The excavator is an important equipment in engineering machinery, and the maintenance of its undercarriage system is directly related to the normal operation and service life of the equipment. As the supporting structure of the excavator, the chassis bears the weight of the entire equipment, so good maintenance is essential. In the maintenance of the excavator undercarriage, especially the maintenance of the four-wheel and track system, it can not only improve work efficiency, but also effectively reduce the occurrence of failures.

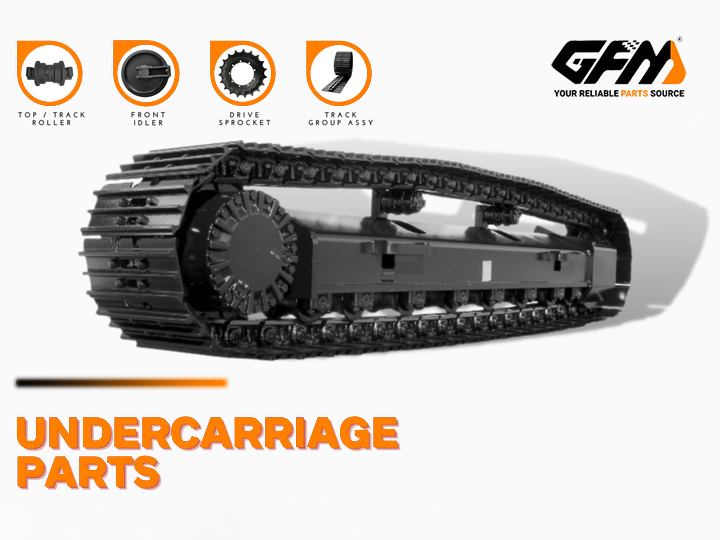

The structure and function of the excavator undercarriage part

The four-wheel and one belt are the core part of the excavator undercarriage, mainly composed of four wheels and a crawler. The wheel part is usually located at the front and rear ends, and the crawler is connected to the wheel by a chain. The four-wheel and one belt mainly undertake the following tasks:

- Support the excavator: carry the weight of the machine and provide stable support.

- Traction: transmit power from the engine to the ground through the crawler system, allowing the excavator to walk freely.

- Operational flexibility: allows the excavator to move freely on uneven ground.

The importance of excavator undercarriage maintenance

- Improve the stability and safety of the excavator.

- Extend the life of the track and reduce maintenance costs.

- Improve fuel efficiency and reduce operating costs.

- Reduce failures and avoid downtime caused by chassis problems.

Maintenance methods for excavator undercarriage

Check the wear of wheels and tracks

Regularly check the wheels and tracks of the four-wheel-one-belt for excessive wear, cracks or other damage. Especially under high-intensity working conditions, the wear of wheels and tracks will accelerate. If the track is found to be cracked or severely worn, it should be replaced in time. If the wheel bearings are severely worn, they should also be replaced or repaired.

Operation method:

- Check the tension of the track daily to ensure that it is not too loose or too tight.

- Check the wheel bearings and rollers to ensure that there is no abnormal noise or overheating.

- Clean the wheels and tracks to avoid accumulation of mud, sand and stones.

Maintain proper tension of the track

Track tension has an important impact on the performance of the excavator. Tracks that are too tight or too loose will affect the stability of the chassis and even cause the track to break. The ideal tension should be kept within the range recommended by the manufacturer.

How to operate:

- Use the tensioning device to adjust the tension of the track regularly.

- Tracks that are too loose can easily cause slippage and increase fuel consumption.

- Over-tightening can cause premature wear of the track and affect the driving stability of the excavator.

Clean the undercarriage and tracks

The undercarriage and tracks are prone to accumulate dirt, sand and other debris, which not only increase the wear of the chassis, but also may affect the movement performance of the excavator. Therefore, keeping the chassis clean is a vital maintenance step.

How to operate:

- Rinse the tracks and wheels with a high-pressure water gun regularly, especially in muddy and sandy working environments.

- Clean the debris around the chain to prevent it from accumulating on the chain or other moving parts.

Check and replace the hydraulic oil

The quality of the hydraulic oil directly affects the operating efficiency of the chassis system. Check the quality of the hydraulic oil regularly to ensure that its viscosity and cleanliness meet the requirements. If the hydraulic oil has deteriorated or contaminated, it should be replaced in time.

How to operate:

- Check the oil level and cleanliness of the hydraulic oil regularly.

- Replace the hydraulic oil at the time interval specified in the equipment manual.

- Pay attention to the cleaning and replacement of the hydraulic oil filter to avoid oil circuit blockage.

Check the lubrication system of the undercarriage

The lubrication system of the chassis is the key to ensure the normal operation of the four-wheel belt. Insufficient or inappropriate lubrication will lead to increased wear of components and even failure.

How to operate:

- Regularly check the amount of grease at each lubrication point of the chassis, especially the contact point between the axle and the track.

- Use lubricating grease that meets the requirements of the equipment and lubricate according to the cycle recommended in the equipment manual.

Check the suspension system and shock absorber

The suspension system and shock absorber are another important part of the excavator chassis. They can absorb vibrations during work and reduce the burden on the chassis. Check the condition of these parts regularly to ensure that they are working properly.

How to operate:

- Check the shock absorber for oil leakage or aging every month to ensure that it maintains the best buffering effect.

- Check the springs and shock absorbers of the suspension system to confirm that they are not abnormally damaged.

Precautions for excavator undercarriage maintenance

- Prevent overload: Avoid long-term overload operation, which will accelerate the wear of chassis components.

- Avoid violent operation: Frequent rapid acceleration or sudden braking is not recommended, which will cause damage to the chassis structure.

- Regularly check the undercarriage: Perform a comprehensive inspection regularly, especially after high-intensity operations, and thoroughly check the chassis to ensure that there are no potential problems.

- Maintain a clean environment: During the cleaning process, avoid using overly strong detergents or high-pressure water guns to directly spray certain sensitive parts.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Excavator undercarriage maintenance is a vital part of excavator undercarriage maintenance. Correct maintenance methods can not only extend the service life of the undercarriage system, but also improve the working efficiency of the excavator and reduce maintenance costs. Through regular inspection, cleaning and lubrication, ensure the stability of the crawler and wheel systems, avoid excessive wear and failure, and ensure the good condition of the equipment in long-term operation. Following the above maintenance tips, the excavator’s four-wheel and one-belt system will continue to play its important role and provide strong support for various construction projects.