on the crawler regularly to avoid wear and tear on the crawler.

- Lubrication and maintenance: Lubricate the crawler chain links, supporting wheels, guide wheels and other components regularly to reduce friction and extend service life.

Storage and protection

- Avoid long-term exposure: When not in use for a long time, the excavator should be parked indoors or under a cover to avoid long-term exposure of the crawler to harsh environments.

- Regular inspection and maintenance: Even when not in use, the crawler status should be checked regularly to ensure that it is in good condition.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

The correct installation and maintenance of excavator tracks is an important part of ensuring the efficient operation of the equipment. By following the installation steps and maintenance suggestions provided in this article, you can effectively extend the service life of the tracks and reduce operating costs. If you have more questions about the selection or maintenance of excavator tracks, please feel free to contact GFM’s professional excavator track supplier for professional advice.